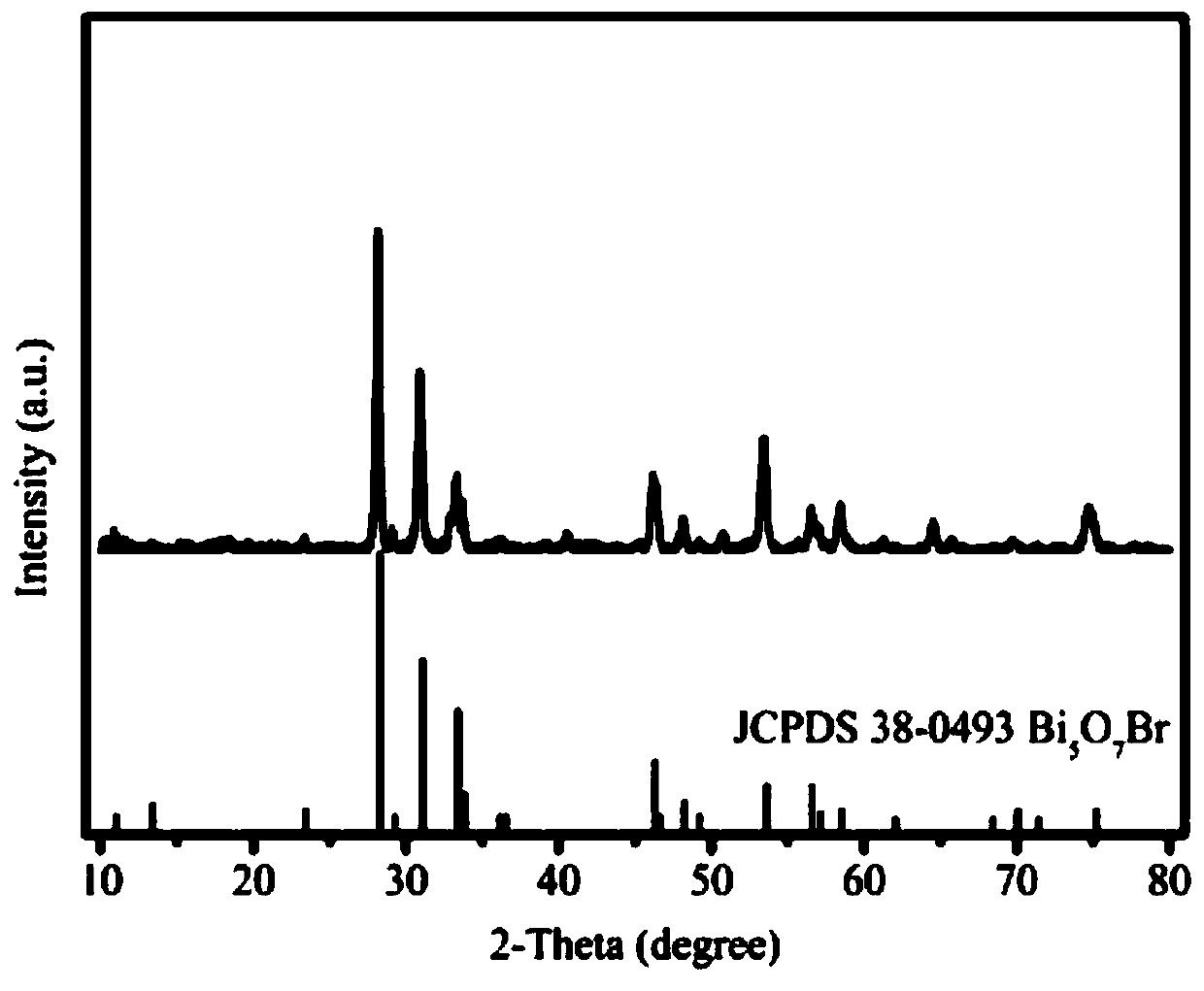

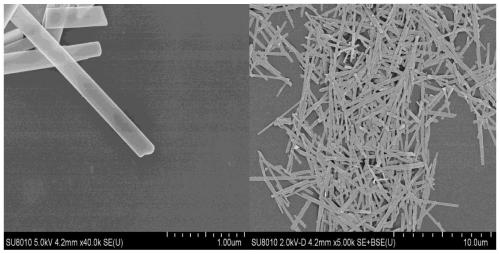

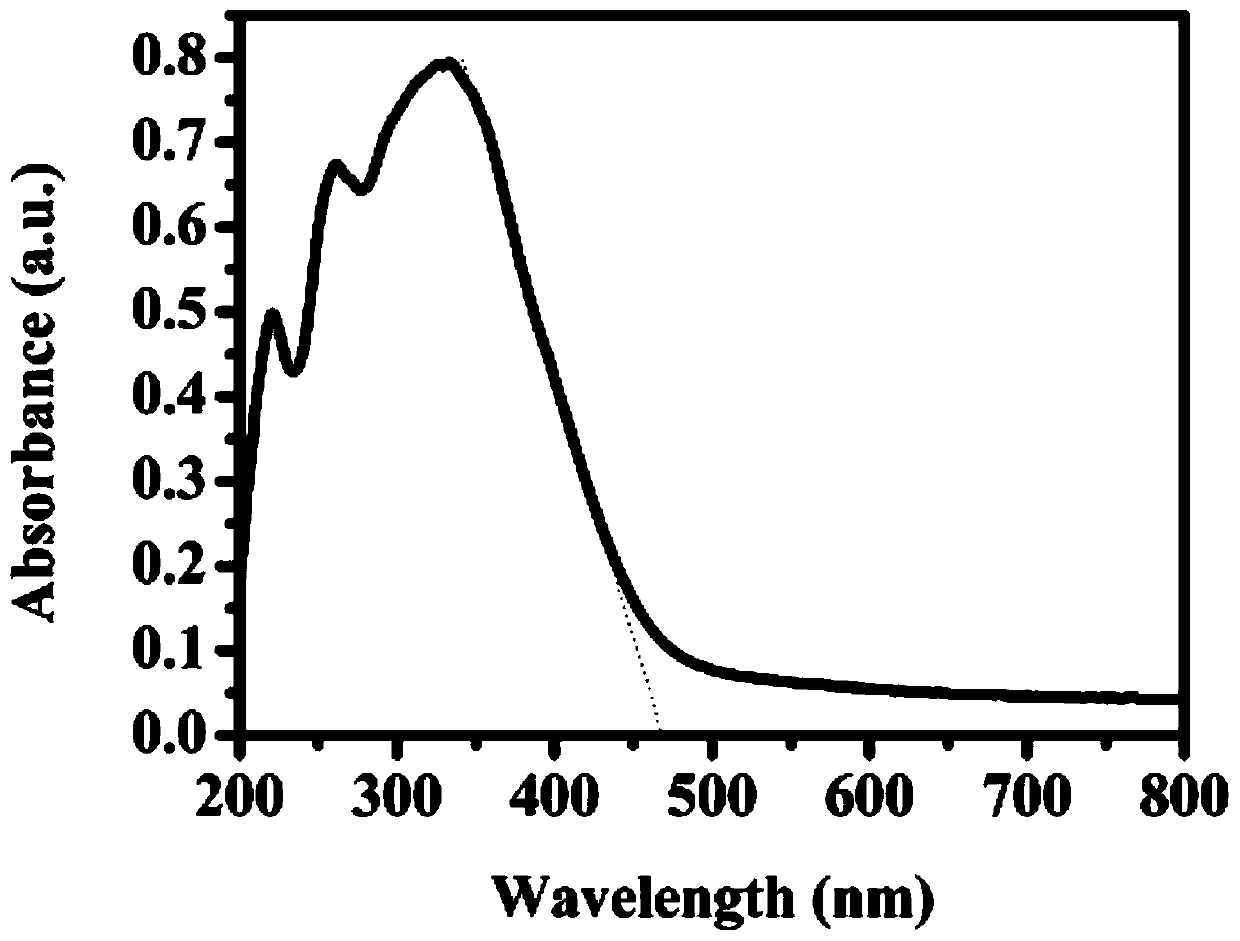

A kind of preparation method of bi5o7br nanometer photocatalytic material with ribbon structure

A ribbon structure and catalytic material technology, which is applied in the field of nanomaterials and solar photocatalysis, can solve the problems of product impurity, irregular and uniform microscopic morphology, and achieve the effect of regular and uniform morphology and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Bi with a ribbon structure 5 o 7 The preparation method of Br nanometer photocatalytic material, its step is as follows:

[0037] (1) Weigh 2mmol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) be dissolved in 25ml of anhydrous methanol, constantly stir to obtain solution A after bismuth nitrate dissolves completely;

[0038] (2) Weigh 2mmol CTAB and 0.6g polyvinylpyrrolidone and dissolve them in 25ml of anhydrous methanol, stir well to obtain solution B;

[0039] (3) Add solution A to solution B, stir well to obtain solution C, then slowly add 1mol / L sodium hydroxide solution to solution C, adjust pH=13.10 to obtain solution D;

[0040] (4) Transfer the solution D to a polytetrafluoroethylene-lined reactor, and react at a constant temperature at 180°C for 5 hours;

[0041] (5) After the reaction, the obtained precipitate was first washed 3 times with deionized water, and then washed 4 times with absolute ethanol, and then the product was dried in an oven at 60...

Embodiment 2

[0043] Bi with a ribbon structure 5 o 7 The preparation method of Br nanometer photocatalytic material, its step is as follows:

[0044] (1) Weigh 2mmol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) be dissolved in 30ml dehydrated alcohol, constantly stir to obtain solution A after bismuth nitrate dissolves completely;

[0045] (2) Weigh 2mmol CTAB and 0.8g polyvinylpyrrolidone and dissolve them in 30ml of absolute ethanol, stir well to obtain solution B;

[0046] (3) Add solution A to solution B, stir well to obtain solution C, then slowly add 2 mol / L sodium hydroxide solution to solution C, adjust pH=12.91 to obtain solution D;

[0047] (4) Transfer the solution D to a polytetrafluoroethylene-lined reactor, and react at a constant temperature of 180° C. for 24 hours;

[0048] (5) After the reaction, the obtained precipitate was first washed 5 times with deionized water, then washed 3 times with absolute ethanol, and then the product was dried in a 60°C oven to obt...

Embodiment 3

[0050] Bi with a ribbon structure 5 o 7 The preparation method of Br nanometer photocatalytic material, its step is as follows:

[0051] (1) Weigh 2mmol bismuth sulfate (Bi 2 (SO 4 ) 3 ) was dissolved in 40ml of anhydrous methanol, and was continuously stirred to obtain solution A after bismuth sulfate was completely dissolved;

[0052] (2) Weigh 2mmol potassium bromide and 1.2g polyvinylpyrrolidone and dissolve them in 40ml of anhydrous methanol, stir to obtain solution B;

[0053] (3) Add solution A to solution B, stir well to obtain solution C, then slowly add 1 mol / L potassium hydroxide solution to solution C, adjust pH=13.21 to obtain solution D;

[0054] (4) Transfer the solution D to a polytetrafluoroethylene-lined reactor and react at a constant temperature of 150°C for 12 hours;

[0055] (5) After the reaction, the obtained precipitate was first washed 3 times with deionized water, then washed 3 times with absolute ethanol, and then the product was dried in an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com