Titanium oxide photocatalyst loaded with iron compound

A photocatalyst, titanium oxide technology, applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, etc., can solve the problem of insufficient photocatalyst activity, etc. The effect of catalytic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

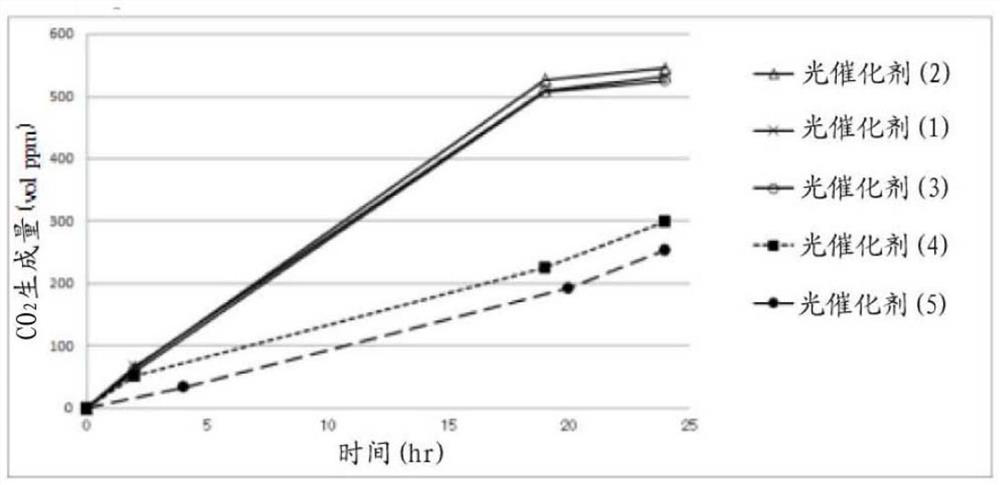

Embodiment 1

[0065] 10 g of titanium oxide (a mixture of rutile-type titanium oxide (20 wt %) and anatase-type titanium oxide (80 wt %), average particle size: 30 nm, specific surface area: 50 m 2 / g, trade name "AEROXIDE TiO 2 P25" (manufactured by Japan Aerosil Co., Ltd.) and 90 g of ion-exchanged water were stirred and mixed to obtain a suspension.

[0066] 0.15 g of iron (III) chloride aqueous solution (iron (III) chloride concentration: 38 weight %) was added to the obtained suspension, and it stirred at 25 degreeC for 30 minutes. Then, 2.3 g of methanol (corresponding to 23% by weight of titanium oxide) was added, and ultraviolet rays (UV) were irradiated for 6 hours using a 10W black light lamp (UV irradiation amount: 10 mW / cm) 2 ).

[0067]Then, the suspension was placed in a high-speed centrifugal precipitation machine (centrifugal force: 20,000 G, time: 10 to 20 minutes), and the powder was washed (washed with water until the conductivity of the supernatant was 200 μS / cm or les...

Embodiment 2

[0071] A photocatalyst (2) (iron content: 220 ppm, chlorine atom) was obtained in the same manner as in Example 1, except that the addition amount of the iron (III) chloride aqueous solution (38% by weight) was changed from 0.15 g to 0.075 g. Content: 600 ppm, iron element content / chlorine atom content: 0.37, average particle size: 30 nm).

Embodiment 3

[0073] A photocatalyst (3) (iron element content: 320 ppm, chlorine atom) was obtained in the same manner as in Example 1, except that the addition amount of the iron (III) chloride aqueous solution (38 wt %) was changed from 0.15 g to 0.3 g. Content: 760 ppm, iron element content / chlorine atom content: 0.42, average particle size: 30 nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com