High thermal-conduction nanometer carbon composite material and preparation method thereof

A composite material and nanocarbon technology, applied in the field of material science, can solve the problems of complex preparation process, improved thermal conductivity, poor controllability, etc., and achieve the effect of simple and controllable preparation process, high flexibility, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] An embodiment of one aspect of the present invention provides a method for preparing a high thermal conductivity nano-carbon composite material, comprising:

[0045] Provide aggregates formed by aggregation of multiple carbon nanotubes,

[0046] Providing a graphene oxide dispersion, and incorporating the graphene oxide dispersion into the aggregate to form a carbon nanotube / graphene composite precursor;

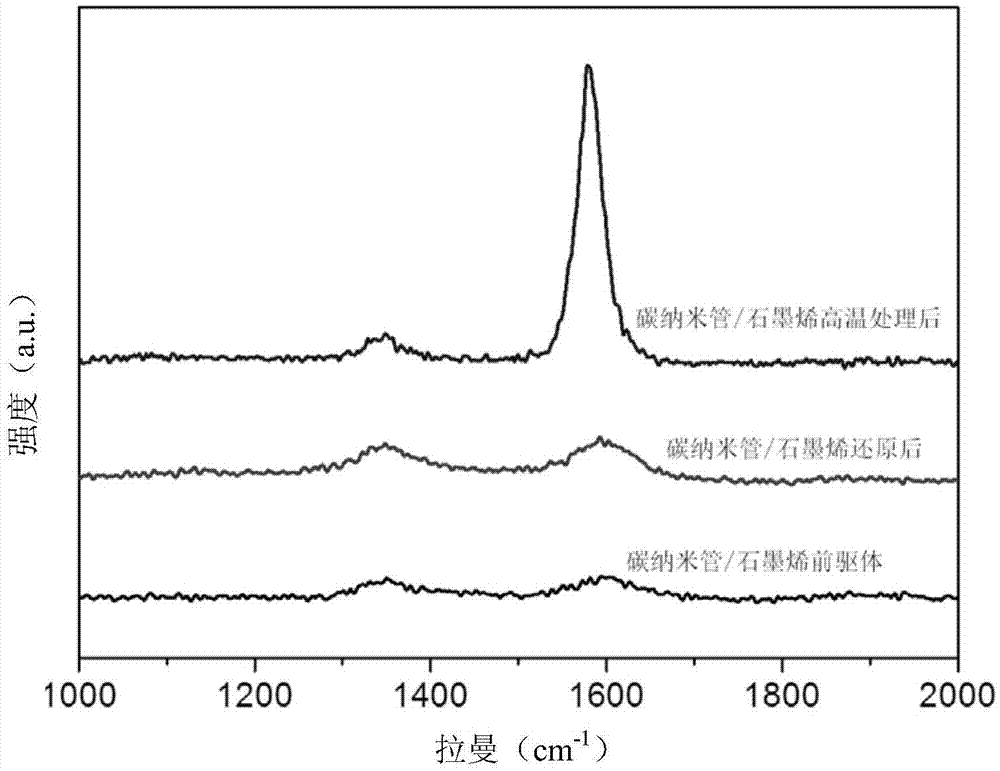

[0047] The carbon nanotube / graphene composite precursor is placed in a reducing atmosphere and heat-treated at 200-500° C. (preferably 300-350° C.) for more than 15 minutes (preferably more than 30 minutes), and then transferred to a protective atmosphere and Heat treatment at 1500-3000° C. (preferably 2000-3000° C.) for more than 15 minutes.

[0048] More preferably, the concentration of the graphene oxide solution is 0.1-3 mg / ml.

[0049] More preferably, the radial dimension of the graphene oxide is 10nm-1mm, and the thickness is 0.24nm-2nm.

[0050] Further, the ...

Embodiment 1

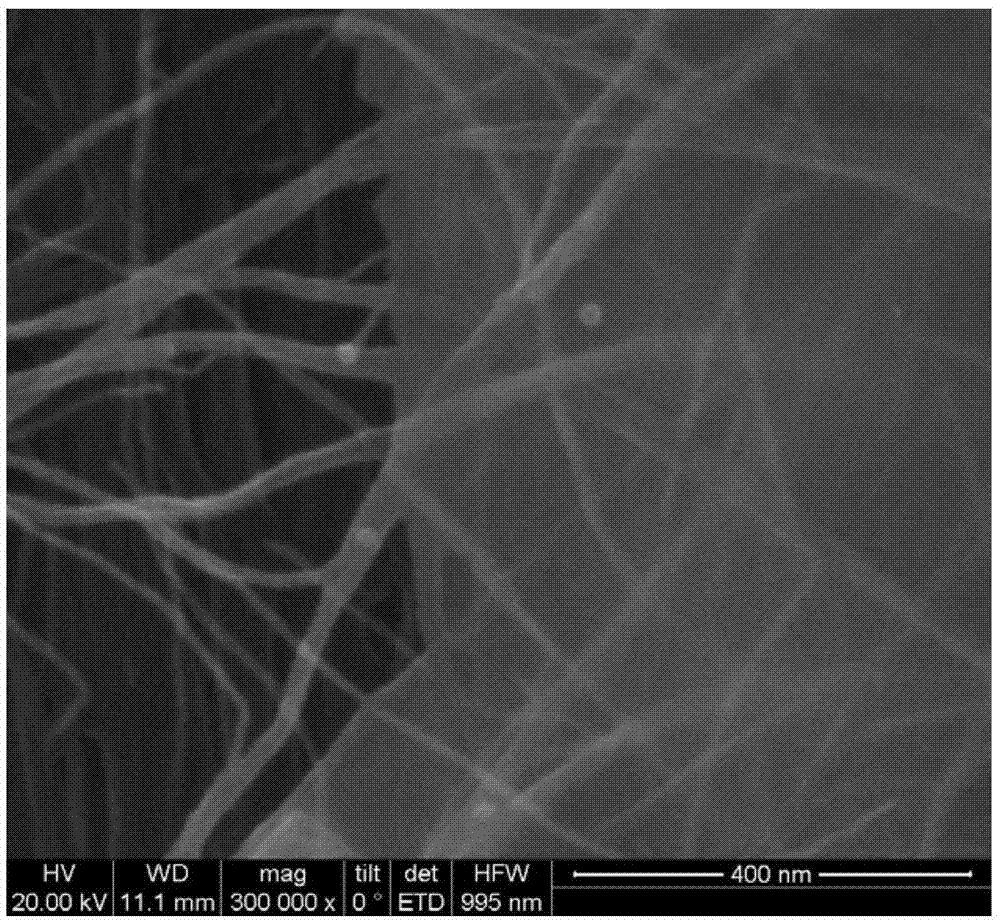

[0082] Using carbon nanotube continuous film (prepared by floating catalytic method), graphene oxide (average radial size above 0.15 μm, number of sheets about 2-5) as raw material, after carbon nanotube / graphene composite film precursor preparation , the reduction process of carbon nanotube / graphene composite film (the first step of heat treatment) and the second step of heat treatment process of carbon nanotube / graphene composite film to achieve the use requirements of high thermal conductivity, high flexibility and high mechanical properties, The process is as follows:

[0083] A. Preparation of carbon nanotube / graphene composite film precursor

[0084] Dissolve 5mg of graphene oxide powder in 10ml of deionized water and ethanol mixture, the volume ratio of deionized water and ethanol is about 1:1, and after magnetic stirring to obtain graphene oxide suspension, ultrasonic treatment, ultrasonic power 30w, ultrasonic After 5 minutes, a graphene oxide solution with a concent...

Embodiment 2

[0092]Adopt continuous film of carbon nanotubes (prepared by array growth drawing film method), graphene oxide (same as embodiment 1) is raw material, through the preparation of carbon nanotube / graphene composite film precursor, carbon nanotube / graphene composite film The reduction process (the first step of heat treatment) and the second step of heat treatment of carbon nanotube / graphene composite film to meet the requirements of high thermal conductivity, high flexibility and high mechanical properties, the process is as follows:

[0093] A. Preparation of carbon nanotube / graphene composite film precursor

[0094] Dissolve 10mg of graphene oxide powder in 10ml of deionized water and ethanol mixture, the volume ratio of deionized water to ethanol is about 1:1, after magnetic stirring to obtain graphene oxide suspension, ultrasonic treatment, ultrasonic power 30w, ultrasonic After 10 minutes, a graphene oxide solution with a concentration of about 1 mg / ml was obtained.

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com