Antifouling coating, and application thereof in antifouling of nuclear power station cooling seawater circulating pipeline

A technology of antifouling coatings and solvents, applied in antifouling/underwater coatings, rosin coatings, rubber derivative coatings, etc., can solve the problem of long-term antifouling coatings without nuclear power plant cooling seawater circulation pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 antifouling paint preparation

[0023] Table 1 Long-term antifouling paint ingredients

[0024]

[0025]

[0026] Please add the recipes for the two test paints.

[0027] Preparation:

[0028] The solvent is composed of xylene and modified rosin-based polyoxyethylene liquid. First, mix liquid rosin resin, chlorinated rubber resin liquid, iron red, nano-calcium carbonate, cuprous oxide, titanium dioxide and some solvents, disperse evenly, and then grind them in a grinder until the fineness is below 40 μm to become a pre-scouring pulp; Put the slurry in a clean stirring tank, add dispersing aids, defoamers, dust-proofing aids and the remaining solvent in sequence while stirring, mix evenly and stir until the fineness is below 40 μm; filter and pack.

Embodiment 2

[0029] Embodiment 2 product performance test

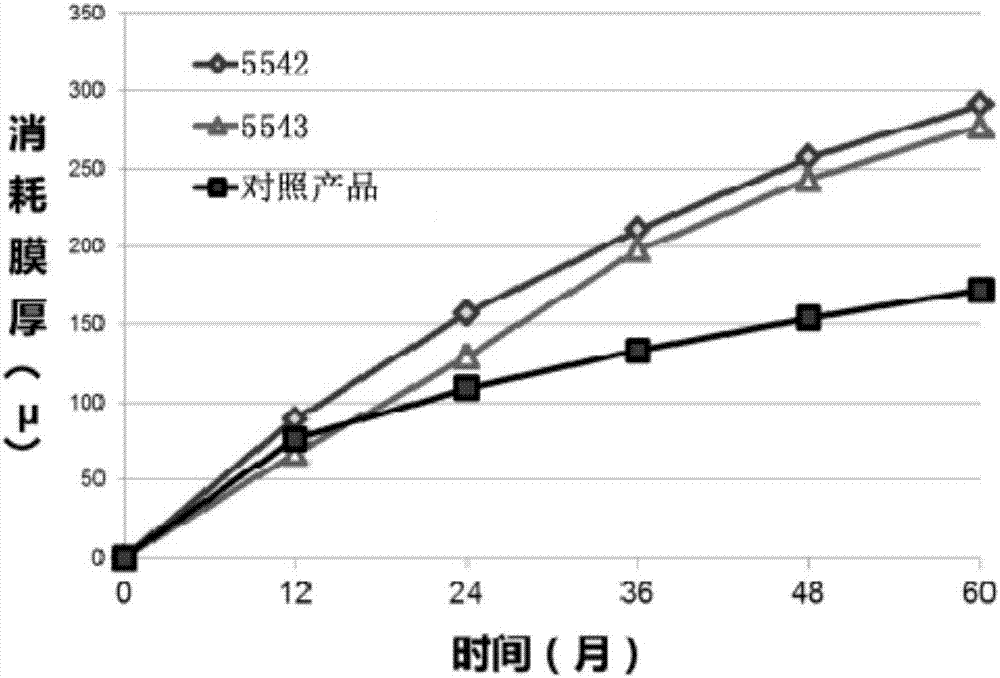

[0030] Performance tests were performed on the antifouling paints of the two formulations in Example 1, and a commercially available tin-free self-polishing antifouling paint was used as a comparison.

[0031] Refer to GB / T7789-2007 for the dynamic simulation of antifouling performance; refer to GB / T7790-2008 for the cathodic disbondment test of the coating in seawater; refer to GB / T5370-2007 for the shallow sea immersion of antifouling paint coatings; soak in tap water at 40°C 4 months coating. The cathodic stripping test after 4200h seawater immersion and 4200h seawater immersion of the antifouling coating is carried out according to the corresponding standard of Norwegian NORSOK M501.

[0032] Performance test results:

[0033] 1. Seawater soaking performance test

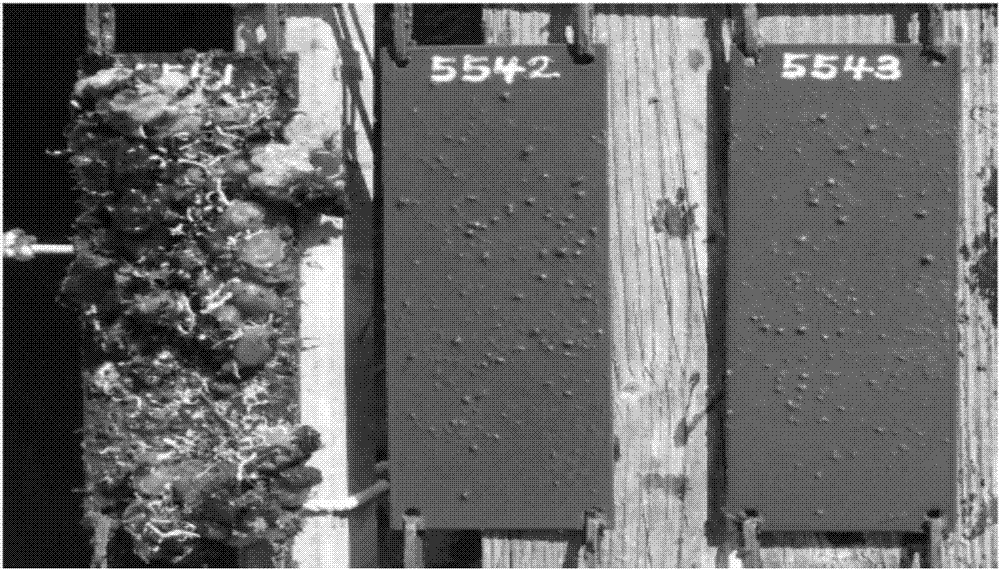

[0034] Soaked in a sea area for 62 months, see the results figure 1 , the far left is the conventional control product, it can be seen that the marine organisms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com