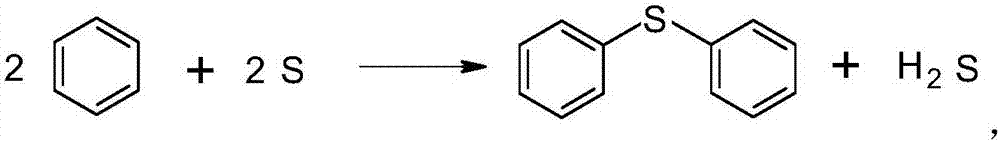

Synthetic method of diphenyl sulfide

A synthetic method and technology of diphenyl sulfide, applied in the direction of sulfide preparation, organic chemistry, etc., can solve the problems of high production cost, difficulty in forming production capacity, low yield, etc., and achieve the effect of less waste water and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a four-neck flask equipped with a condenser, a water separator, a thermometer and a tail gas treatment device (tail gas produced by the absorption reaction of the sodium hydroxide solution), add 200g of benzene and 97g of aluminum trichloride, heat up to 50°C, and Under reflux, add sulfur 23.2g in batches, along with the addition of sulfur, the reflux temperature is higher and higher, as the reaction proceeds, the color of the reaction solution deepens to purple red, and then continues the heat preservation reaction for 7.5 hours. After the reaction is completed, cool to room temperature, and synthesize The material is slowly added dropwise into hydrochloric acid composed of 50g of 30% hydrochloric acid and 160g of water, and the reaction solution gradually becomes a brownish-yellow turbid liquid, and the addition is completed in about 1 hour; the layers are left to stand, and the upper organic layer is heated and precipitated to remove benzene to obtain diphenylsulfid...

Embodiment 2

[0021] In a four-neck flask equipped with a condenser, a water separator, a thermometer and a tail gas treatment device (tail gas generated by the absorption reaction of the sodium hydroxide solution), add 200g of benzene and 142.8g of ferric chloride, heat up to 50°C, and Under slight reflux, add sulfur 23.2g in batches, along with the addition of sulfur, the reflux temperature is getting higher and higher, as the reaction proceeds, the color of the reaction solution is deepened to purple red, and then the insulation reaction is continued for 6 hours. After the reaction is completed, it is cooled to room temperature, and the The synthetic material is slowly added dropwise to dilute hydrochloric acid composed of 50g of 30% hydrochloric acid and 160g of water, the reaction solution gradually turns into a brownish-yellow turbid solution, and the addition is completed in about 1 hour; standing for stratification, the upper organic layer is heated and precipitated to remove benzene ...

Embodiment 3

[0024] In a four-necked flask equipped with a condenser, a water separator, a thermometer and a tail gas treatment device (tail gas generated by the absorption reaction of the sodium hydroxide solution), add 200g of benzene and 97g of aluminum trichloride, heat up to 70°C, and Under reflux, add sulfur 23.2g in batches, along with the adding of sulfur, reflux temperature is more and more higher, along with reaction, reaction solution color is deepened to purple red, then continue insulation reaction 7.5 hours, then 30% in pickling reaction bottle Dilute hydrochloric acid composed of 50g of hydrochloric acid and 250g of water, slowly add the above-mentioned synthetic material dropwise, the reaction solution gradually turns into a brownish-yellow turbid solution, and the addition is completed in about 1.0h; let stand to separate layers, and then add water to wash until the water layer is neutral.

[0025] In this embodiment, 60.7 g of the product was finally obtained, with a conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com