Production method of dried blueberries

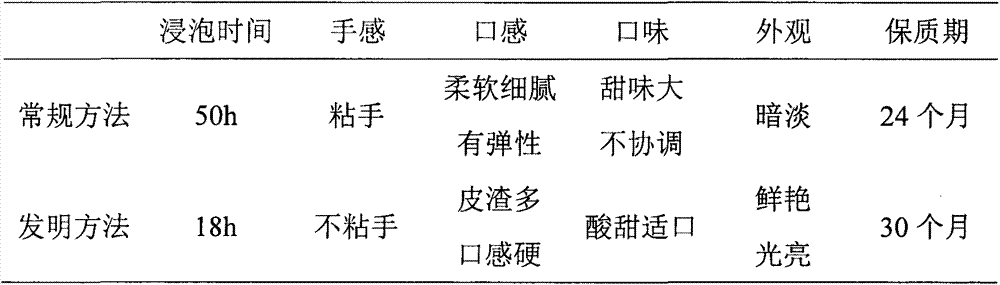

A production method and technology of blueberry fruit, which are applied in food ultrasonic treatment, confectionery, confectionary industry, etc., can solve the problems of single nutritional content, high surface viscosity, sour taste, etc., to increase nutritional content, brighten the surface, and improve taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Sorting, removing impurities, cleaning, and drying fresh blueberries of the rabbit-eye variety to obtain 10 kg of clean blueberries. Then quickly freeze in a -40°C refrigerator until the skin of the blueberry bursts. Prepare 15kg of soaking liquid, which contains 6kg of fructose syrup, 3kg of honey, 0.15kg of maltodextrin, 0.75kg of inulin, 0.6kg of seaweed polysaccharide, 0.6kg of arabinose, 0.015kg of tea polyphenol, and the rest is pure water. Then adjust the pH of the soaking solution to 4.5 with citric acid. Immerse 10kg of blueberries in the soaking solution, and carry out microwave treatment (400w), until the soaking solution boils, and keep boiling for 1min, and then soak at 20°C. Ultrasonic treatment (power 400w) was performed once for 15 minutes after soaking for 5h, 10h and 15h respectively. After 15 hours, drain the soaked blueberries, first dry them with hot air at 40°C for 8 hours, then dry them with hot air at 60°C for 15 hours, and finally dry them wit...

Embodiment 2

[0050]Fresh blueberries of the Blue Rain variety were sorted, removed, washed, and dried to obtain 5kg of clean blueberries. Then quickly freeze in a -80°C refrigerator until the skin of the blueberry bursts. Prepare 10kg of soaking liquid, which contains 5kg of fructose syrup, 1.5kg of honey, 0.3kg of maltodextrin, 0.8kg of inulin, 0.2kg of seaweed polysaccharide, 0.8kg of arabinose, 0.015kg of tea polyphenol, and the rest is pure water , and then adjust the pH of the soaking solution to 6.0 with citric acid. Immerse 5kg of blueberries in the soaking solution, and perform microwave treatment (600w) until the soaking solution boils, and keep boiling for 2 minutes, and then soak at 30°C. After soaking for 10h and 20h, respectively, perform a 20min ultrasonic treatment (power 300w). After 20 hours, drain the soaked blueberries, first dry them with hot air at 50°C for 5 hours, then dry them with hot air at 70°C for 10 hours, and finally dry them with hot air at 50°C until the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com