Synthetic method of imidazole acidic ionic liquid

A technology of acidic ionic liquid and synthesis method, which is applied in the field of chemistry, can solve the problems of easy decomposition, unstable water and air, etc., and achieve the effects of easy separation, pollution avoidance and high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

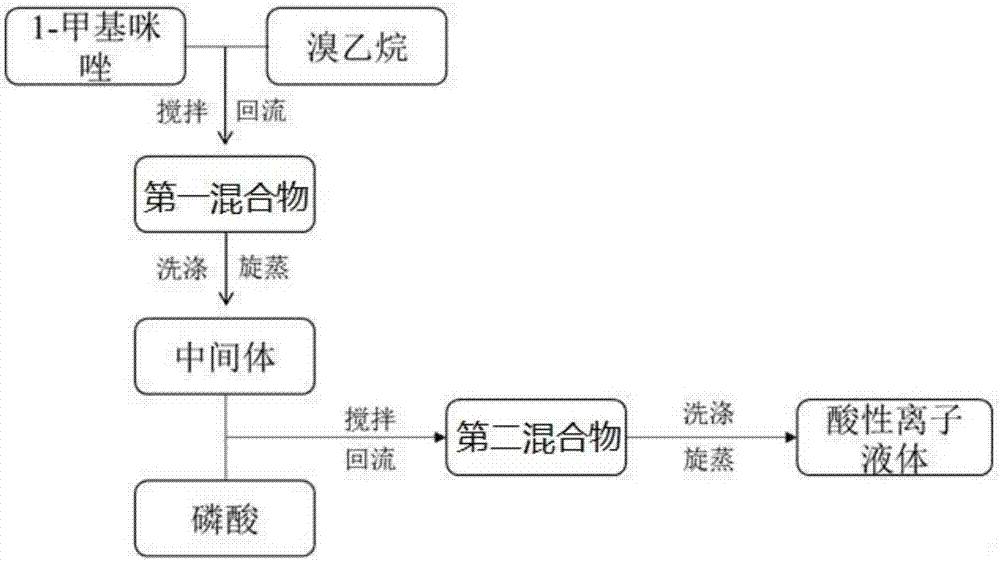

[0023] A kind of synthetic method of imidazole acidic ionic liquid, comprises the following steps:

[0024] (1) Weigh 1-methylimidazole and ethyl bromide at a molar ratio of 1:1.2, then add 1-methylimidazole into a three-necked flask with stirring and condensing and reflux, heat to 75°C, and stir under the condition of ( Add bromoethane dropwise into the three-necked flask at 500~800rpm), keep the temperature at 75°C and stir and reflux for 12h after the dropwise addition is completed for 10~60min to obtain the first mixture, wash the first mixture with ethyl acetate three times, after washing Put it into a vacuum drying oven to dry at 80°C and 0.09MPa for 12 hours to obtain the intermediate;

[0025] (2) Weigh the intermediate obtained in step (1) and 85% phosphoric acid at a molar ratio of 1:1.1, then add the intermediate to a three-necked flask with stirring and reflux, and put it in an ice-water bath to keep the temperature at 0-5 ℃, under the condition of stirring (500-8...

Embodiment 2

[0028] The imidazole-based acidic ionic liquid synthesized in Example 1 has the advantages of good catalytic performance, easy product separation, easy recovery, reusability and environmental friendliness. For example, the ionic liquid can be used in the synthesis of polyaspartic acid. The specific catalytic usage method can be found in patent CN104788674A. The specific operation steps and experimental results are as follows:

[0029] Weigh 10 g of L-aspartic acid and 20 g of the ionic liquid described in Example 1 into a three-neck flask with stirring and cold water separation, wherein the ionic liquid is used as the reaction medium and catalyst, heat up to 180 ° C, and react for 3 hours to obtain Polysuccinimide solution. Quickly add 100ml of ethanol to the polysuccinimide solution to precipitate the polysuccinimide, filter, and rotate the filtrate at 70° C. for 2 hours to obtain the recovered ionic liquid. The polysuccinimide obtained above is hydrolyzed to polyaspartic ...

Embodiment 3

[0033] A kind of synthetic method of imidazole acidic ionic liquid, comprises the following steps:

[0034] (1) Weigh 1-methylimidazole and ethyl bromide at a molar ratio of 1:1.1, then add 1-methylimidazole into a three-necked flask with stirring and condensing and reflux, heat to 65°C, and stir under the condition of ( Add bromoethane dropwise into the three-necked flask at 500rpm), keep the temperature at 65°C and stir and reflux for 9h after the dropwise addition is completed for 60 minutes to obtain the first mixture, wash the first mixture twice with ethyl acetate, and put it into vacuum drying after washing Oven drying at 80°C and vacuum drying at 0.09MPa for 10 hours to obtain the intermediate;

[0035] (2) Weigh the intermediate obtained in step (1) and 85% phosphoric acid at a molar ratio of 1:1.5, then add the intermediate to a three-necked flask with stirring and reflux, and put it in an ice-water bath to keep the temperature at 0-5 ℃, under the condition of stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com