Method for producing graphene by mechanically shearing and stripping

A mechanical shearing and graphene technology, applied in the research field of carbon nanomaterials, can solve the problems of high cost, difficult and high quality, environmental pollution, etc., and achieve the effect of low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

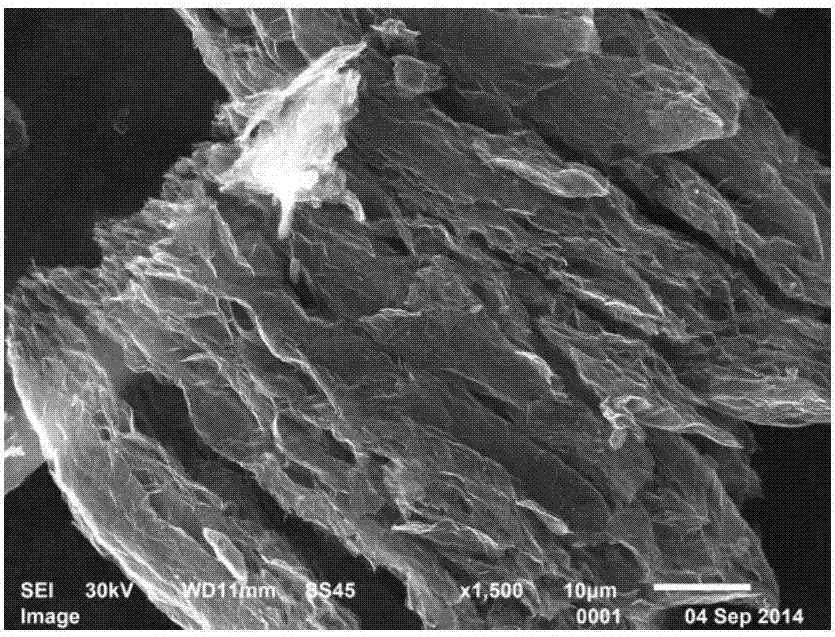

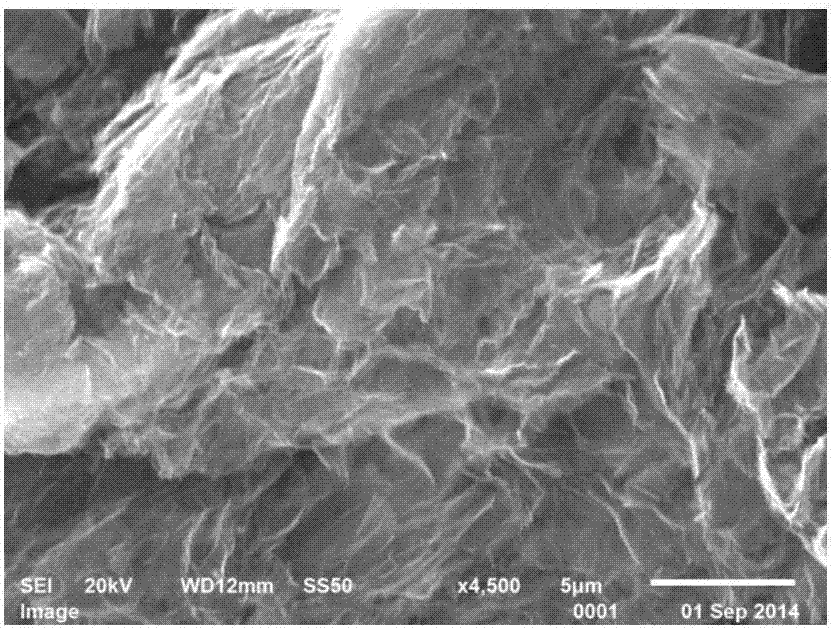

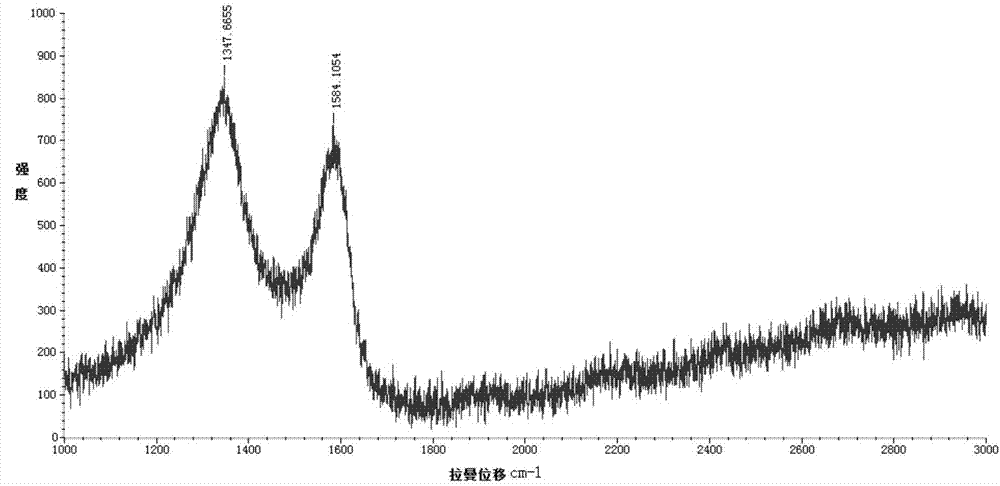

Image

Examples

Embodiment 1

[0023] A method for producing graphene by mechanical shear exfoliation, the method comprising the following steps: flake graphite and water are initially stirred and mixed to obtain a graphite mixed solution, the graphite mixed solution is subjected to high-shear exfoliation to obtain a graphene solution, and the graphene solution is centrifuged The graphene solution is obtained by processing, and the graphene solution is put into a vacuum drying oven to dry to obtain a graphene product.

[0024] Preliminary stirring and mixing steps: mix 10 g of flake graphite with 1000 g of pure water; stir with a stirrer at a stirring speed of 2000 r / min; the stirring time is 20 min, and the graphite mixed liquid is obtained after stirring.

[0025] High-shear stripping step: add 50.5g surfactant NMP (N-methylpyrrolidone) to the graphite mixed solution obtained by preliminary stirring and mixing, and the surfactant NMP and graphite mixed solution are mixed in a ratio of 5: 100 with a mass ra...

Embodiment 2

[0030] A method for producing graphene by mechanical shear exfoliation, the method comprises the following steps: the scaly graphite and water are initially stirred and mixed to obtain a graphite mixed solution, the graphite mixed solution is subjected to high-shear exfoliation to obtain a graphene solution, and the graphene solution is centrifuged The graphene solution is obtained by processing, and the graphene solution is put into a vacuum drying oven to dry to obtain a graphene product.

[0031] Preliminary stirring and mixing steps: mix 10 g of scaly graphite with 800 g of pure water; stir with a stirrer at a stirring speed of 1800 r / min; stir for 30 minutes, and obtain a graphite mixed liquid after stirring.

[0032] High-shear stripping step: add 56.7g surfactant NAC (N-acetylcysteine) to the graphite mixed solution obtained by preliminary stirring and mixing, and the ratio of surfactant NAC and graphite mixed solution is 7: 100 in mass ratio Mixing, using a high-speed ...

Embodiment 3

[0037] A method for producing graphene by mechanical shear exfoliation, the method comprising the steps of: mixing scaly and flake graphite with water to obtain a graphite mixed solution through preliminary stirring, and obtaining a graphene solution by high-shear exfoliating the graphite mixed solution, graphite The dilute solution is centrifuged to obtain a graphene solution, and the graphene solution is put into a vacuum drying oven to dry to obtain a graphene product.

[0038] Preliminary stirring and mixing steps: mix 10 g of scaly and flake graphite with 1200 g of pure water; stir with a stirrer at a stirring speed of 2200 r / min; stir for 30 min, and obtain a graphite mixed liquid after stirring.

[0039] High-shear stripping step: add 60g of surfactant NMP and NAC to the graphite mixture obtained by preliminary stirring and mixing, and mix the surfactant NMP, NAC and graphite mixture at a mass ratio of 5:100, and use a high-speed stripping machine Continuous shearing an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com