Adjustable and controllable three-dimensional thermal invisibility cloak based on multiple annular graphene layers

A multi-layer graphene, layer graphene technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as inability to open, thermal stealth function does not have tunability, etc., to save energy, improve computer performance, application Potential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

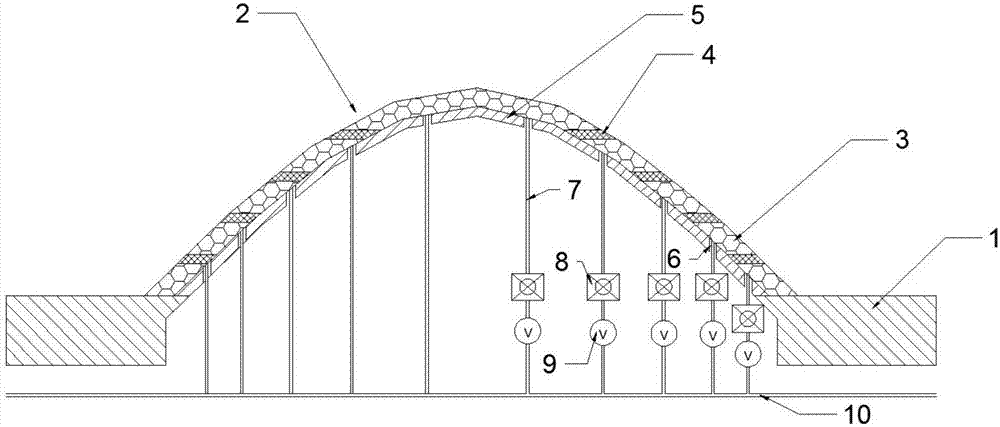

[0028] First, an internal support shell 5 is formed on the substrate 1 by a material growth process, as shown in Figure 2(a);

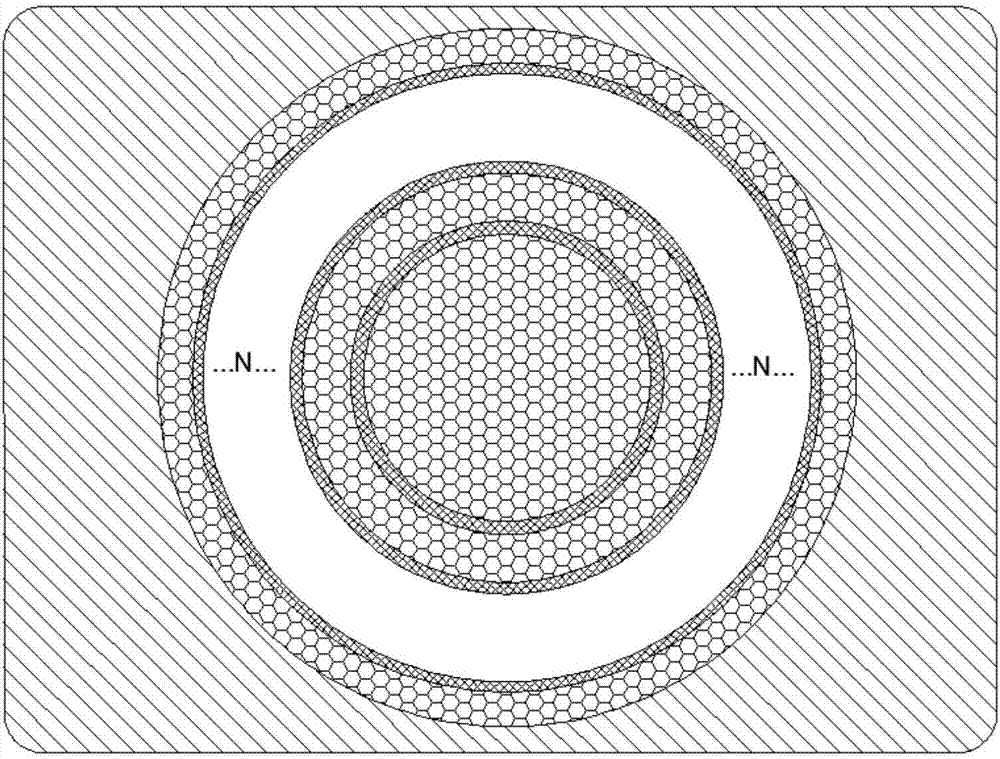

[0029] Then, through the material growth process and the mask process, the designed graphene ring layers are stacked layer by layer on the outer surface of the substrate 1 and the inner support shell 5 from bottom to top to realize the N-layer graphene surface ring layer structure 2, such as Shown in accompanying drawing 2 (b). Among them, the design of the graphene surface ring layer and the internal support shell can use algorithms such as finite time domain difference method and finite element method.

[0030] Corresponding to each graphene ring layer, the inner supporting shell is drilled with small holes 6 . A wire 7 is installed in the small hole, one end of the wire is connected to the graphene ring layer, and the other end passes through the control unit 8 and the ground wire 10 of the energy supply unit 9. By manipulating the control unit 8,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com