Electrodeposition method for preparing transition metal nano-catalyst and application thereof in electrocatalytic CO2 reduction

A nano-catalyst and transition metal technology, applied in the field of electrocatalyst preparation, can solve the problems of slow deposition rate, morphology change, hindering catalytic performance, etc., and achieve the effect of improving stability, shape stability and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

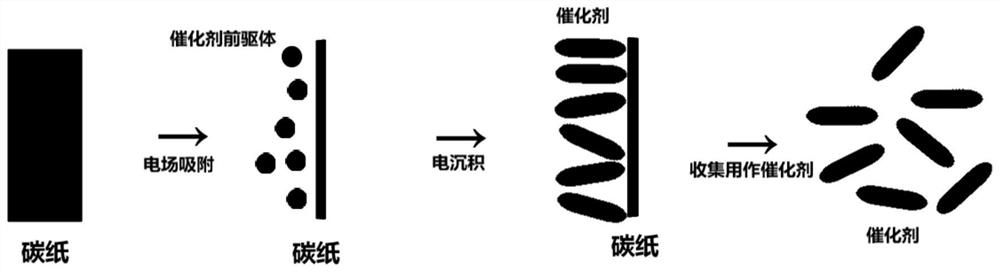

[0045] A method for preparing transition metal nano-catalysts by electrodeposition, the steps are:

[0046] A. Precipitating electrodeposition precursors in solution through metathesis reactions;

[0047] A1. Prepare the electrolyte solution and prepare KHCO with a concentration of 2M 3 ;

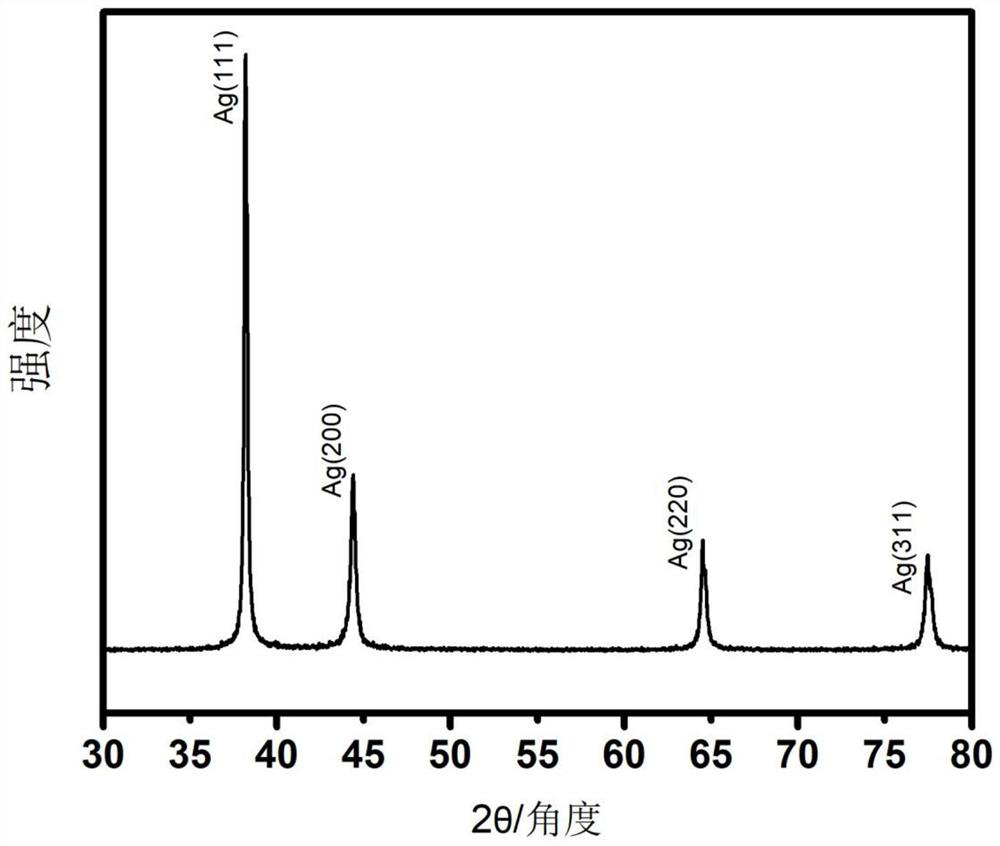

[0048] A2. Weigh 0.1mol AgNO 3 , with 100ml 2M KHCO 3 Mix and react for 30 minutes at a stirring speed of 500rpm; wherein the mixing scheme is KHCO 3 with 100mL 2M AgNO 3 The solution mixes to form Ag 2 CO 3 precipitation;

[0049] A3. Let the precipitation stand still. After collecting the precipitation, wash it fully with deionized water, and place it in an oven at 60 ° C for 1 day to obtain Ag 2 CO 3 Electrodeposition precursors;

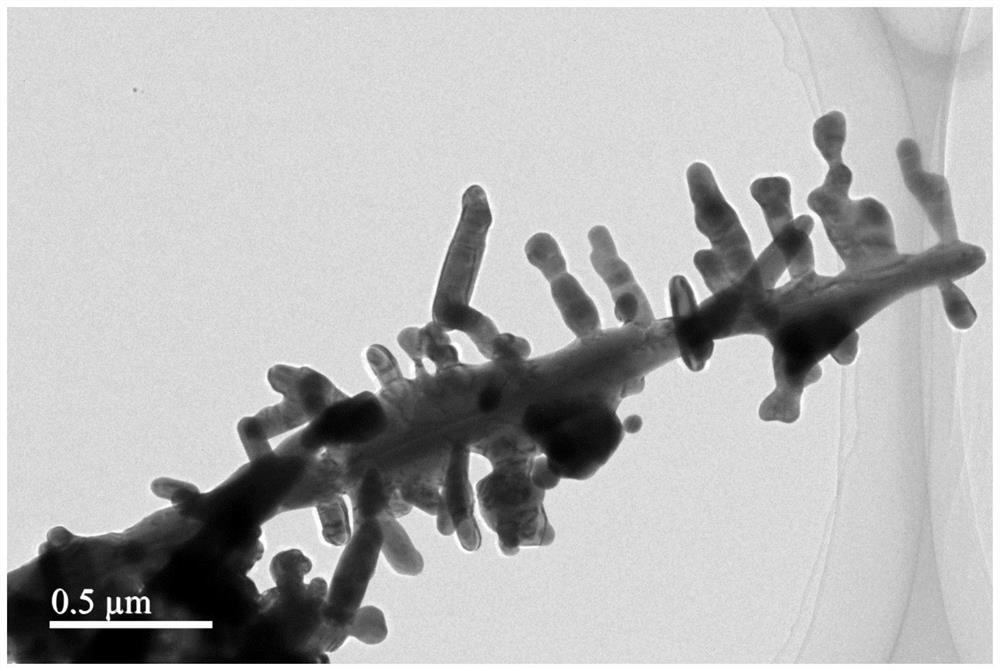

[0050] B. Obtain transition metal nanostructures on the working electrode carrier by electrodeposition, specifically:

[0051] B1. Prepare electrodeposition mixed solution: dissolve 2.5g potassium bicarbonate in 50ml deionized water to form 0.5M KHC...

Embodiment 2

[0061] Similar to Example 1, in this example, the catalyst was synthesized using Scheme 5, and the formed catalyst was characterized by X-ray photoelectron spectroscopy. The results show that the Zn catalyst has abundant valence peaks, which are the peak of Zn-OH, the peak of Zn=O and the peak of Zn2p. Among them, the peak of Zn2p representing Zn element is the highest, indicating that the main component of the catalyst is Zn element, but The presence of oxidation states brings more electronic states to the catalyst.

[0062] There are many examples of transition metal nanomaterials formed from catalyst precursors. The following table shows the morphology and CO of each transition metal catalyst. 2 restore performance.

[0063]

[0064]

[0065] Summary of the examples listed in the above table, catalyst carrier, catalyst precursor quality and treatment method, CO 2 The reduction test methods are all the same as the method adopted in Example 1. CO 2 Restore the best ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com