An edge-emitting semiconductor laser device and its manufacturing method

A technology of laser device and manufacturing method, applied in semiconductor lasers, laser parts, lasers, etc., can solve the problem of high laser manufacturing cost, and achieve the effects of reducing cavity surface loss, reducing manufacturing cost, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

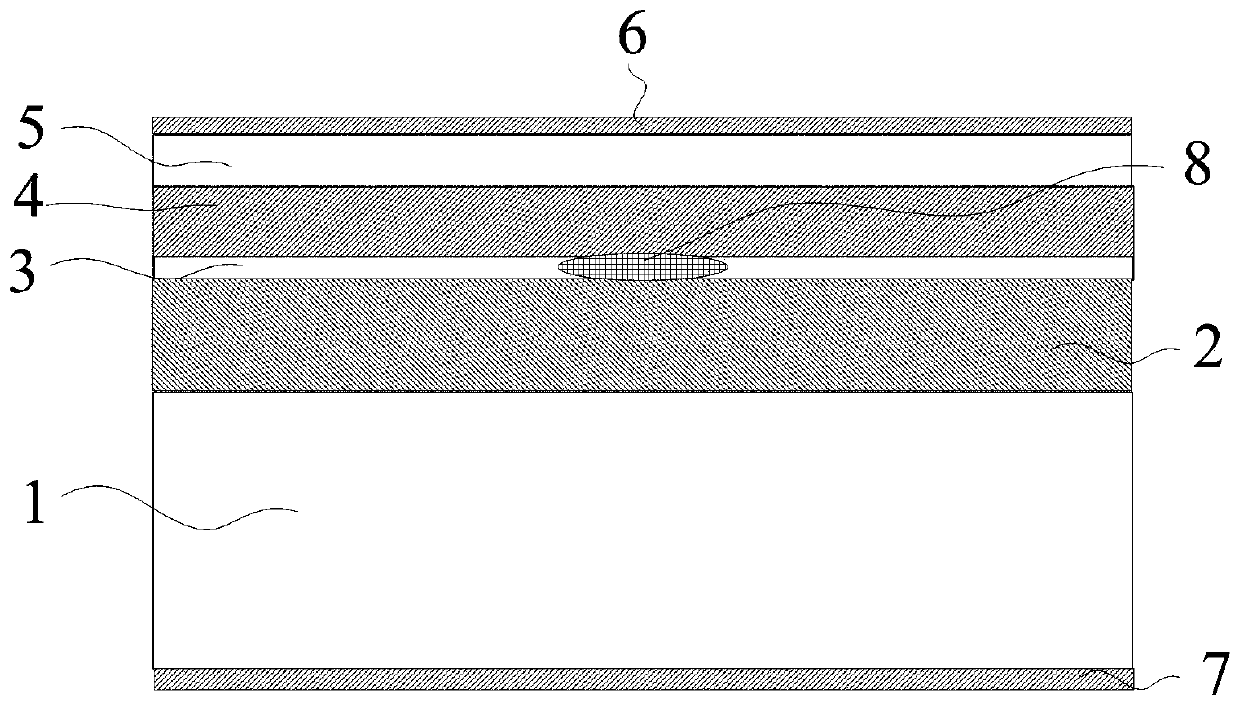

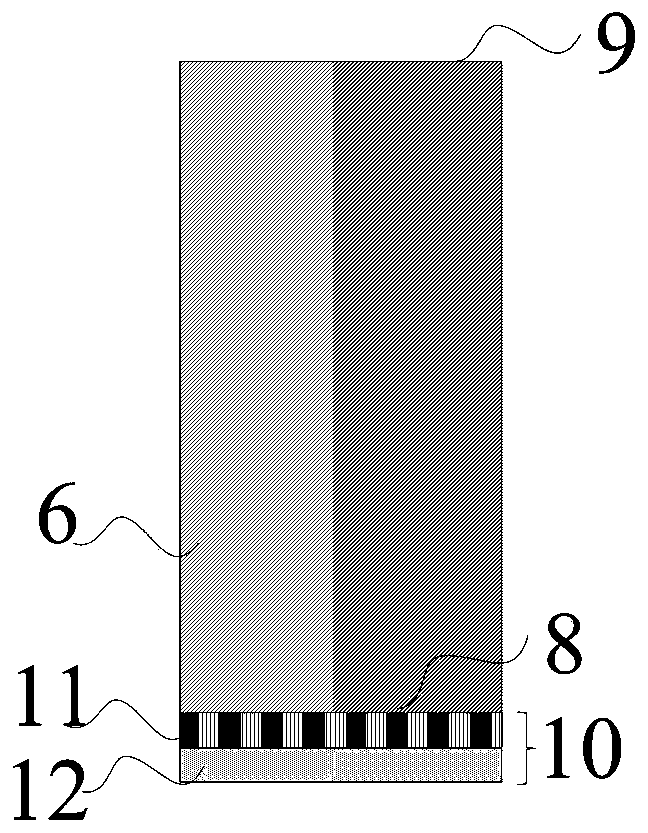

[0041] Such as figure 1 and figure 2 Shown, a kind of edge emission semiconductor laser device, it comprises substrate (1), the semiconductor epitaxial layer that is deposited on the substrate and is located at the reflective end face (8) and the exit end face (9) of semiconductor epitaxial layer surface, this semiconductor The epitaxial layer includes a first conductive coating layer (2), a light-emitting layer (3) and a second conductive coating layer (4) from bottom to top, and a second electrode (6) is arranged at one end of the second conductive coating layer (4). ), the bottom of the substrate (1) or one end of the first conductive cladding layer (2) is provided with a first electrode (7), and the reflective end surface (8) is provided with a periodic dielectric composite layer (10). Such as figure 2 As shown, the periodic dielectric composite layer (10) is composed of two parts: a three-dimensional periodically arranged dielectric layer (11) and a low refractive ind...

Embodiment 2

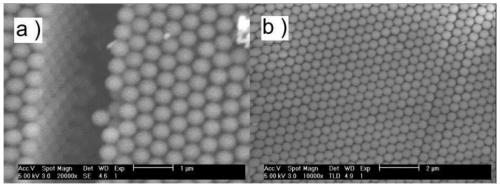

[0051] The basic structure adopted in the second embodiment is the same as that of the first embodiment, except that the shape of the three-dimensional periodically arranged dielectric layer (11) is complementary to that of the first embodiment. The key to realizing Example 2 is to fill or synthesize a certain material in the gaps of the polystyrene pellets by means of physical infiltration or chemical synthesis, and burn out the polystyrene pellets by high-temperature annealing. A specific embodiment is: SnCl4.5H2O (1.4g, 4mmol) and ethanol (20mL, 0.2M) are fully mixed. Saturated NH4F solution (0.5 g, 5 mmol) was added to the mixture and sonicated for 1 hour until the mixture was colorless. The sample obtained in Example 1 was placed in the mixed solution, placed in a vacuum box for 30 minutes and taken out. The sample was placed in a blast drying oven, the temperature was raised to 450°C at a rate of 1°C / min, and kept for 2 hours. The above process makes the precursor solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com