Device and method for cutting carbon fiber composite material under induction of optical fiber pulse laser

A pulsed laser and composite material technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problem of low oxidation initiation temperature, reduce the temperature range, suppress heat transfer, and suppress residual The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

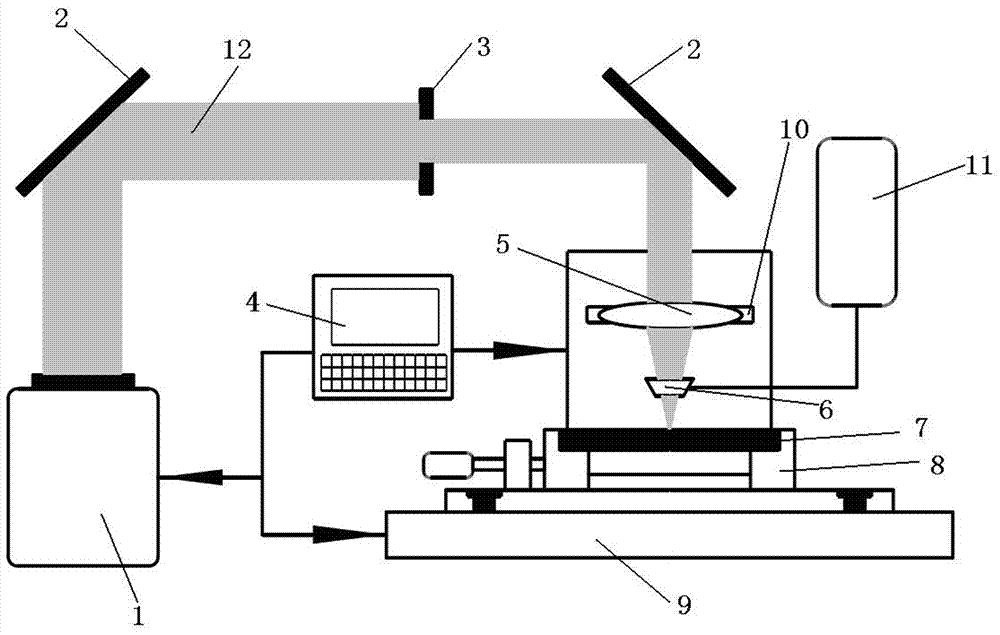

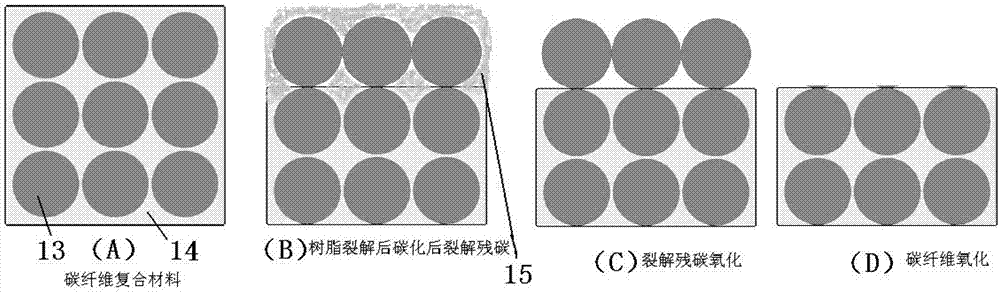

[0021] Such as Figure 1-2 As shown, the present invention is a device for fiber pulse laser induced cutting of carbon fiber composite materials, including a three-axis numerical control workbench controlled by a computer control system 4, and the three-axis numerical control workbench includes an X-Y platform 9 and a Z axis 10. The X-Y platform 9 is provided with a carbon fiber composite material laminated plate 7 clamped by a clamp 8, and a fiber pulse laser 1 is provided on one side of the three-axis numerical control workbench, and the laser beam 12 emitted by the fiber pulse laser 1 passes through the Several mirrors 2, filters 3 and lenses 5 are focused on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com