Quantitative calibration system of X-ray imaging plate

A calibration system, X-ray technology, applied in the field of quantitative calibration system of X-ray imaging plate, can solve the problems of blocking high-energy X-rays, calibration error, and need to be reduced, and achieve the effect of important application prospects and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

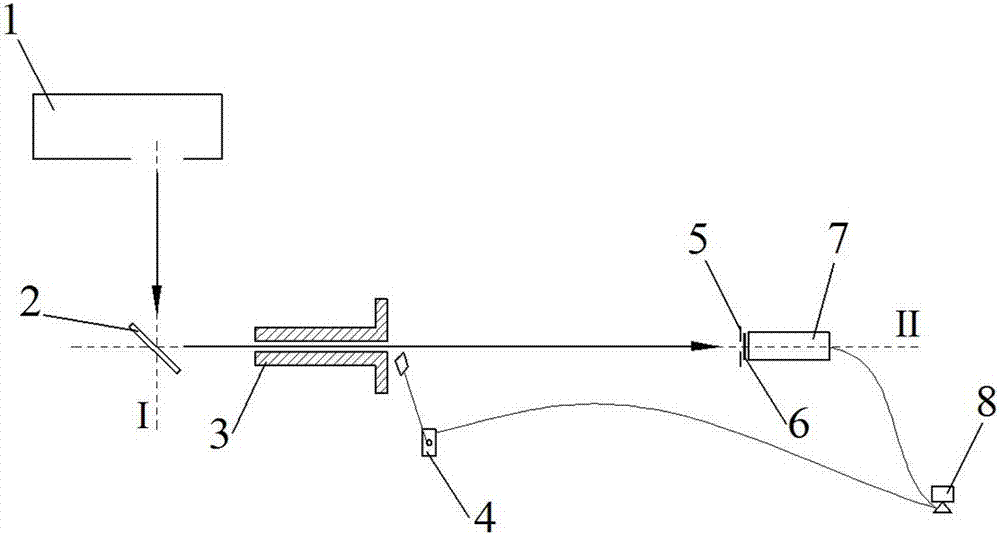

[0028] In this embodiment, the voltage value of the tungsten X-ray tube 1 is twice the atomic number 29 of the metal copper in the metal foil 2, and the voltage of the tungsten X-ray tube 1 is 58 kV; the diameter of the metal foil 2 is 47mm , the purity of the metal in the metal foil 2 is equal to 99.5%; the metal in the metal foil 2 is made of copper; the block of the non-standard shutter 4 is made of lead material with a thickness of 5 mm; ° / s; the diameter of the limiting hole 5 is 3 mm, and the thickness is equal to 5 mm; the distance between the limiting hole 5 and the metal foil 2 is 90 mm. In this embodiment, the linear response range of the X-ray imaging plate is quantitatively calibrated, and the X-ray imaging plate 6 used is an MS-type imaging plate.

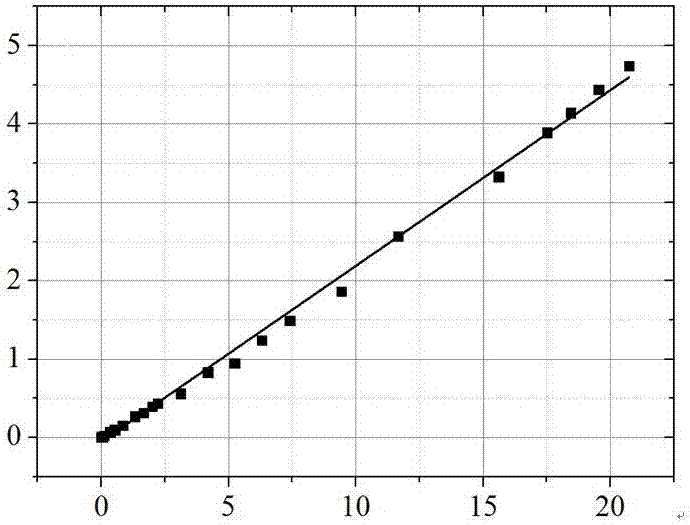

[0029] Due to the obvious differences in the production of X-ray imaging plates and the significant difference in the process of scanning and reading data, the quantitative application of X-ray imaging plates cannot di...

Embodiment 2

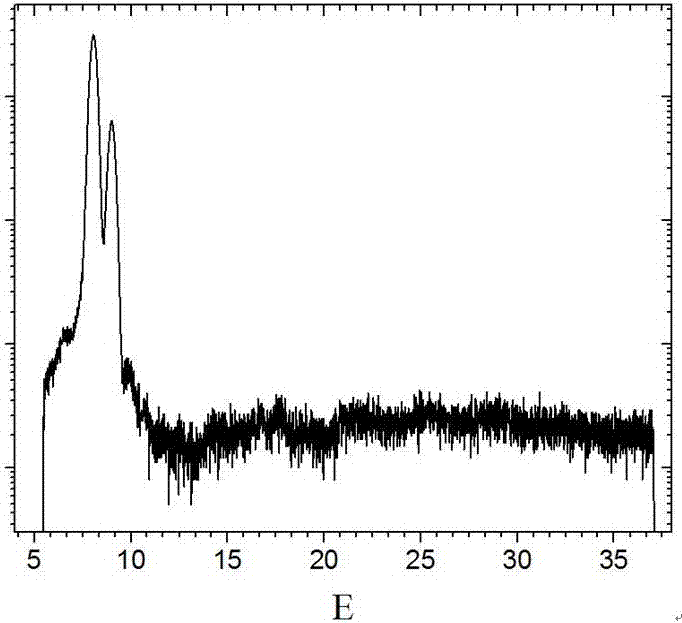

[0036] The voltage value of the tungsten X-ray tube 1 is twice the atomic number 26 of the metal iron in the metal foil 2, and the voltage is 52 kV; the diameter of the metal foil 2 is 55mm, and the purity of the metal in the metal foil 2 is equal to 99.7%; the metal foil The metal in 2 is iron; the block of non-standard shutter 4 is lead material with a thickness of 7mm; the rotating speed of the lever controlling the movement of the lead block in non-standard shutter 4 is 55° / s; the diameter of limiting hole 5 is 4mm, and the thickness is equal to 8mm; the distance between the hole 5 and the metal foil 2 is 105mm. In this embodiment, the linear response coefficient of the X-ray imaging plate is quantitatively calibrated, and the X-ray imaging plate 6 used is an SR imaging plate. The lower limit of the spectral purity of the calibration light source obtained in this embodiment is 78%, which is 13% higher than the previously reported 65%. In addition, due to the use of the no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com