A kind of primary amide quaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier and preparation method thereof

A technology of sodium hydroxypropyl sulfonate and asphalt emulsifier, which is applied in the direction of sulfonate preparation, cyanide reaction preparation, chemical instruments and methods, etc. It can solve the problems of high temperature reaction, need for high temperature reaction, high cost, etc., and achieve improved emulsification Performance, increasing hydrophilicity, enhancing the effect of charge strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

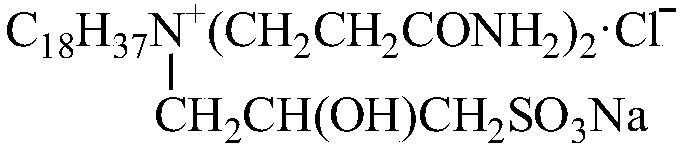

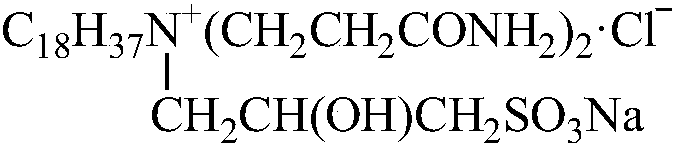

[0051] In one embodiment of the present invention, the preparation method of above-mentioned primary amide quaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier is provided, comprising the steps:

[0052] (1) Add octadecylamine into the reaction vessel, add alcohol solvent, heat and stir to dissolve, then add acrylamide in batches, after the addition, stir and react at 60-80°C for 2-4h to obtain reaction intermediate I;

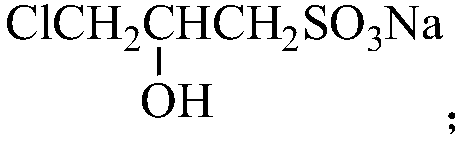

[0053] (2) Add sodium bisulfite to another reaction vessel, add water, heat and stir to dissolve, then add epichlorohydrin in batches, after the addition, stir and react at 40-85°C for 3-6h to obtain a reaction intermediate II (sodium 3-chloro-2-hydroxypropyl sulfonate);

[0054] (3) Add the reaction intermediate II to the reaction intermediate I in batches, and react at 60-80° C. for 3-6 hours to obtain the primary amide quaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier.

[0055] The applicant found un...

Embodiment 1

[0063] (1) Preparation of primary amide quaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier:

[0064] 1) Add 269.5g octadecylamine, 260g isopropanol in the reactor, heat and stir to dissolve. Then 145.7g of acrylamide was gradually added, and the reaction was stirred at 70°C for 3h.

[0065] The above synthetic product was separated and purified by recrystallization and then detected by FTIR. The results are as follows: 3371cm -1 and 3205cm -1 The N-H stretching vibration absorption peak at 2916cm -1 and 2850cm -1 The asymmetric and symmetric stretching vibration absorption peaks of methylene respectively, 1666cm -1 It is the amide group C=O stretching vibration absorption peak, 1471cm -1 is the asymmetric bending vibration of methylene, 1417cm -1 is the asymmetric bending vibration of the methyl group, 1263cm -1 and 1128cm -1 C-N stretching vibration absorption peak, 717cm -1 It is the in-plane rocking vibration of methylene, 669cm -1 is ...

Embodiment 2

[0079] (1) Preparation of primary amide quaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier:

[0080] 1) Add 269.5g octadecylamine and 260g absolute ethanol in the reactor, heat and stir to dissolve. Then 145.7g of acrylamide was gradually added, and the reaction was stirred at 70°C for 3h.

[0081] 2) Add 122.6g of sodium bisulfite and 392.7g of water into another reactor, stir to dissolve, and heat to 75°C. Then 98.9g of epichlorohydrin was added dropwise, and stirred at 75°C for 3.5h to obtain 3-chloro-2-hydroxypropyl sodium sulfonate aqueous solution.

[0082] 3) The aqueous solution of sodium 3-chloro-2-hydroxypropyl sulfonate prepared in step 2) was added dropwise to the synthesis product in the above step 1), and stirred at 75° C. for 3 h. The primary amide quaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier was obtained, which was reserved for the emulsified asphalt test.

[0083] (2) Preparation of emulsified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com