Self-propagating preparation method for Gd<2>Ti<2-x>Zr<x>O<7> pyrochlore

A self-propagating, pyrochlore technology, applied in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problems of unfavorable large-scale promotion of pyrochlore solidification process, long synthesis cycle, complex synthesis process, etc., to achieve guaranteed Stability and long-term safety, high product density and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] a Gd 2 Ti 2-x Zr x o 7 The self-propagating preparation method of pyrochlore comprises the following process steps:

[0050] (1) Using Ti as the reducing agent and CuO as the oxidizing agent, the ingredients are prepared according to the following reaction equation (I):

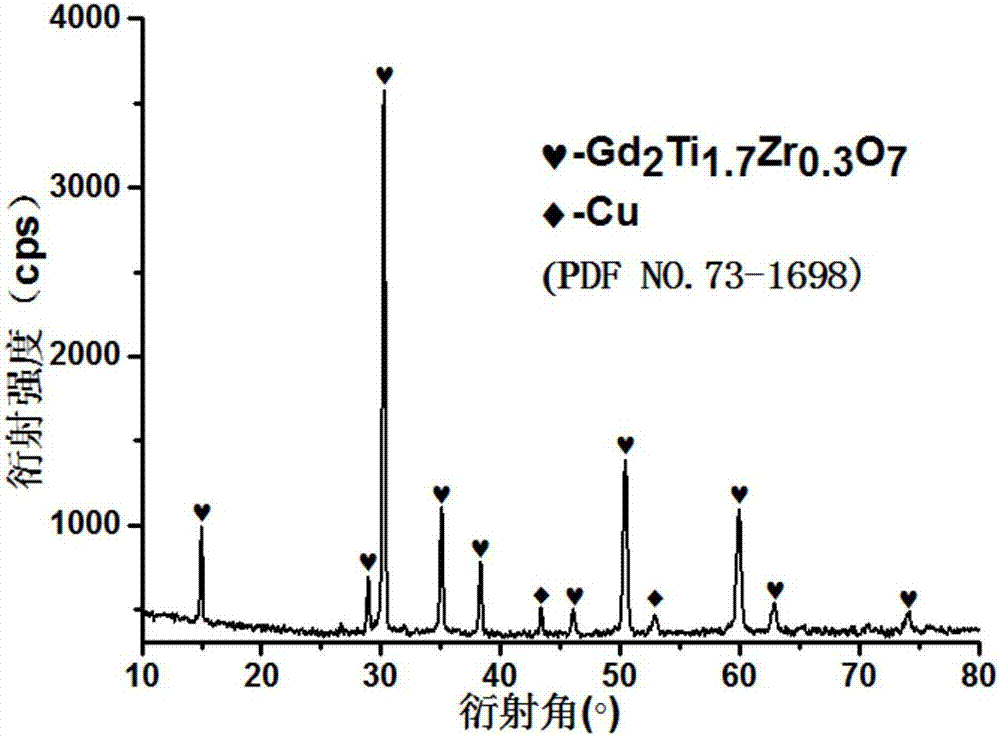

[0051] 3Ti+0.4TiO 2 +0.6ZrO 2 +2Gd 2 o 3 +6CuO=2Gd 2 Ti 1.7 Zr 0.3 o 7 +6Cu (I)

[0052] The molar ratio of each reactant raw material is Ti:TiO 2 : ZrO 2 :Gd 2 o 3 : CuO =15:2:3:10:30, according to their molecular weight and content, the corresponding mass percentage content is: Ti: 10.1%, TiO 2 : 2.25%, ZrO 2 : 5.2%, Gd 2 o 3 : 50.99%, CuO: 31.46%;

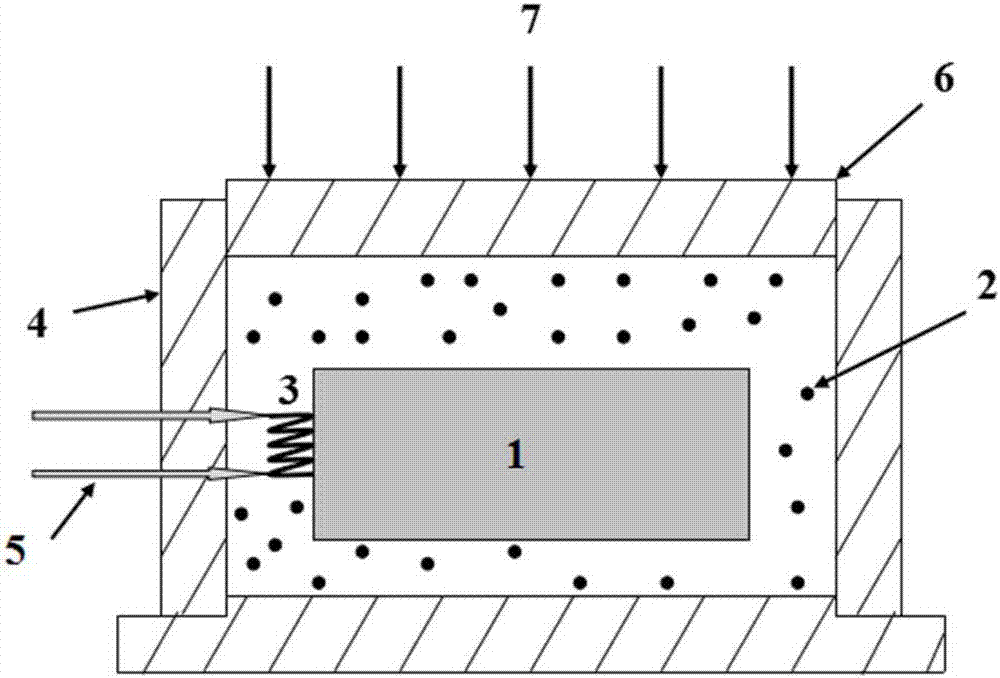

[0053] (2) Dry ball mill the above components for 30 minutes, mix them evenly, pass through a 100-mesh sieve to obtain a mixture, put it in an oven, and dry it at 80°C for 30 minutes. Take 20g of the mixture and put it into a Φ25mm stainless steel mold, press the mixture into a cylindrical blank 1 with a diameter of 25mm and a thickn...

Embodiment 2

[0057] a Gd 2 Ti 2-x Zr x o 7 The self-propagating preparation method of pyrochlore comprises the following process steps:

[0058] (1) Using Ti as the reducing agent and CuO as the oxidizing agent, the ingredients are prepared according to the following reaction equation (II):

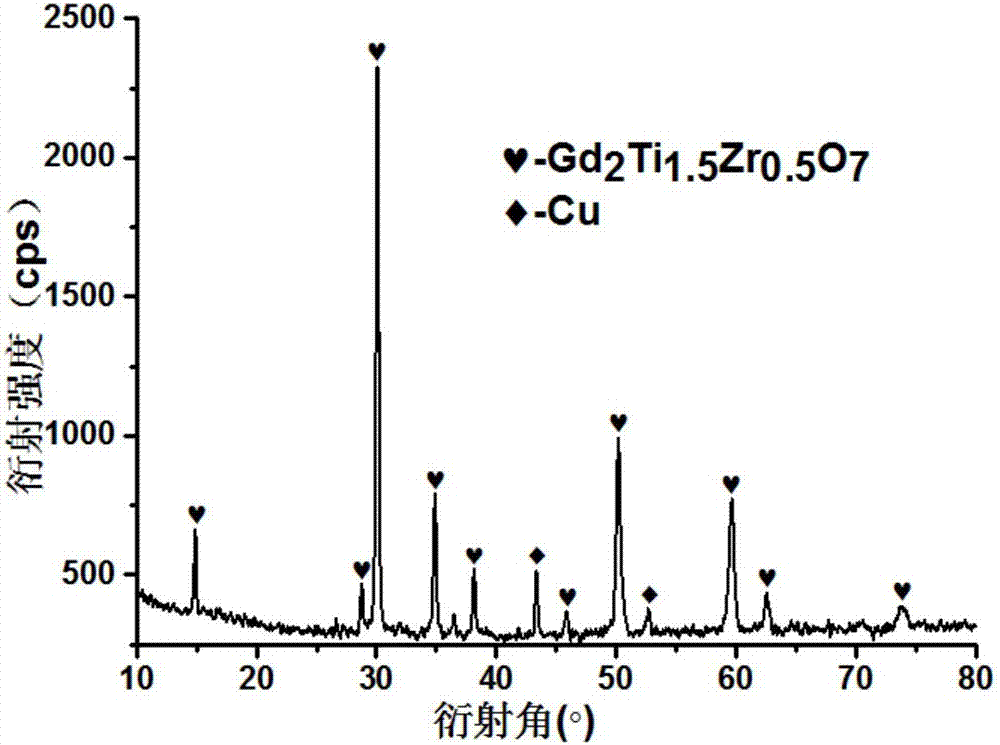

[0059] 3Ti+ZrO 2 +2Gd 2 o 3 +6CuO=2Gd 2 Ti 1.5 Zr 0.5 o 7 +6Cu (Ⅱ)

[0060] The molar ratio of each reactant raw material is Ti: ZrO 2 :Gd 2 o 3 : CuO=3:1:2:6, according to their molecular weight and content, the corresponding mass percentage content is: Ti: 9.77%, ZrO 2 : 8.39%, Gd 2 o 3 : 49.35%, CuO: 30.45%;

[0061] (2) Dry the raw materials of the above components for 30 minutes, mix them evenly, pass through a 100-mesh sieve to obtain the mixture, put it in an oven, and dry it at 80°C for 30 minutes. Take 20g of the mixture and put it into a Φ25mm stainless steel mold, press the mixture into a cylindrical blank 1 with a diameter of 25mm and a thickness of about 20mm by using a ...

Embodiment 3

[0065] a Gd 2 Ti 2-x Zr x o 7 The self-propagating preparation method of pyrochlore comprises the following process steps:

[0066] (1) Use Ti as the reducing agent and CuO as the oxidizing agent, and mix according to the reaction equation (II):

[0067] 13Ti+7ZrO 2 +10Gd 2 o 3 +26CuO=10Gd 2 Ti 1.3 Zr 0.7 o 7 +26Cu (Ⅱ)

[0068] The molar ratio of each reactant raw material is Ti: ZrO 2 :Gd 2 o 3 : CuO=13:7:10:26, according to their molecular weight and content, the corresponding mass percentage is: Ti: 8.67%, ZrO 2 : 12.02%, Gd 2 o 3 : 50.50%, CuO: 28.81%;

[0069] (2) Dry the raw materials of the above components for 30 minutes, mix them evenly, pass through a 100-mesh sieve to obtain the mixture, put it in an oven, and dry it at 80°C for 30 minutes. Take 20g of the mixture and put it into a Φ25mm stainless steel mold, press the mixture into a cylindrical blank 1 with a diameter of 25mm and a thickness of about 20mm by using a pressure of 20MPa;

[0070] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com