Printed circuit board character marking ink composition and circuit board

A printed circuit board and ink composition technology, which is applied to printed circuit components, ink, circuit inspection/recognition, etc., can solve the problems of complex process, low efficiency, and inability to fundamentally eliminate easy color variation, and achieve good attachment Concentrates and prevents the effect of heterochromia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

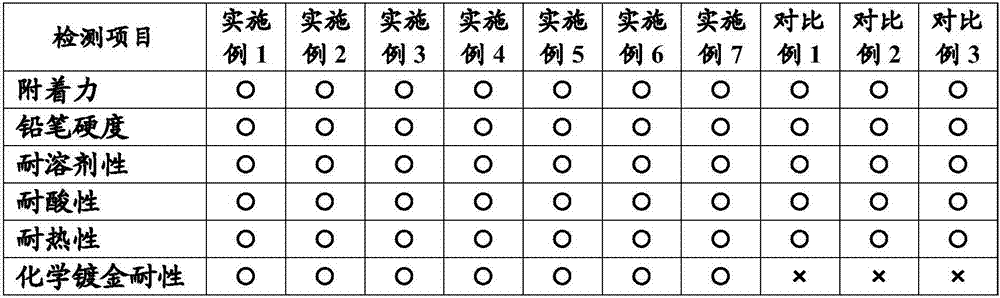

Examples

Embodiment

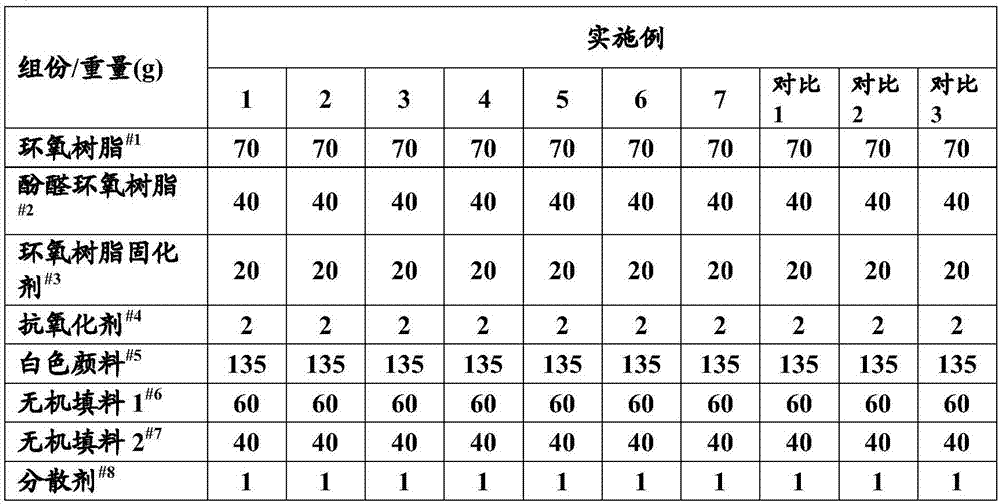

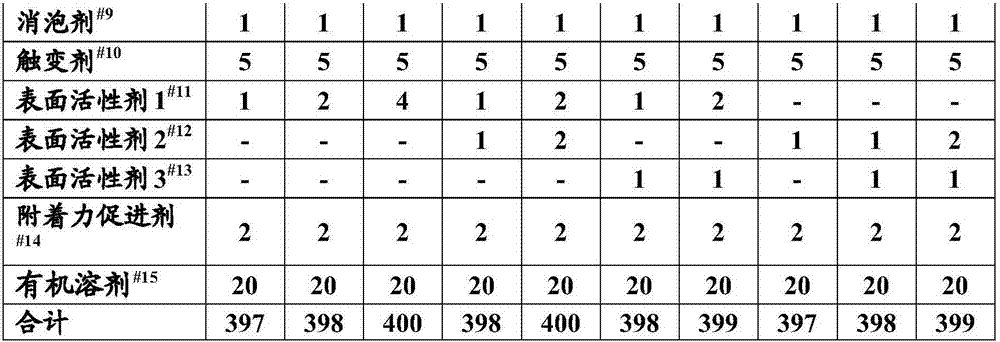

[0053] Mix the components shown in Table 1 according to the ratio (unit: gram) shown in Table 1, disperse at high speed for 10 minutes with a disperser, and then grind with a three-roll mill to obtain a printed circuit with a particle size of less than 20 microns Plate character marking ink composition.

[0054] Table 1:

[0055]

[0056]

[0057] #1: E51 purchased from Kunshan Nanya Electronics Company;

[0058] #2: Purchased from Shandong Shengquan phenolic epoxy resin SQPN-051;

[0059] #3: Superfine melamine purchased from Nanjing Meikai Company;

[0060] #4: Antioxidant Irganox1010 purchased from BASF, Germany;

[0061] #5: Titanium dioxide R930 purchased from Ishihara, Japan;

[0062] #6: Superfine talcum powder purchased from Guangxi Guihua brand;

[0063] #7: A1 precipitated barium sulfate purchased from Guangzhou Jimei Company;

[0064] #8: dispersant dispersant dispersant-111 purchased from German BYK chemical company;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com