Preparation method of titanium dioxide nanorod modified carbon cloth enhanced resin matrix composite material

A technology of reinforcing resin base and titanium dioxide, which is applied in the fields of carbon fiber, textile and papermaking, fiber processing, etc., can solve the problems of inability to ensure uniform separation and cumbersome process, and achieve improved tribological performance, overall structural enhancement, and stable braking process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

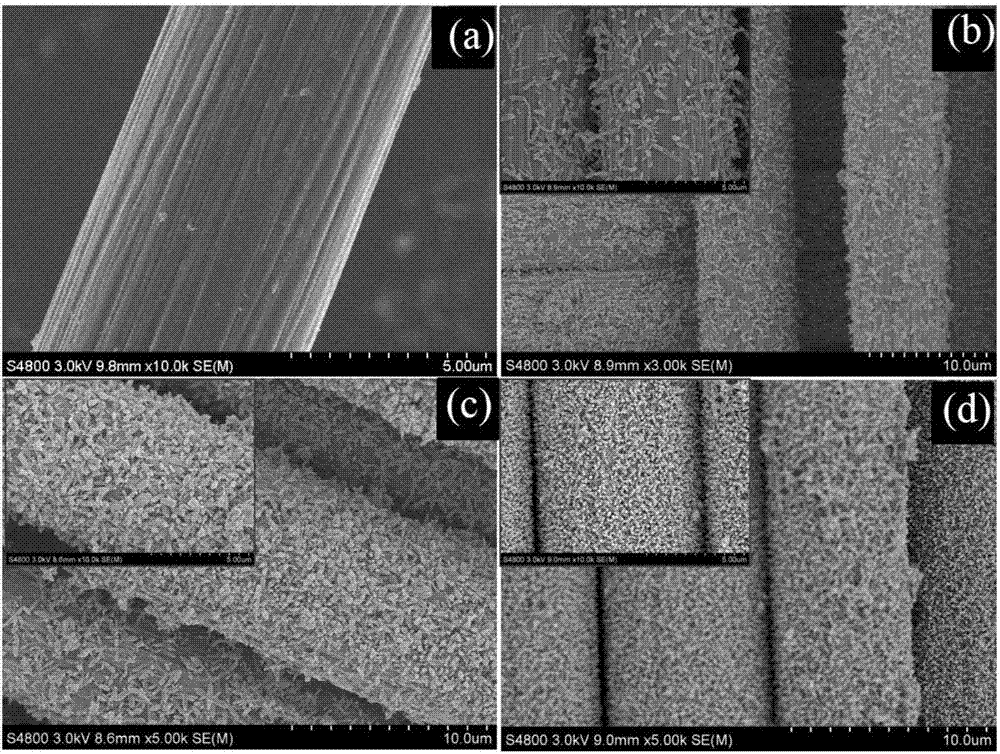

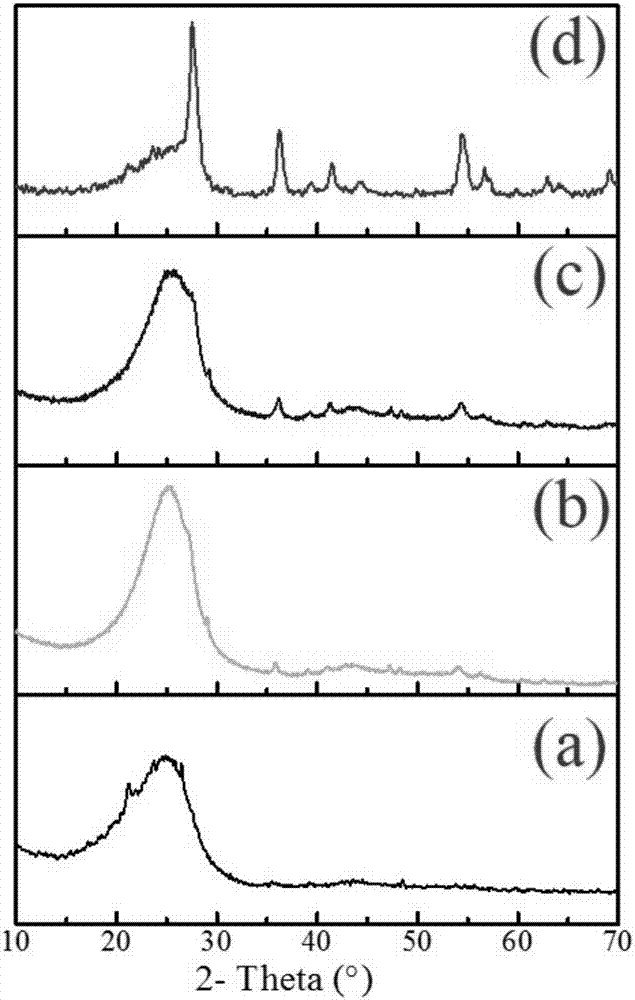

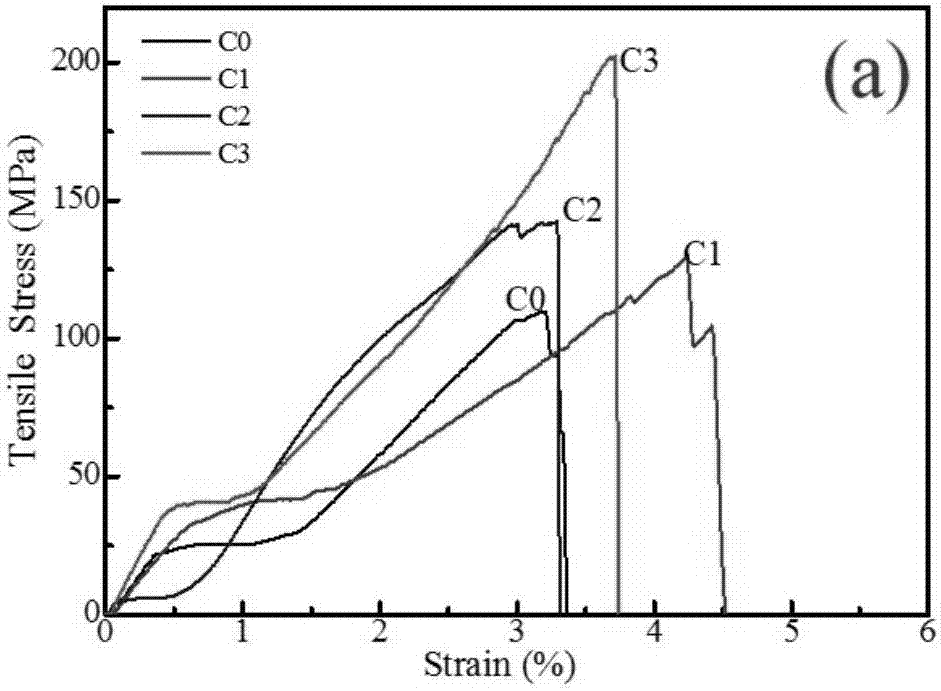

[0032] A preparation method of titanium dioxide nanorod modified carbon cloth reinforced resin-based composite material, comprising the following steps:

[0033] Step 1: Inoculation of TiO on the surface of carbon cloth fiber 2 seed layer.

[0034] In parts by volume, take 100 parts of absolute ethanol in a beaker, add 1-5 parts of concentrated hydrochloric acid dropwise, and stir well. Add 5-20 parts of butyl titanate dropwise into the prepared acidic solution, stir for 30 minutes and then let stand for 1 hour to form TiO 2 Sol. The carbon cloth washed with acetone was soaked in the sol for 5 minutes to inoculate, the inoculation process was repeated 1-5 times, and then dried in an oven at 100°C for 10 minutes to obtain a pretreated carbon cloth.

[0035] Step 2: Hydrothermal growth of TiO 2 Nano stave.

[0036] Arrange the pretreatment carbon in the mixed solution of deionized water: concentrated hydrochloric acid: hydrogen peroxide: butyl titanate = (20-30): (10-20): (...

Embodiment 1

[0041] Step 1: Inoculation of TiO on the surface of carbon cloth fiber 2 seed layer.

[0042] In parts by volume, take 100 parts of absolute ethanol in a beaker, add 1 part of concentrated hydrochloric acid dropwise, and stir well. Add 5 parts of butyl titanate dropwise to the prepared acidic solution, stir for 30 minutes and then let it stand for 1 hour to form TiO 2 Sol. Soak the washed carbon cloth in the sol for 5 minutes for inoculation, repeat the inoculation process once, and then place it in an oven at 100°C for 10 minutes to obtain a pretreated carbon cloth.

[0043] Step 2: Hydrothermal growth of TiO 2 Nano stave.

[0044]Arrange the above carbon in a mixed solution of deionized water: concentrated hydrochloric acid: hydrogen peroxide: butyl titanate = 20:20:1:1, and place it in a homogeneous hydrothermal apparatus for 1 hour of hydrothermal heating at a temperature of 100°C. After the reaction, the carbon cloth was taken out and dried in an oven at 100°C for 5 ...

Embodiment 2

[0048] Step 1: Inoculation of TiO on the surface of carbon cloth fiber 2 seed layer.

[0049] In parts by volume, take 100 parts of absolute ethanol in a beaker, add 2 parts of concentrated hydrochloric acid dropwise, and stir well. Add 10 parts of butyl titanate dropwise to the prepared acidic solution, stir for 30 minutes and then let it stand for 1 hour to form TiO 2 Sol. Soak the washed carbon cloth in the sol for 5 minutes for inoculation, repeat the inoculation process 3 times, and then place it in an oven at 100°C for 10 minutes to obtain a pretreated carbon cloth.

[0050] Step 2: Hydrothermal growth of TiO 2 Nano stave.

[0051] The above carbon was placed in a mixed solution of deionized water: concentrated hydrochloric acid: hydrogen peroxide: butyl titanate = 25:15:1:1, and placed in a homogeneous hydrothermal apparatus for 3 hours, and the hydrothermal temperature was 120°C. After the reaction, the carbon cloth was taken out and dried in an oven at 100°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com