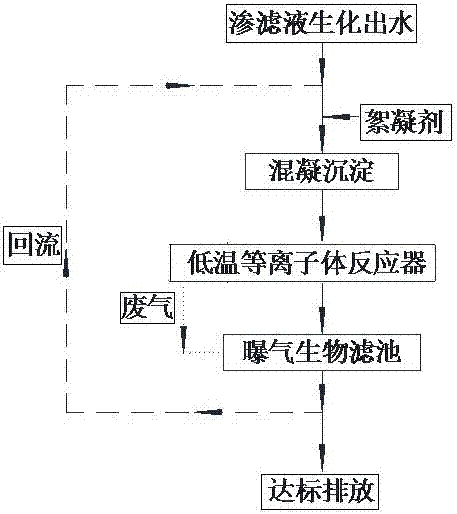

Deep treatment process of garbage percolate biochemical effluent

A technology of landfill leachate and biochemical effluent, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, multi-stage water/sewage treatment, etc., can solve problems such as difficult treatment, concentrated solution headaches, complex water quality, etc., to avoid pollution Environmental and treatment cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Add the flocculant polyaluminium chloride to the biochemical effluent of landfill leachate, the addition amount is 1g / L, then enter the coagulation sedimentation tank to mix well and let it settle.

[0021] (2) After precipitation, the landfill leachate enters the low-temperature plasma reactor, and passes through the strong oxidizing groups (H , O , OH , etc.) and strong oxidizing substances (H 2 o 2 , O 3 etc.), ultrasound, ultraviolet radiation, and high-energy electron bombardment, while contacting the ozone catalyst filled in the reactor, the organic matter is catalyzed and oxidized, and most of it is completely mineralized or decomposed into small molecules and easily biodegradable organic matter.

[0022] (3) The landfill leachate treated by the low-temperature plasma reactor enters the biological aerated filter, and the pollutants are biodegraded. In the biological aerated filter, the gas-water ratio is 4-7:1, and the landfill leachate is The residence tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com