Modularized integration method for treating soy sauce brewing wastewater

A technology of brewing wastewater and integrated methods, which is applied in the direction of food industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., to achieve the effects of good impact load resistance, less land occupation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

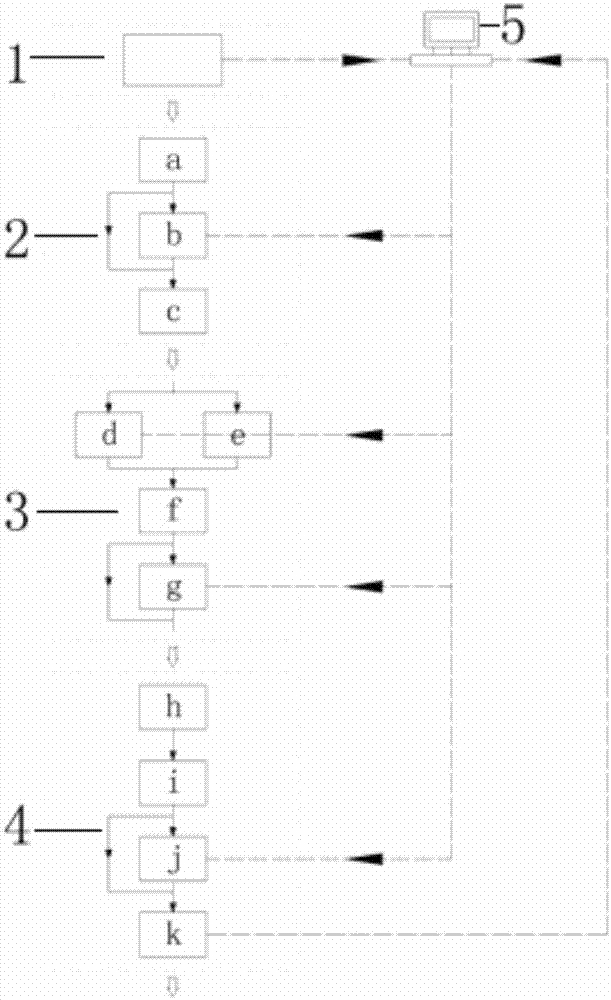

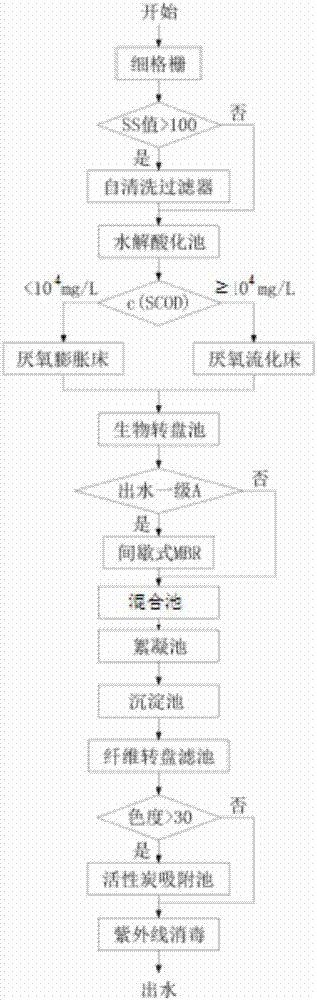

[0057] Such as Figure 1-Figure 2 As shown, in the specific implementation process, the process route of the modular integration method suitable for soy sauce brewing wastewater treatment of the present invention is water inlet → online water quality monitoring system 1 → first-level pretreatment module 2 → second-level biochemical module 3 → third-level Advanced treatment module 4 → water outlet, the specific process is as follows:

[0058] An online water quality monitoring system 1 is installed at the water inlet. Through the collection and analysis of the water quality information of incoming raw water, the results are output to the automatic control system 5, and the automatic control system 5 sends information to each module (first-level pretreatment module 2, second-level biochemical Module 3, three-level advanced processing module 4) or sub-module units send out signals to control the automatic operation of the overall process. The treated soy sauce brewing wastewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com