Heat Treatment Method for Improving Strength-Plasticity Matching Properties of SLM Forming TC4

A heat treatment method and technology for matching performance, applied in the direction of energy efficiency improvement, process efficiency improvement, additive manufacturing, etc., can solve the problems of plasticity difference, small plasticity improvement, strength-plasticity matching performance difficult to meet the requirements of industrial engineering applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

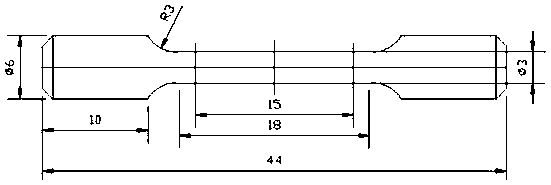

[0030] The Ti-6Al-4V powder particles with an average particle size of 45 μm and the composition shown in the parameter attached table 1 are used as the raw material for SLM forming. According to the process parameters shown in the parameter attached table 2, the forming size specification is 644mm, and the diameter of the working section is 3mm. Tensile specimen with a gauge length of 15mm, the specific size parameters are attached figure 2 .

[0031] Parameter Schedule 1

[0032]

[0033] Parameter Schedule 2

[0034]

[0035]

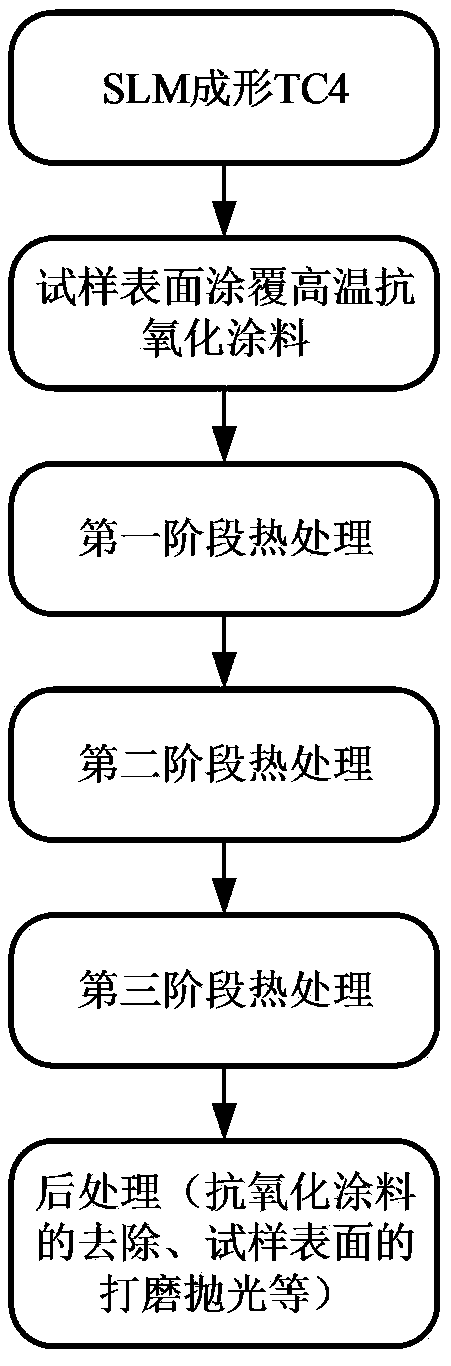

[0036] Use the wire cutting process to separate the tensile sample from the substrate, and then uniformly dip-coat a layer with a thickness of 0.2-0.3mm on the surface of the tensile sample, bonded by alumina, silicon oxide, boron carbide refractory and silicate High temperature anti-oxidation coating composed of additives.

[0037] Put the sample coated with high-temperature anti-oxidation coating into a vacuum atmosphere furnace, evacu...

Embodiment 2

[0044] The Ti-6Al-4V powder particles with an average particle size of 45 μm and the composition shown in the parameter attached table 1 are used as the raw material for SLM forming. According to the process parameters shown in the parameter attached table 2, the forming size specification is 644mm, and the diameter of the working section is 3mm. Tensile specimen with a gauge length of 15mm, the specific size parameters are attached figure 2 .

[0045] Parameter Schedule 1

[0046]

[0047] Parameter Schedule 2

[0048]

[0049]Use the wire cutting process to separate the tensile sample from the substrate, and then uniformly dip-coat a layer with a thickness of 0.2-0.3mm on the surface of the tensile sample, bonded by alumina, silicon oxide, boron carbide refractory and silicate High temperature anti-oxidation coating composed of additives.

[0050] Put the sample coated with high-temperature anti-oxidation coating into a vacuum atmosphere furnace, evacuate until the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com