Spiral step fin tower for purifying VOCs waste gas

A spiral and stepped technology, applied in the field of volatile organic compound waste gas treatment, can solve the problems of failing to purify VOCs waste gas, and the electric heating purification filter element has no solution, so as to increase the time of contact mass transfer, reduce energy consumption, and improve The effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

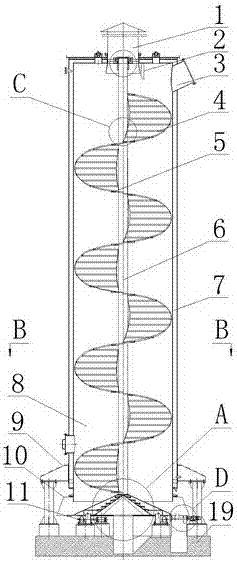

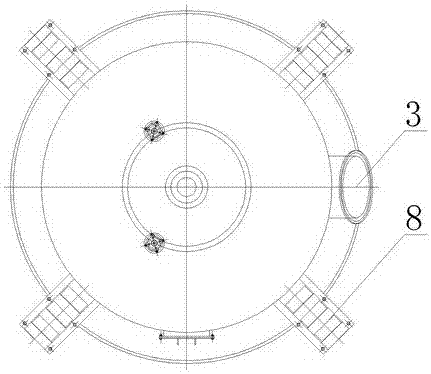

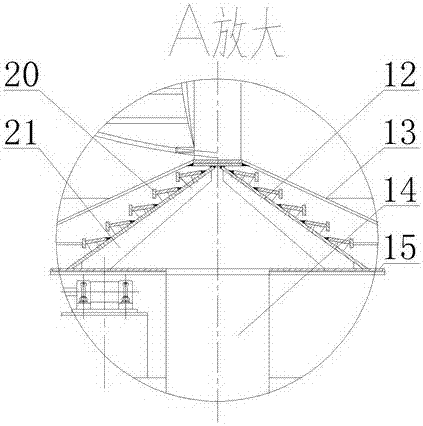

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a spiral stepped fin tower for purifying VOCs exhaust gas is characterized in that it includes a tower body assembly 8 , a slag discharge turntable assembly 10 , an idler assembly 11 , and a platform 19 .

[0027] The tower body assembly 8 includes an exhaust tube 1, a plow rake 2, an adsorbent inlet 3, a tower body 7, a support column 9, and a bearing seat 18. The exhaust tube 1 is connected to the tower body 7, and the purified exhaust gas flows from The exhaust pipe 1 is discharged into the atmosphere, the plow rake 2 is installed on the top of the tower body 7, and the adsorbent filler entering from the adsorbent inlet 3 is evenly spread on the rotating spiral stepped fins 4, and the support column 9 Connect with the tower body 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com