Fluidized biological rotary drum

A rotary drum and biological technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low biodegradation efficiency, low investment and operating costs, and low speed of biological turntables. Achieve the effect of improving energy saving effect, reducing driving difficulty and improving use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

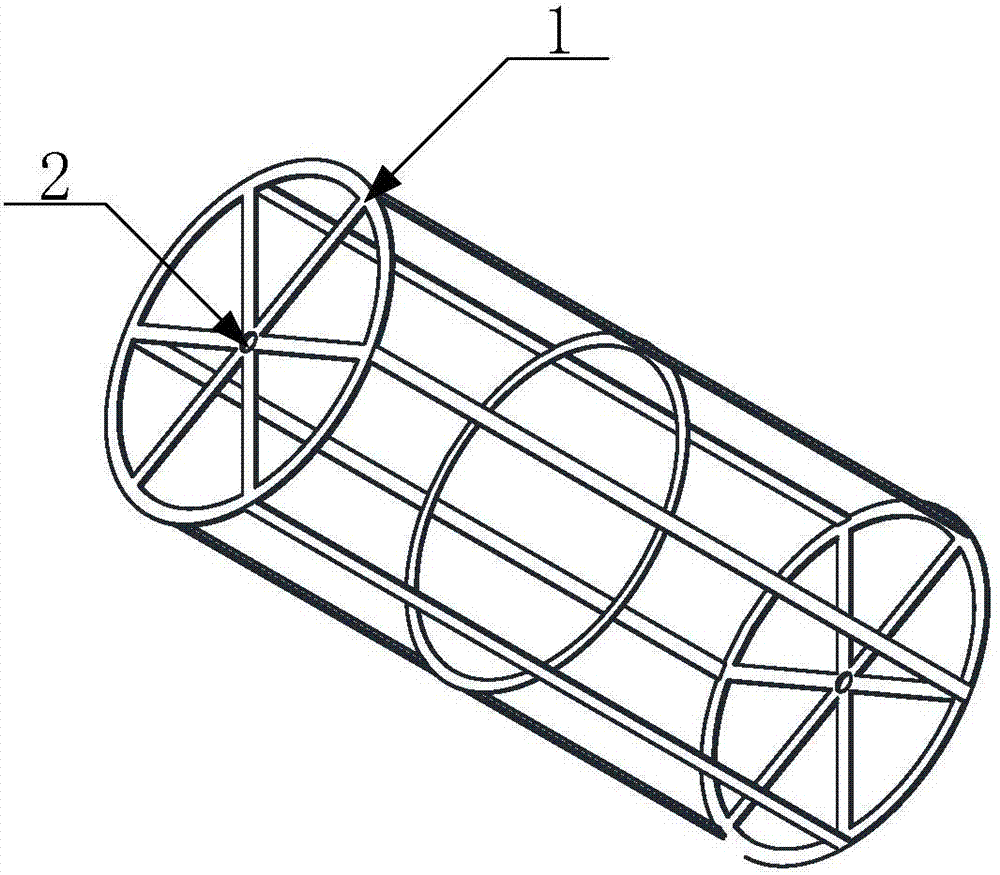

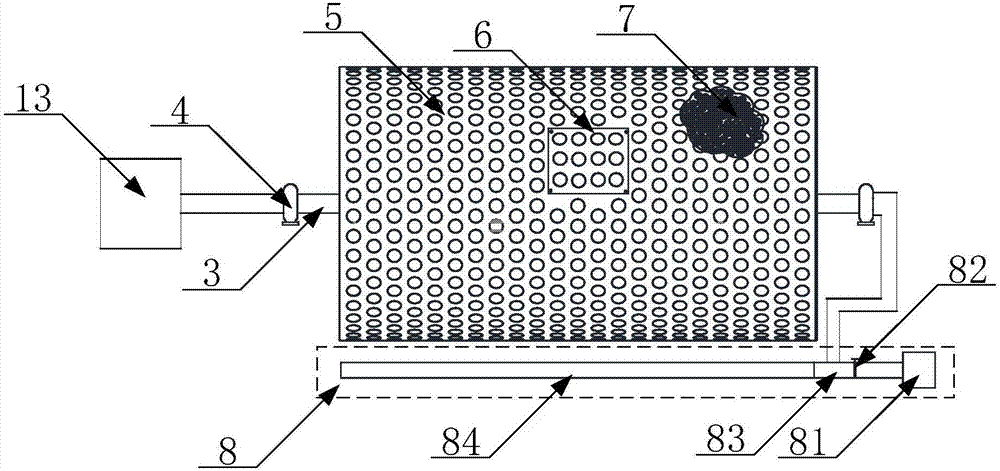

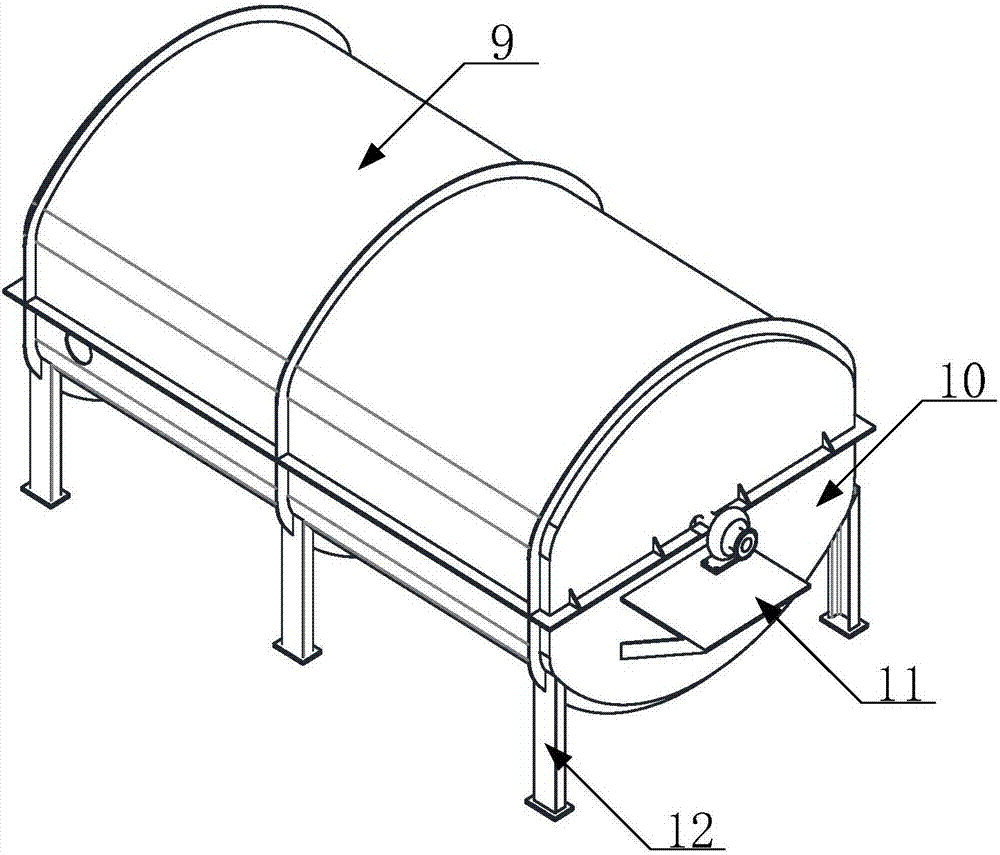

[0030] Such as Figure 1-3 As shown, a kind of fluidized biological drum includes a shell, a drum main body arranged in the shell, and an air blowing system and a driving device 13 connected to the drum main body; The frame 1 is provided with two shaft holes 2 at the center of the two ends of the frame 1, the drum shaft 3 that runs through the two shaft holes 2 and is integrated with the frame 1, and is respectively arranged at two ends of the drum shaft 3. Bearing housing 4, drum outer wall 5 fixed on the side wall of skeleton 1 and both end faces, suspended filler 7 filled in drum outer wall 5, and drum outer wall 5 arranged on the side wall of skeleton 1 and fixed on skeleton 1 Fill the cover with packing on the top 6.

[0031] The framework, the outer wall of the drum and the filling cover are all made of stainless steel, and there are several small holes with a diameter of 5-8mm on the outer wall of the drum and the filling cover; the filling cover can be fixed on the fr...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, except that the suspension filler has at least one attachment wall, and when the number of attachment walls is more than two, all attachment walls are arranged coaxially.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com