Method for efficiently degrading polyvinyl alcohol material

A polyvinyl alcohol, high-efficiency technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of PVA degradation and low PVA concentration, so that it is not easy to secondary pollution, oxidant The effect of small amount and high efficiency degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

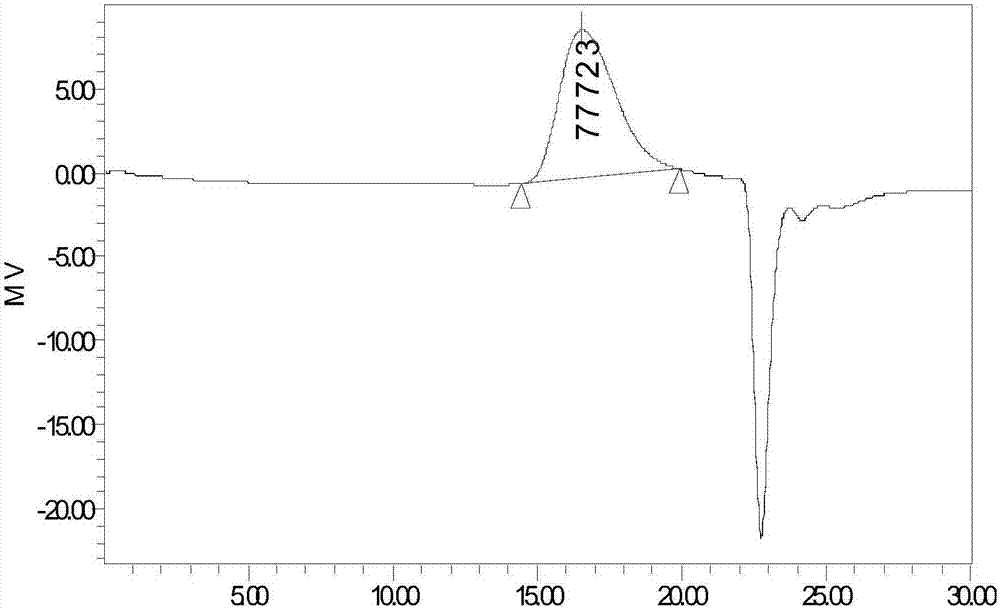

[0042] The step of carrying out degradation treatment by the present invention is as follows:

[0043] 1. Pretreatment of PVA material (1799 yarn): at room temperature, weigh 5g of PVA material, add deionized water, swell for 2 hours, then heat up to 60°C and keep stirring to dissolve. After the dissolution is complete, dissolve it with water The solution was adjusted to 100ml.

[0044] 2. Add 100ml of pretreated PVA solution into the reaction kettle, adjust the pH of the solution to 4 with hydrochloric acid, and slowly add 60ml of hydrogen peroxide with a mass concentration of 30% and a ferrous nitrate solution with a mass concentration of 30% while rotating and stirring. 40ml, the addition rate of hydrogen peroxide and ferrous nitrate solution is 15ml / h and 10ml / h respectively, the molar ratio of hydrogen peroxide and ferrous nitrate is 8.81:1, and it is oxidatively degraded at 60°C for 1 hour.

[0045]3. Add 20ml of sodium hydroxide solution with a mass concentration of 20...

Embodiment 2

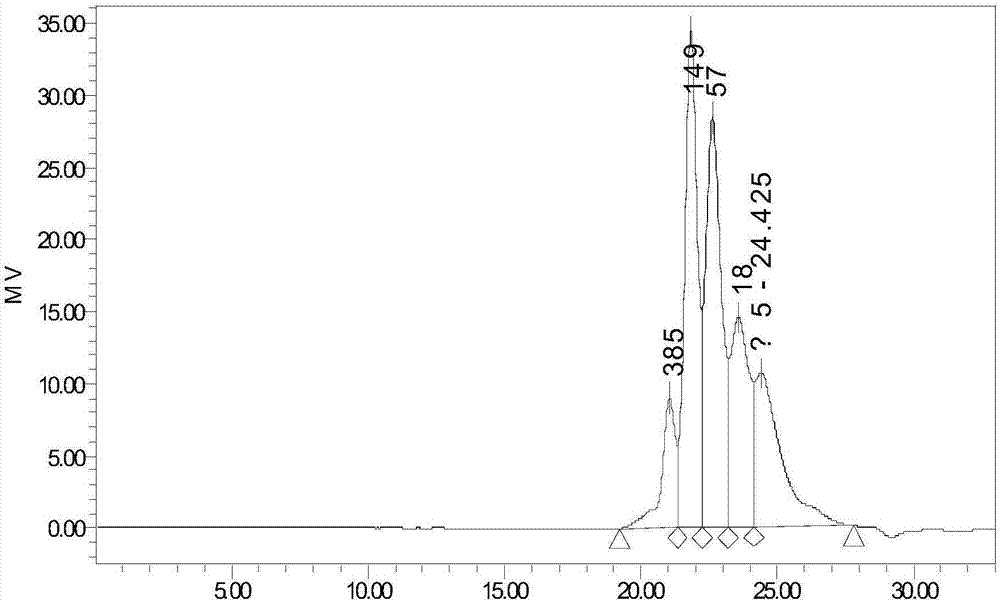

[0049] The step of carrying out degradation treatment by the present invention is as follows:

[0050] 1. Pretreatment of PVA material (1799 yarn): at room temperature, weigh 15g of PVA material, add deionized water, swell for 2 hours, then heat up to 90°C and stir to dissolve. After the dissolution is complete, dissolve the solution Dilute to 100ml.

[0051] 2. Add 100ml of pretreated PVA solution into the reaction kettle, adjust the pH of the solution to 3 with sulfuric acid, and slowly add 120ml of hydrogen peroxide with a mass concentration of 15% and ferrous chloride with a mass concentration of 25% while rotating and stirring. Solution 40ml, oxidant and catalyst adding rate are 30ml / h and 10ml / h respectively, the molar ratio of hydrogen peroxide and ferrous nitrate is 7.50:1, at 80 ℃, oxidative degradation is 2 hours.

[0052] 3. Add 30ml of sodium hydroxide solution with a mass concentration of 20% to the solution after oxidative degradation, and adjust the pH of the s...

Embodiment 3

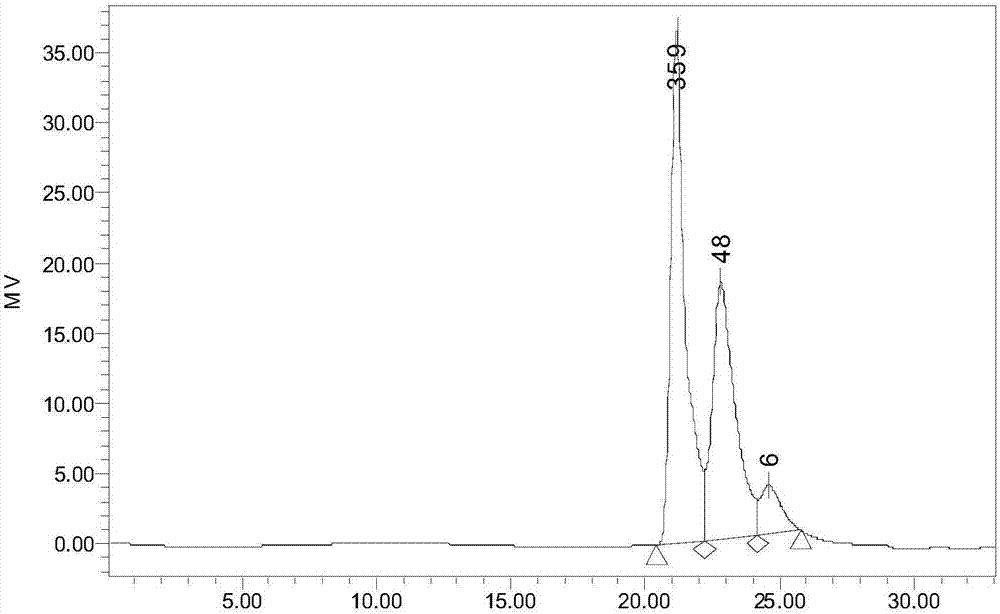

[0055] The step of carrying out degradation treatment by the present invention is as follows:

[0056] 1. Pretreatment of PVA material (1799 yarn): at room temperature, weigh 8g of PVA material, add deionized water, swell for 2 hours, then heat up to 80°C and stir to dissolve. After the dissolution is complete, dissolve the solution Dilute to 100ml.

[0057] 2. Add 100ml of the pretreated PVA solution into the reaction kettle, adjust the pH of the solution to 5 with nitric acid, and slowly add 60ml of hydrogen peroxide with a mass fraction of 30% and a ferrous bromide solution with a mass fraction of 15% while rotating and stirring. 80ml, the addition rate of oxidizing agent and catalyst is 20ml / h and 10ml / h respectively, the molar ratio of hydrogen peroxide and ferrous nitrate is 10:1, at 50 ℃, oxidative degradation is 1 hour.

[0058] 3. Add 20ml of sodium hydroxide solution with a mass concentration of 20% to the solution after oxidative degradation, and adjust the pH of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com