Silicate ester modified polyamide reverse osmosis composite membrane and preparation method thereof

A reverse osmosis composite membrane, silicate technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as water flux reduction, and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

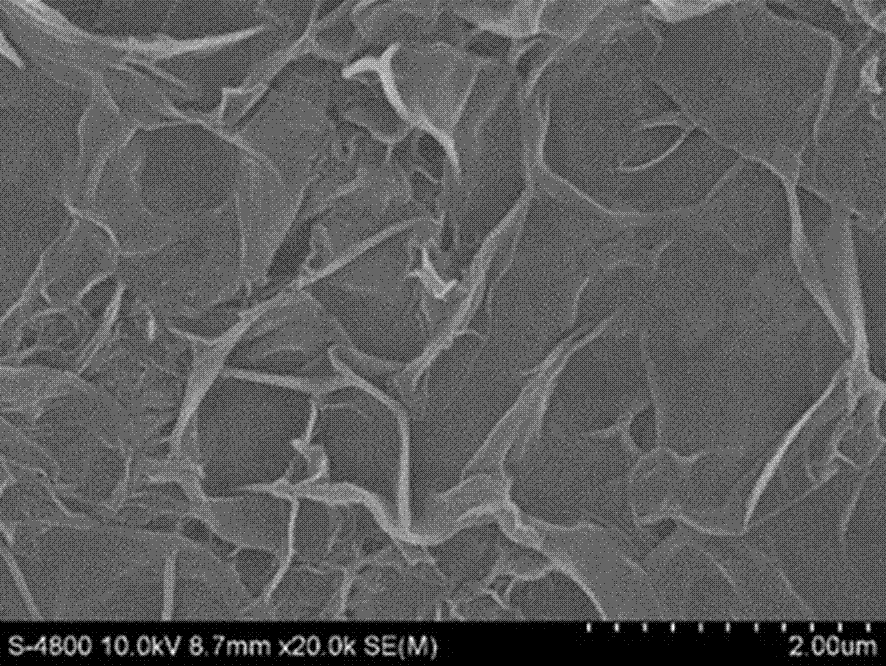

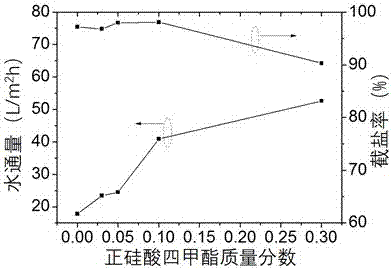

[0036] Tetraethyl orthosilicate was added to the organic phase to assist interfacial polymerization for 5 minutes to prepare a polyamide reverse osmosis composite membrane.

[0037] (1) Fix the polysulfone support layer on the clip with the facing up, first pour the aqueous phase solution containing m-phenylenediamine (2wt% m-phenylenediamine) on the surface of the membrane, it is advisable to immerse the membrane surface, and use a rubber stick on the surface of the membrane. After the membrane surface was rolled back and forth for 2 minutes, the excess aqueous phase solution on the surface of the support layer was removed.

[0038] (2) After draining, submerge an appropriate amount of organic phase containing trimesoyl chloride and tetraethyl orthosilicate (0.1wt% trimesoyl chloride, 0 ~ 35wt% TEOS) on the surface of the membrane and contact the water phase for 5 minutes, The interfacial polymerization reaction is carried out under the auxiliary condition of tetraethyl ester...

Embodiment 2

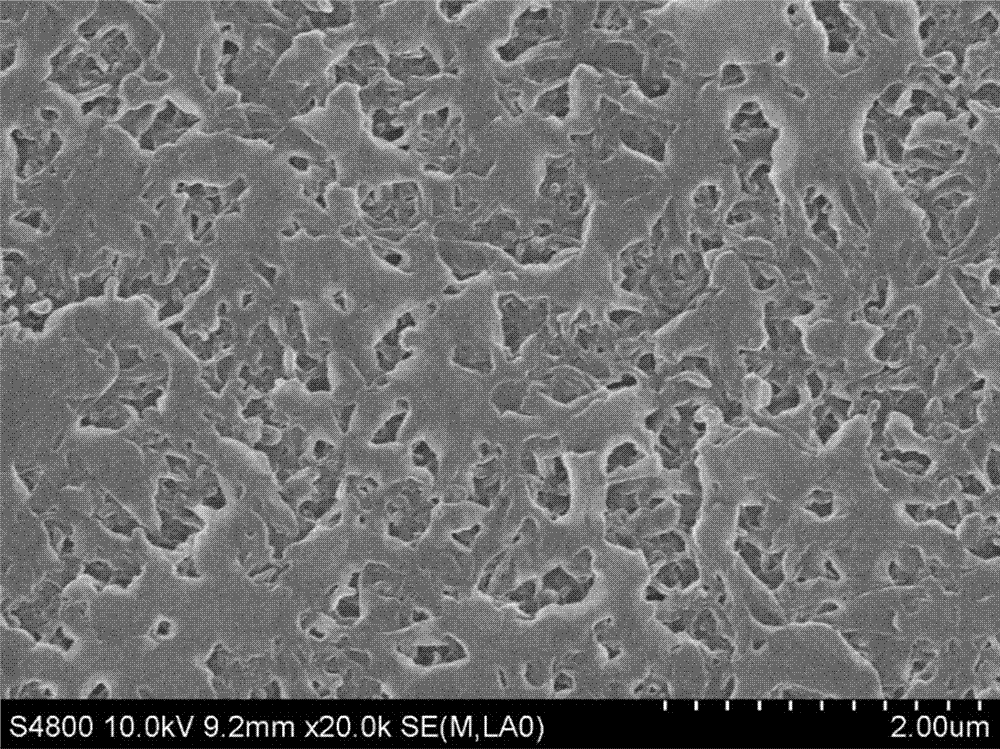

[0042] Adjust the pH to 10.0, add tetramethyl orthosilicate to the organic phase to assist interfacial polymerization for 1 min, and prepare a polyamide reverse osmosis composite membrane.

[0043] (1) Fix the polysulfone support layer on the clip with the facing up, first pour the aqueous phase solution containing m-phenylenediamine (2wt% m-phenylenediamine, pH=10.0) on the membrane surface, preferably to immerse the membrane surface, Use a rubber rod to roll back and forth on the membrane surface for 2 minutes to remove excess aqueous solution on the surface of the support layer.

[0044] (2) After draining, an appropriate amount of organic phase (0.1wt% trimesoyl chloride, 0~0.3wt% TMOS) containing trimesoyl chloride and tetramethyl orthosilicate was immersed in the membrane surface and contacted with the water phase for 1 min. The interfacial polymerization reaction is carried out under the auxiliary condition of tetramethyl ester to obtain the polyamide active layer, and ...

Embodiment 3

[0048] Adjust the pH to 10.0, add tetramethyl orthosilicate to the organic phase to assist interfacial polymerization for 2 minutes, and prepare a polyamide reverse osmosis composite membrane.

[0049] (1) Fix the polysulfone support layer on the clip with the facing up, first pour the aqueous phase solution containing m-phenylenediamine (2wt% m-phenylenediamine, pH=10.0) on the membrane surface, preferably to immerse the membrane surface, Use a rubber rod to roll back and forth on the membrane surface for 2 minutes to remove excess aqueous solution on the surface of the support layer.

[0050] (2) After draining, an appropriate amount of organic phase (0.1wt% trimesoyl chloride, 0~1.6wt% TMOS) containing trimesoyl chloride and tetramethyl orthosilicate was immersed in the membrane surface and contacted with the water phase for 2 minutes. The interfacial polymerization reaction is carried out under the auxiliary condition of tetramethyl ester to obtain the polyamide active lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com