Porous needle, medicine-dispensing device and medicine-dispensing method

A dispensing device and technology of hole needles, which are applied in the field of medical equipment, can solve problems such as the inability to suck out the liquid medicine, affect the dispensing dose, pollute the environment, etc., and achieve the effects of safe and reliable dispensing efficiency, high dispensing efficiency, and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

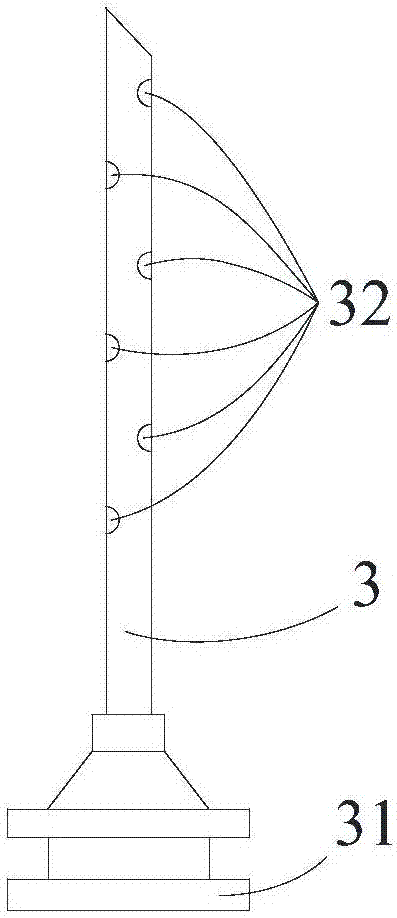

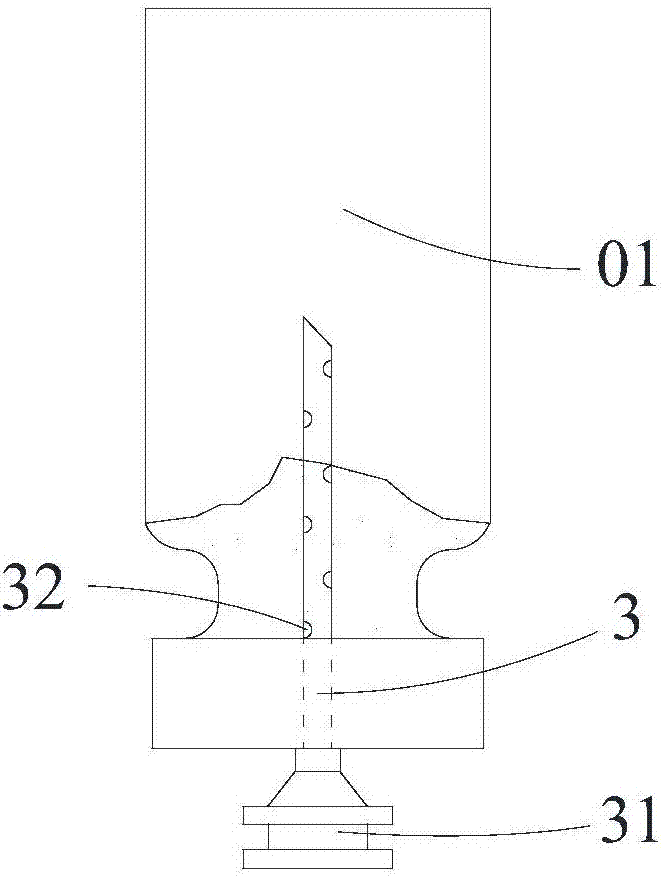

[0062] Such as Figure 1-2 As shown, a porous needle according to the present invention includes a needle tube 3 and a needle handle 31 connected thereto. The wall of the needle tube 3 is provided with at least one hole 32, and the hole 32 closest to the needle handle 31 is The distance to the needle handle 31 is equal to the thickness of the rubber stopper of the vial 01. When in use, the vial 01 is turned upside down, and the porous needle is inserted into the vial 01 from bottom to top.

[0063] As a preferred solution of this embodiment, the end of the needle tube 3 is conical. With this structure, the conical end is convenient for processing and inserting and closing the container cap.

[0064] Using the porous needle of the present invention, when dispensing medicine, the needle tube 3 is inserted into the rubber stopper of the vial 01 until the needle handle 31 touches the outer surface of the rubber stopper. At this time, the holes 32 on the needle tube 3 all enter the...

Embodiment 2

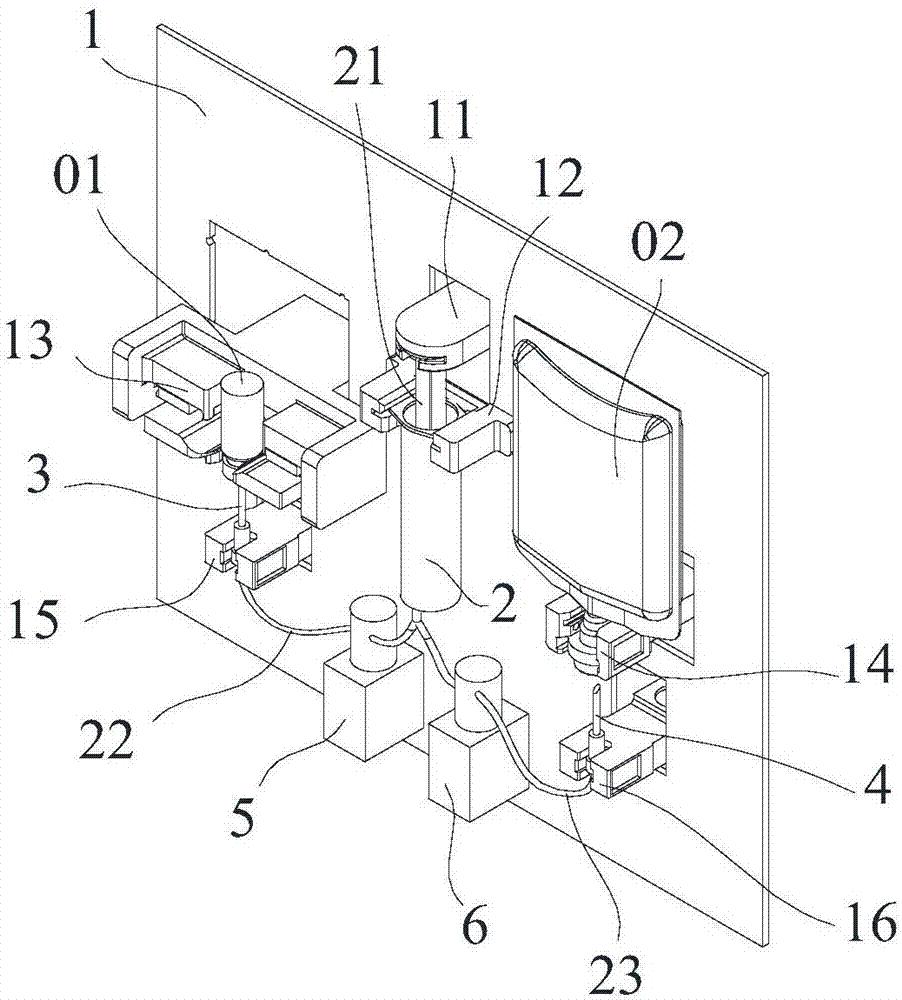

[0066] Such as Figure 1-6 As shown, a drug dispensing device according to the present invention includes a control system and a double-ended syringe 2 arranged on a base 1 .

[0067] The base 1 is provided with a linear reciprocating mechanism 11 that drives the piston rod 21 of the double-ended syringe 2 to move, and the two ends of the double-ended syringe 2 are connected to the first 22 and the second 23 respectively. The other end of conduit one 22 is connected to the porous needle as described in embodiment 1, and the porous needle is used to insert the vial 01, and the other end of conduit two 23 is connected to the needle 4 for inserting the infusion bag 02, and the vial 01 and the infusion bag 02 are set upside down on the base 1, the needle points of the porous needle and the needle 4 are set on the base 1 upward, and the vial 01 and the porous needle can face each other or opposite movement, the infusion bag 02 and the needle 4 can move toward or oppositely, the fi...

Embodiment 3

[0073] Such as Figure 1-7 As shown, a kind of dispensing method of the present invention uses the dispensing device as described in embodiment 2, and its dispensing method comprises the following steps:

[0074] a. Set the vial 01 and the infusion bag 02 upside down on the base 1;

[0075] b. The control system controls the first clamping part 5 and the second clamping part 6 to clamp the first conduit 22 and the second conduit 23 respectively;

[0076] c. The control system controls the vial 01 and the porous needle to move towards each other, the needle tube 3 of the porous needle is inserted into the vial 01, and the handle 31 of the porous needle contacts the rubber of the vial 01 plug, the control system controls the infusion bag 02 and the needle 4 to move toward each other, and the needle 4 is inserted into the infusion bag 02 and contacts the liquid medicine in the infusion bag 02;

[0077] d. The control system controls the clamping part 26 to loosen the conduit 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com