A start-up method of a hydrocracking unit containing a catalyst with a second type of active center

A hydrocracking and active center technology, applied in hydrocarbon oil cracking, petroleum industry, etc., can solve problems such as increased material consumption, increased reagent consumption, and catalyst activity damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

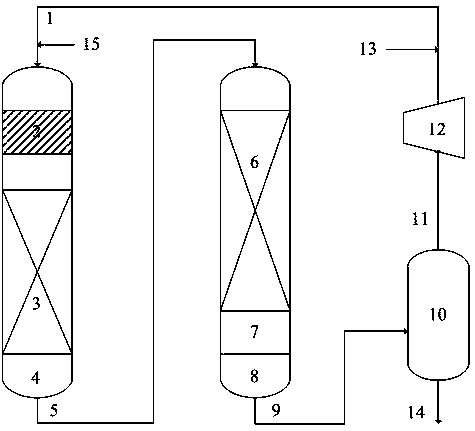

[0045] Such as figure 1 As shown, an embodiment of the hydrogenation catalyst start-up method of the present invention is as follows:

[0046] According to the gas flow direction, the circulating hydrogen 1 passes through the hydrofinishing reactor 4 containing all the external pre-sulfurized hydrogenation protecting agent 2 and the second type of active center hydrotreating catalyst 3 to obtain the effluent 5; The hydrocracking reactor 8 of the cracking catalyst 6 and the hydrocracking post-treatment catalyst 7 , and the effluent 9 enters the high-pressure separator 10 . The gaseous phase 11 discharged from the top passes through the recycle hydrogen compressor 12 and is mixed with make-up hydrogen 13 to obtain recycle hydrogen 1 . After opening up the process flow according to the above steps, gradually increase the inlet temperature of the hydrotreating reactor 4 to 200°C, control the inlet temperature of the lower hydrotreating catalyst bed to 160°C by cooling hydrogen, a...

Embodiment 1

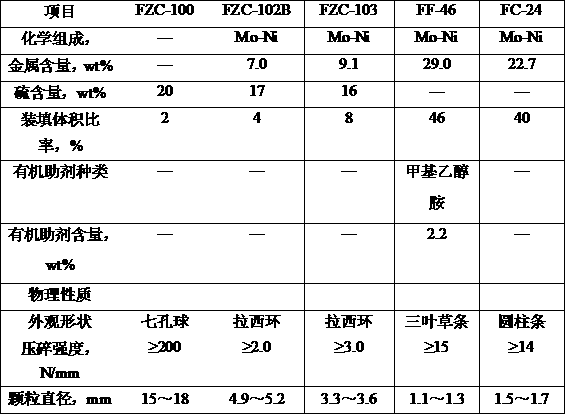

[0048] The properties of the protective agent and catalyst used in Example 1 and Comparative Examples 1 and 2 are listed in Table 1. Both are commercial protective agents and catalysts developed and produced by Fushun Petrochemical Research Institute, wherein Example 1 is the start-up method of the present invention. Using the above-mentioned implementation mode, when formulating the plan, the loading and loading capacity of the pre-vulcanized protective agent outside the device should be adjusted. Sulfur content, so that its excess sulfur content reaches more than 25% of the theoretical sulfur demand of the second-type active center catalyst. Comparative Example 1 is a conventional dry start-up process, and Comparative Example 2 is a conventional wet start-up process.

[0049] Table 1 The main physicochemical properties of the catalysts.

[0050]

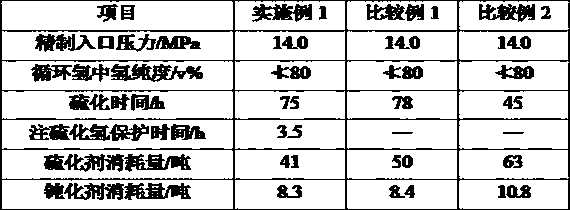

[0051] Example 1

[0052]After the hydrogen airtightness of the hydrocracking unit is qualified, the inlet pressure of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com