Chewing salt threshold tablets and preparation method thereof

A technology of threshold value and table salt, which is applied in food ingredients as taste improvers, food shaping, food science, etc. It can solve the problems of not being able to store for a long time, not being easy to preserve, and being easy to be polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] Specific embodiments: a chewable salt threshold tablet and its manufacturing method Specific embodiments:

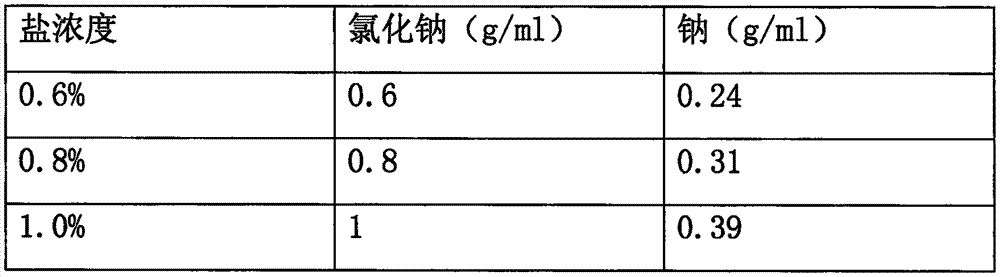

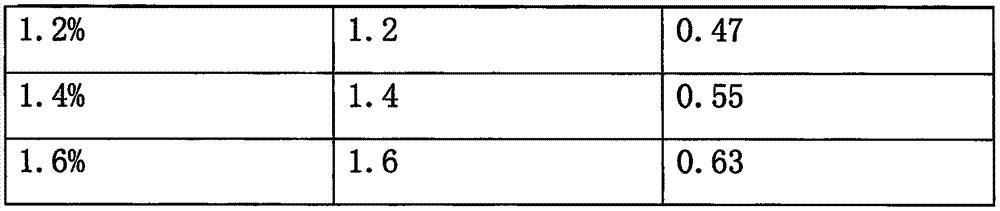

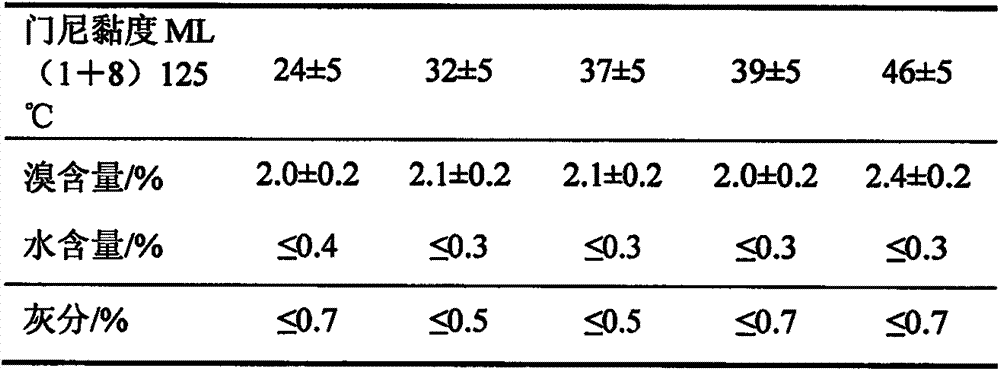

[0037] The present invention can use the following medical grade brominated butyl rubber with different Mooney viscosity ML(1+8) 125°C, bromine content / %, water content / %, ash content / % rubber

[0038]

[0039] Plasticize medical grade bromobutyl rubber in an open mill or internal mixer, and add food grade talcum powder, food grade calcium carbonate, food grade di Silicon oxide, plasticizer food oil, table salt. After mixing evenly in the open mill or internal mixer, use the unloading machine to make a mixed film, and then use the two-roller to make a film, and then apply food-grade polyethylene film on the mixing film. On the film, cut the output film to the specified size with a thermal cutting machine, and pack it to manufacture the export chewing salt threshold film.

[0040] A chewing salt threshold tablet of the present invention is composed in parts by...

Embodiment 1

[0044] In parts by weight, Mooney viscosity ML (1+8) 125 ° C 37 ± 5 medical grade bromobutyl rubber 10 kg, the medical grade brominated butyl rubber is masticated in an open mill, the roller distance is 0.2mm, The temperature of the front roller is 30-40°C, the temperature of the rear roller is 40-50°C, and the mastication time is 10-12 minutes. Then, the masticated medical grade bromobutyl rubber is mixed with an open mill, and the roller distance is 2mm. When the temperature of the front roller is 30-40°C and the temperature of the rear roller is 40-50°C, after kneading in the open mill for 2 minutes, adjust and add food-grade talcum powder in turn with a purity of more than 99% and a fineness of more than 325 mesh, parts by weight 3.5 kg; food-grade calcium carbonate has a purity of more than 99%, a fineness of more than 325 mesh, and a weight of 1.4 kg; a food-grade silica with a purity of more than 99%, a fineness of more than 1250 mesh, and a weight of 0.6 kg; Plasticize...

Embodiment 2

[0046]In parts by weight, Mooney viscosity ML(1+8) 125°C 37±5 medical grade bromobutyl rubber 20 kg, masticating medical grade bromobutyl rubber in an internal mixer at a temperature of 80-90°C , the mastication time is 1-2 minutes, and then the masticated medical grade bromobutyl rubber is mixed with an internal mixer. The purity of food-grade calcium carbonate is above 325 mesh, and the weight part is 7 kg; the purity of food-grade calcium carbonate is above 99%, the fineness is above 325 mesh, and the weight part is 2.8 kg; the purity of food-grade silica is above 99%, and the fineness is 1250 mesh Above, 1.2 kg by weight; 4.4 kg of plasticizer food camellia oil; open the cooling water to keep the front roller temperature 80-95 ℃, mix in the internal mixer for 6-7 minutes, add salt and sodium chloride, the purity is 99 % or more, the fineness is more than 325 mesh, and the weight part is 0.9 kg; after refining for 2-3 minutes, the material is discharged from the internal mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com