Preparation method for pseudo-boehmite and alumina

A technique of pseudo-boehmite and alumina, applied in the field of preparation of pseudo-boehmite and alumina, can solve the problems of uneven pore size, low crystal phase purity, unstable products, etc., and achieves short reaction time, alcohol and other problems. The effect of high purity and single crystal phase of aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

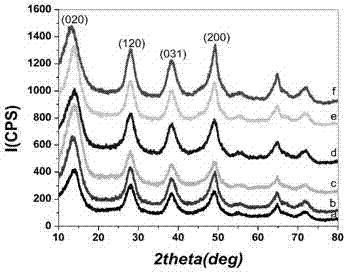

Embodiment 1

[0024] Put 108g aluminum ingots and 200g higher fatty alcohol into a 5L kettle with a condenser, heat it to 110°C, and after producing obvious bubbles, add 1136g higher fatty alcohol dropwise. After the reaction, add 400g trimethylbenzene to the flask and heat to At 110°C, filter to obtain a mixture of aluminum alkoxide and trimethylbenzene. Add 126 mL of deionized water to the kettle and raise the temperature to 80°C. A mixture of aluminum alkoxide and trimethylbenzene at a temperature of 80°C was added dropwise to the kettle while stirring was started, and the addition was completed in 30 minutes. The mixture of fatty alcohol and trimethylbenzene produced by the hydrolysis of aluminum alkoxide is drawn out from the flask. Add 90 mL of deionized water to the kettle and increase the temperature to 85°C, after aging for 12 hours. The remaining alcohol and solvent are evaporated, and spray dried to obtain 240 g of pseudo-boehmite. After XRD, differential thermal and ICP-MS ana...

Embodiment 2

[0026] Put 108g aluminum flakes and 200g higher fatty alcohol into a 5L kettle with a condenser, heat it to 110°C and generate obvious bubbles, add 1136g higher fatty alcohol dropwise, add 400g trimethylbenzene to the flask after the reaction, and heat to At 110°C, filter to obtain a mixture of aluminum alkoxide and trimethylbenzene. Add 126 mL of deionized water to the kettle and raise the temperature to 80°C. A mixture of aluminum alkoxide and trimethylbenzene at a temperature of 80°C was added dropwise to the kettle while stirring was started, and the addition was completed in 30 minutes. The mixture of fatty alcohol and trimethylbenzene produced by the hydrolysis of aluminum alkoxide is drawn out from the flask. Add 180 mL of deionized water to the kettle and raise the temperature to 85°C, after aging for 12 hours. The remaining alcohol and solvent are distilled off, and spray-dried to obtain 240 g of pseudo-boehmite. After XRD, differential thermal and ICP-MS analysis, ...

Embodiment 3

[0028] Put 108g aluminum wire, 200g higher fatty alcohol into a 5L kettle with condenser, heat it to 110°C, and after producing obvious bubbles, add 1136g higher fatty alcohol dropwise, add 400g trimethylbenzene to the flask after the reaction, and heat to At 110°C, filter to obtain a mixture of aluminum alkoxide and trimethylbenzene. Add 126 mL of deionized water to the kettle and raise the temperature to 85°C. A mixture of aluminum alkoxide and trimethylbenzene at a temperature of 85°C was added dropwise to the kettle while stirring was started, and the addition was completed in 30 minutes. The mixture of fatty alcohol and trimethylbenzene produced by the hydrolysis of aluminum alkoxide is drawn out from the flask. Add 450 mL of deionized water to the kettle and raise the temperature to 90°C and age it for 10 hours. The remaining alcohol and solvent are distilled off, and spray-dried to obtain 240 g of pseudo-boehmite. After XRD, differential thermal and ICP-MS analysis, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com