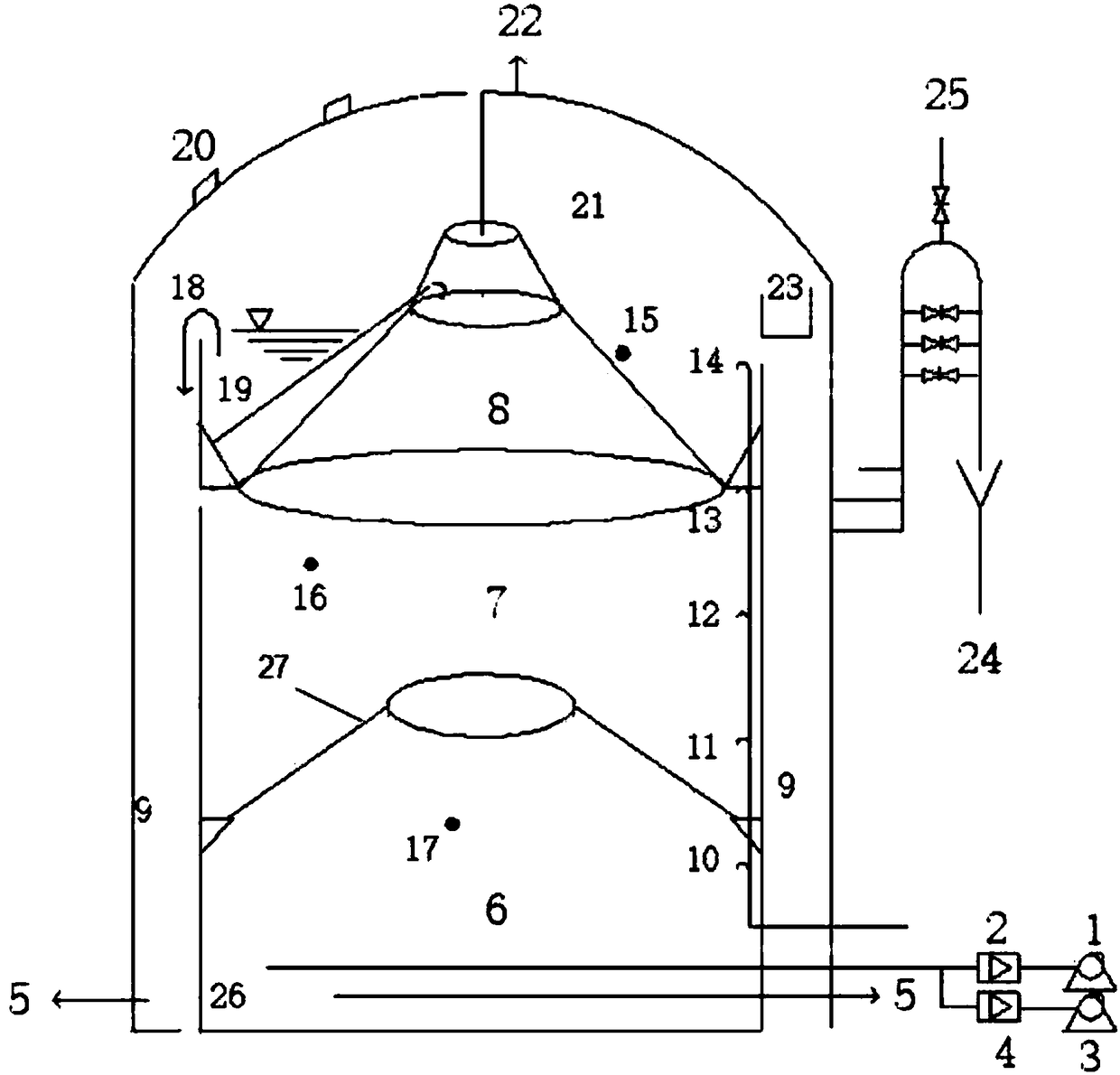

Novel UASB (Upflow Anaerobic Sludge Blanket) combined ABR (Anaerobic Baffled Reactor) granular sludge reactor and use method

A granular sludge and reactor technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problem of slow formation of granular sludge, consumption of manpower, material and financial resources, reaction It solves the problems of long startup time and other problems, so as to achieve the effect of small footprint and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

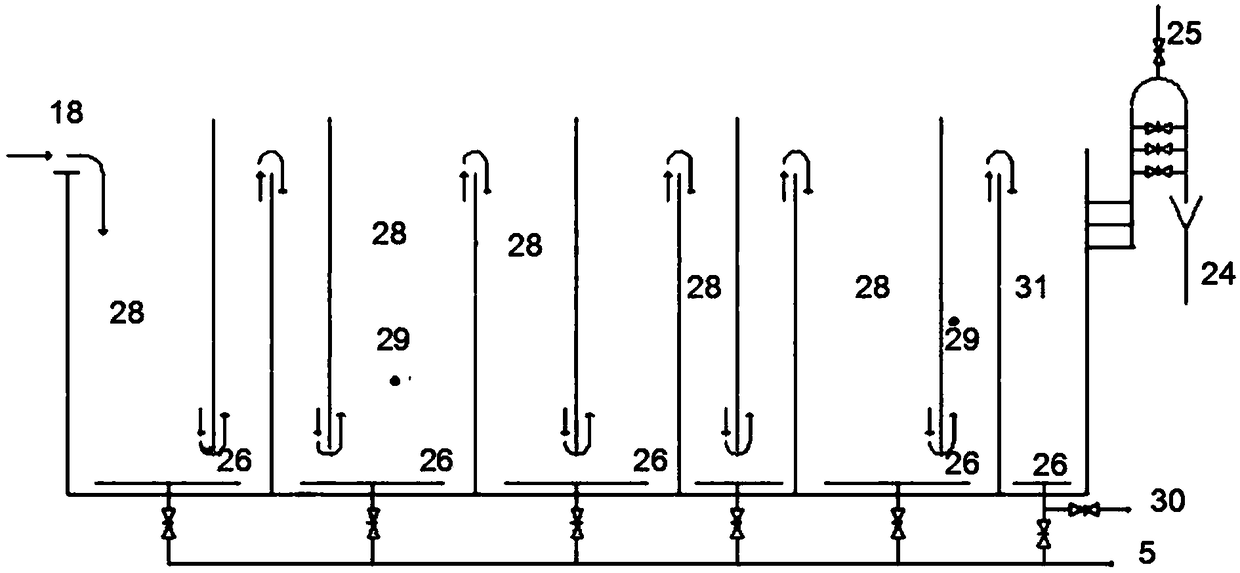

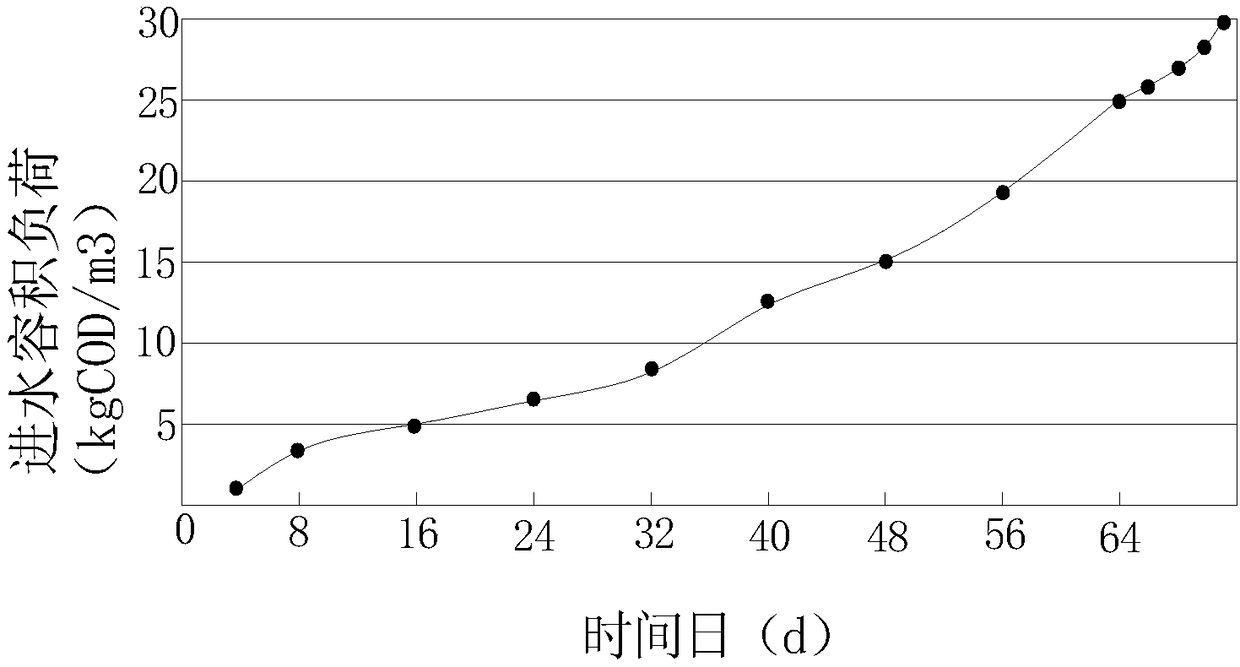

[0049] The start-up and commissioning device and process of the new UASB combined with ABR granular sludge reactor:

[0050] A new type of UASB combined with ABR granular sludge reactor is used to treat brewing wastewater produced from sorghum, wheat, rice, corn, dried melon, and cassava. The effective volume of the reactor for startup and commissioning is 1000m 3 , made of cylindrical carbon steel body, with an effective height of 14.8 meters. The reactor is digested and fermented at a medium temperature (34-36°C) and the insulation layer is used outside the cylinder for insulation, so as to facilitate the temperature control of digestion and fermentation in the carbon steel cylinder, and the waste water is controlled by speed regulation The constant flow pump is injected through the distributor at the bottom of the reactor, and the water from the overflow weir at the upper part of the three-phase separator enters the ABR plug-flow reaction chamber. Then it flows into a settl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com