Making method for instant dried flavored prawn

A production method and shrimp technology are applied in the directions of food ingredients as taste improvers, food science, food ingredients as odor improvers, etc., which can solve the problems of hard texture, unsanitary and low quality of products, and achieve soft, fresh, tender and preserved texture. Elastic, scented effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

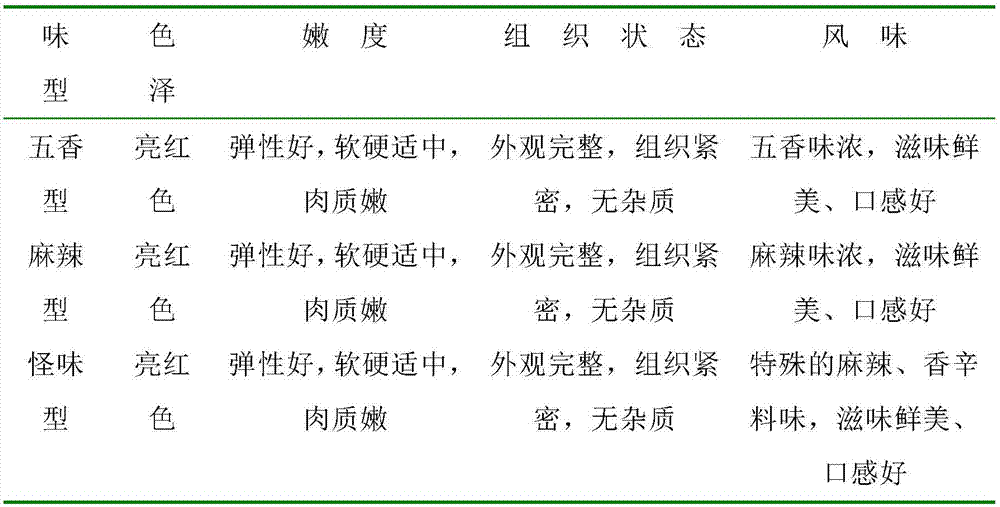

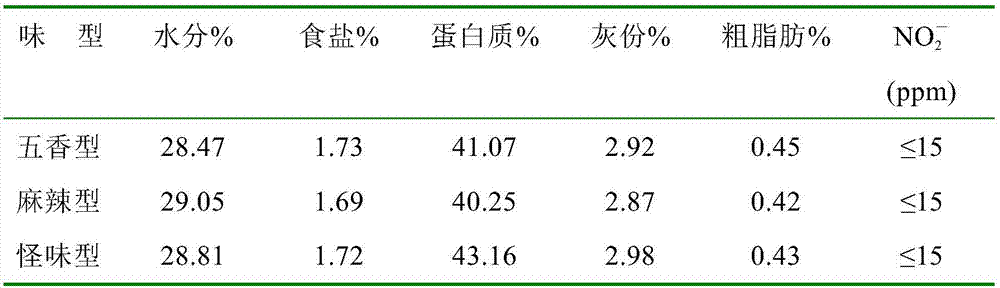

Embodiment 1

[0028] A preparation method (five-spice type) of flavor instant dried prawns, specifically comprising the following steps:

[0029] 1) Select fresh and live Penaeus vannamei shrimp with complete shrimp body, no corruption, and the same size, rinse with running water, remove the head and shell, remove the intestinal glands, and rinse the shrimp yellow with clean water;

[0030] 2) Add seasonings (2.0 parts of salt, 1.2 parts of monosodium glutamate, 2.5 parts of white sugar, 1 part of 55-degree Beijing Red Star Erguotou, 0.4 parts of five-spice powder, 2 parts of ginger, and 0.2 parts of pepper powder) in proportion and process in step 2) Shrimp, stir evenly, and marinate in a refrigerator at 4°C for 24 hours;

[0031] 3) Cook the prawns marinated in step 2) in a jacketed pot at 80°C for 12 minutes;

[0032] 4) Arrange the prawns cooked in step 3) neatly on a drying sieve, and dry in a cold air dryer at 50°C for 4 hours;

[0033] 5) packing the dried prawns through step 4), a...

Embodiment 2

[0036] A preparation method (spicy type) of flavor instant dried prawns, specifically comprising the following steps:

[0037] 1) Select fresh and live Penaeus vannamei shrimp with complete shrimp body, no corruption, and the same size, rinse with running water, remove the head and shell, remove the intestinal glands, and rinse the shrimp yellow with clean water;

[0038] 2) Seasoning (1.5 parts of salt, 0.8 parts of monosodium glutamate, 1 part of white sugar, 1.5 parts of Shaoxing Guyue Longshan Huadiao wine, 0.1 parts of five-spice powder, 3 parts of ginger, 3 parts of chili powder, 0.4 parts of pepper powder, 0.1 part of laurel , 0.2 parts of cardamom, and 0.3 parts of grass fruit) were added in proportion to the shrimps processed in step 2), stirred evenly and mixed, and marinated in a refrigerator at 4°C for 24 hours;

[0039] 3) Cook the prawns marinated in step 2) in a jacketed pot at 80°C for 12 minutes;

[0040] 4) Arrange the dried prawns cooked in step 3) neatly o...

Embodiment 3

[0044] A preparation method (strange taste type) of flavor instant dried prawns, specifically comprising the following steps:

[0045] 1) Select fresh and live Penaeus vannamei shrimp with complete shrimp body, no corruption, and the same size, rinse with running water, remove the head and shell, remove the intestinal glands, and rinse the shrimp yellow with clean water;

[0046] 2) Seasoning (1.8 parts of salt, 1.2 parts of monosodium glutamate, 3 parts of soy sauce, 2 parts of white sugar, 1 part of Beijing Red Star Erguotou, 0.3 parts of five-spice powder, 2 parts of old ginger, 0.2 parts of pepper powder, 2 parts of chili powder, Chinese prickly ash 0.3 part powder, 0.2 part laurel, 0.5 part tangerine peel, 0.1 part kale, 0.2 part cardamom, and 0.3 part grass fruit) are added in proportion to the shrimps treated in step 2), stirred evenly, and marinated in a refrigerator at 4°C for 24 hours ;

[0047] 3) Cook the prawns marinated in step 2) in a jacketed pot at 80°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com