Two-step method for preparing high-purity titanium

A high-purity, one-step technology, applied in the field of high-purity titanium preparation from molten salt, can solve the problems of long process, low product quality, high energy consumption, etc., and achieve the effect of improving quality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

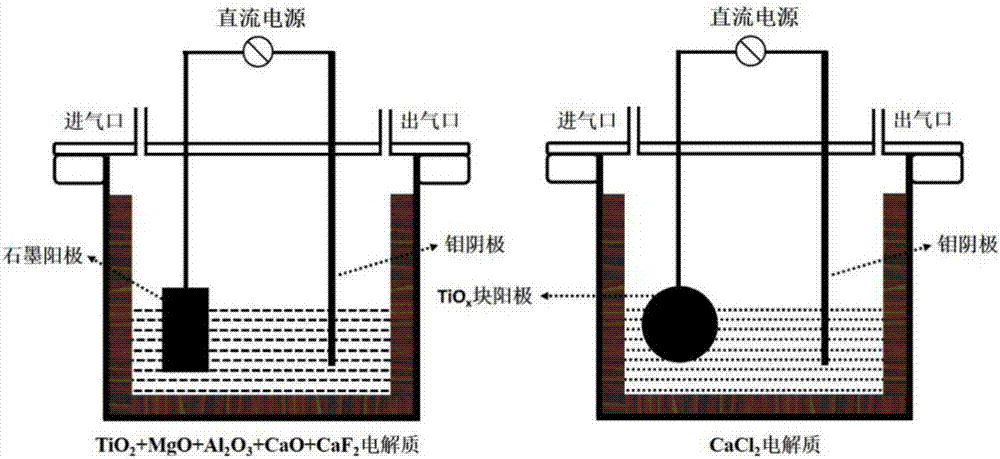

Embodiment 1

[0025] Mixed oxide TiO 2 +MgO+Al 2 o 3 +CaO and CaF with a mass fraction of 10% 2 additives as electrolytes, where TiO 2 The mass percentage is 20%. Mix the electrolyte evenly and place it at the bottom of the reaction vessel, insert the graphite anode and the metal molybdenum cathode, cover the reaction device and perform sealing treatment. After evacuating, the inert protective atmosphere of argon is introduced, and argon protection is maintained at a certain flow rate. After the atmosphere in the reaction device is stabilized, the reaction device is heated to 1500 ° C at a rate of 300 ° C / hour and kept for 3 hours, so that The electrolyte is in a uniform melting state, ensuring uniform temperature distribution in the reaction device. The graphite anode was then slowly inserted into the molten electrolyte with a cathodic current density of 0.5 A / cm 2 Constant current electrolysis for 2 hours. After the electrolysis is completed, the cathode product is collected, was...

Embodiment 2

[0028] Mixed oxide TiO 2 +MgO+Al 2 o 3 +CaO and 10% LiF additive as the electrolyte, in which TiO 2 The mass percentage is 50%. Mix the electrolyte evenly and place it at the bottom of the reaction vessel, insert the SnO 2 An inert anode and a metal nickel cathode are covered with a reaction device cover and sealed. After evacuating, argon gas is introduced into the inert protective atmosphere, and argon protection is maintained at a certain flow rate. After the atmosphere in the reaction device is stabilized, the reaction device is heated to 1700°C at a rate of 300°C / hour and kept for 3 hours, so that The electrolyte is in a uniform melting state, ensuring uniform temperature distribution in the reaction device. The graphite anode was then slowly inserted into the molten electrolyte with a cathodic current density of 0.5 A / cm 2 Constant current electrolysis for 2 hours. After the electrolysis is completed, the cathode product is collected, washed repeatedly with hydroc...

Embodiment 3

[0031] Mixed oxide TiO 2 +MgO+Al 2 o 3 +CaO and 5% LiF+NaF (50:50% by mass) additives as electrolytes, in which TiO 2 The mass percentage is 30%. Mix the electrolyte evenly and place it at the bottom of the reaction vessel, insert the graphite anode and the metal titanium cathode, cover the reaction device and perform sealing treatment. After evacuating, the inert protective atmosphere argon is introduced, and argon protection is maintained at a certain flow rate. After the atmosphere in the reaction device is stable, the reaction device is heated to 1600 ° C at a rate of 300 ° C / hour and kept for 3 hours, so that The electrolyte is in a uniform melting state, ensuring uniform temperature distribution in the reaction device. Then the graphite anode was slowly inserted into the molten electrolyte, and a 5V direct current was applied for electrolysis for 2 hours. After the electrolysis is completed, the cathode product is collected, washed repeatedly with hydrochloric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com