Method for synthesizing carbonized MOFs (metal organic frameworks) by solvothermal method

A solvothermal method and a solvothermal reaction technology are applied in the field of solvothermal synthesis of carbonized MOFs, which can solve the problems of high energy consumption, high requirements on synthesis equipment and complicated operation, and achieve low reaction temperature, controllability and adjustment degree. , The effect of material appearance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

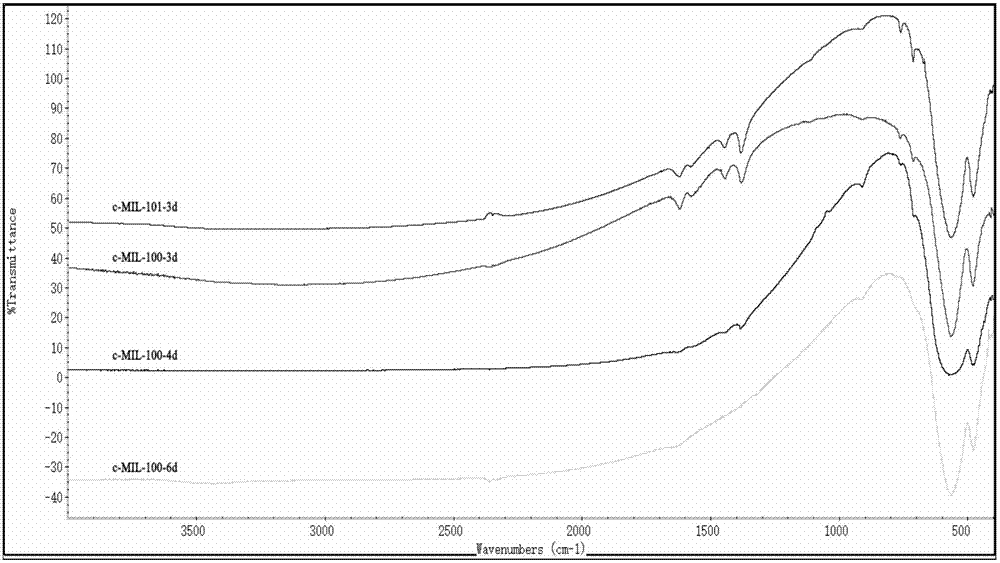

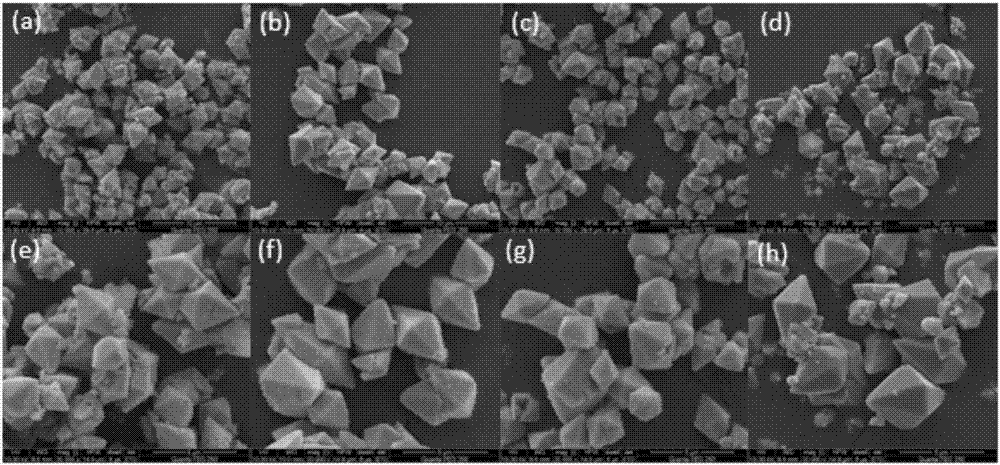

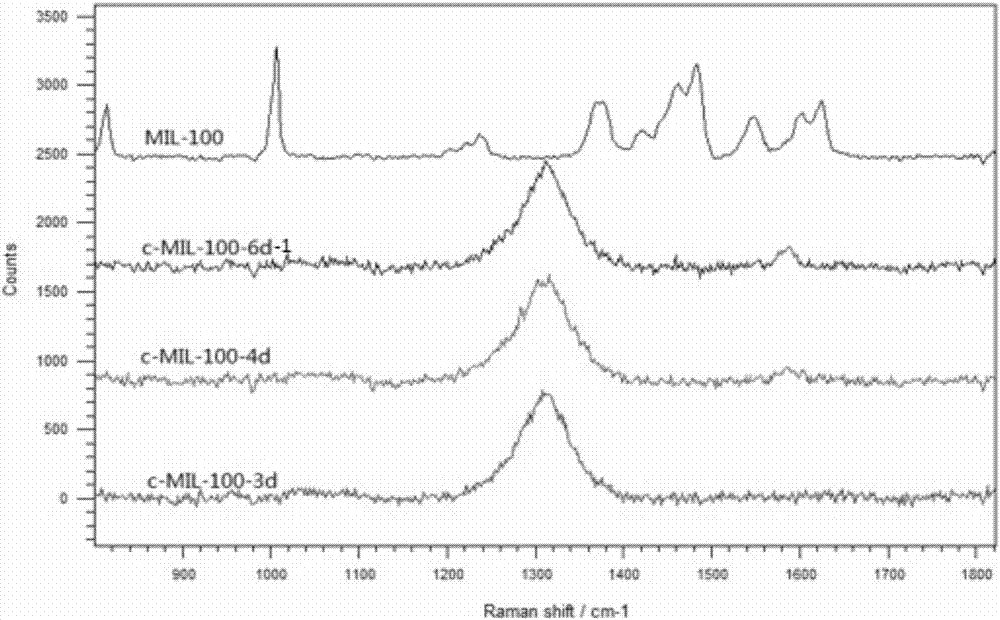

[0026] Weigh 5.4059gFeCl 3 ·6H 2 O and 1.6614g H 2 BTC was dissolved in 80mL of methanol, and then 2mL of hydrofluoric acid and 1mL of nitric acid were added. 350W ultrasonic dispersion for 30min, after the end of ultrasonication, transfer the mixed solution to a 100mL reaction kettle, and carry out hydrothermal reaction at 220°C for 72h, the obtained black precipitate was washed with absolute ethanol and deionized water, filtered, and heated at 60°C After drying, carbonized MIL-101 (c-MIL-101-3d) is obtained.

Embodiment 2

[0028] Weigh 2.0272g FeCl 3 ·6H 2 O and 0.8307g H 3 BTC was dissolved in 40mL of methanol, and then 0.8mL of hydrofluoric acid and 0.375mL of nitric acid were added. 350W ultrasonic dispersion for 30min, after the end of ultrasonication, transfer the mixed solution to a 50mL reactor, and conduct a hydrothermal reaction at 220°C for 72h, the resulting black precipitate was washed with absolute ethanol and deionized water, filtered, and heated at 60°C After drying, carbonized MIL-100 (c-MIL-100-3d) is obtained.

Embodiment 3

[0030] Weigh 2.0272g FeCl 3 ·6H 2 O and 0.8307g H 3 BTC was dissolved in 40mL of methanol, and then 1.2mL of hydrofluoric acid and 0.375mL of nitric acid were added. 350W ultrasonic dispersion for 30min, after the end of ultrasonication, transfer the mixed solution to a 50mL reactor, and conduct a hydrothermal reaction at 220°C for 96h, the resulting black precipitate was washed with absolute ethanol and deionized water, filtered, and heated at 60°C After drying, carbonized MIL-100 (c-MIL-100-4d) is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com