Preparation method of high-light-transmittance photovoltaic coated glass

A technology of coated glass and high light transmittance, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of uneven film thickness, unsuitable for industrialized large-area coating, and difficult to control the pulling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

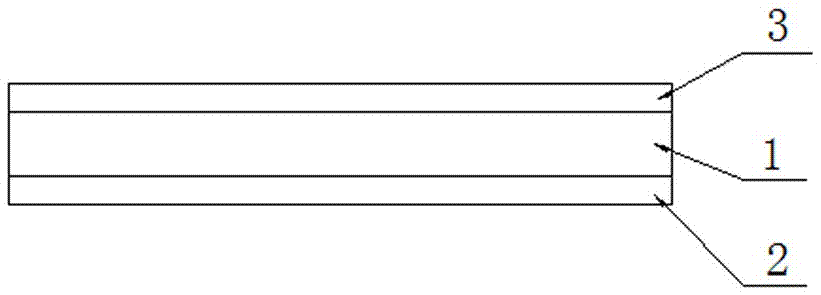

[0029] Embodiment 1: as attached figure 1 As shown, a photovoltaic coated glass with high light transmittance is provided with an anti-reflection layer 3 on the smooth surface of the glass 1, and an anti-reflection layer 2 is provided on the embossed surface of the glass 1. The anti-reflection layers are all low refraction rate porous silica coating with a thickness of 120 nm.

Embodiment 2

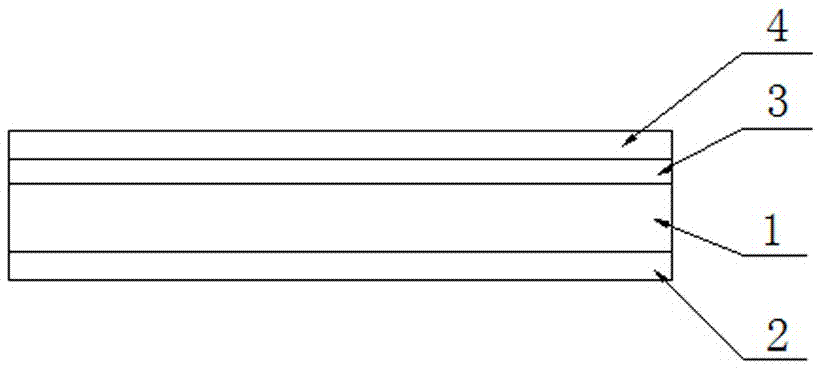

[0030] Embodiment 2: as attached figure 2 As shown, another high-transmittance photovoltaic coated glass is provided with two layers of anti-reflection layers on the smooth surface of glass 1, and one layer of anti-reflection layer 2 is arranged on the embossed surface of glass 1, and its thickness is 110nm. The first anti-reflection layer arranged on the smooth surface is a high-refractive index coating 3 with a thickness of 50nm, and the high-refractive index coating is composed of zirconia and silicon oxide; the second anti-reflection layer arranged on the smooth surface It is a low-refractive-index porous silicon oxide coating 4 provided on the high-refractive-index coating 3, and its thickness is 130 nm.

Embodiment 3

[0031] Embodiment 3: The third kind of high light transmittance photovoltaic coated glass is provided with a layer of anti-reflection layer on the smooth surface of the glass, and a layer of anti-reflection layer is provided on the embossed surface of the glass, and the anti-reflection layers are all low refraction rate porous silica coating with a thickness of 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com