Slope-repairing thick-layer matrix and production method thereof

A production method and substrate technology, applied in planting substrates, botanical equipment and methods, culture media, etc., can solve the problems of destroying original vegetation, bare land, and bare land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

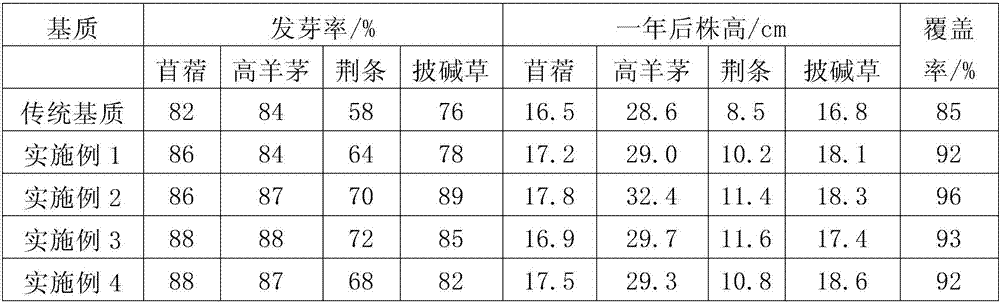

Examples

Embodiment 1

[0018] (1) Take each raw material of described weight ratio: 35% of phosphate rock tailings and power plant fly ash, 53% of corn stalks, 5% of illite tailings, 3% of slow-release fertilizers, 3% of polyacrylamide, polyacrylamide Bacillin 0.2%, gibberellin 0.8%;

[0019] (2) Dissolving the carbendazim in the weight ratio with a little water, evenly spraying it on the surface of corn stalks of corresponding weight, and stacking for 5 days, the material is ready for use;

[0020] (3) Mix the above materials with the corresponding weight ratio of phosphate rock tailings, power plant fly ash, illite tailings, slow-release fertilizers, polyacrylamide and brown mycin to obtain the thick layer of slope repair matrix.

Embodiment 2

[0022] (1) Take the raw materials of the weight ratio: 20% of phosphogypsum and potassium silicate tailings, 52% of corn stalks and cotton stalks, 8% of chlorite tailings, 4% of slow-release fertilizers, γ- PGA5%, chlorothalonil 0.5%, auxin 0.5%;

[0023] (2) Dissolving the chlorothalonil in the weight ratio with a little water, evenly spraying on the surface of corn stalks and cotton stalks of corresponding weight, and stacking for 5 days, the materials are ready for use;

[0024] (3) Mix the above materials with corresponding weight proportions of phosphogypsum, potassium silicate ore tailings, chlorite tailings, slow-release fertilizers, γ-PGA and auxin to obtain the slope restoration thickness layer matrix.

Embodiment 3

[0026] (1) Weigh each raw material of said weight ratio: 30% of phosphogypsum, 57% of rice straw and traditional Chinese medicine residue, 5% of kaolinite tailings, 5% of slow-release fertilizer, 2% of carboxymethyl cellulose, Bordeaux mixture 0.3%, Cytokinin 0.7%;

[0027] (2) Dissolving the Bordeaux mixture of the weight ratio with a little water, evenly spraying on the surface of the corresponding weight rice straw and traditional Chinese medicine slag, and after stacking for 5 days, the material is ready for use;

[0028] (3) Evenly mix the above materials with phosphogypsum, kaolinite tailings, slow-release fertilizer, carboxymethyl cellulose and cytokinin in the corresponding weight ratio to obtain the thick layer matrix for slope restoration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com