Crystalline forms of ferric maltol

A technology of ferric maltol and crystallization, which is applied in the field of new polymorphs of compounds, can solve problems such as no identification or research of polymorphs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

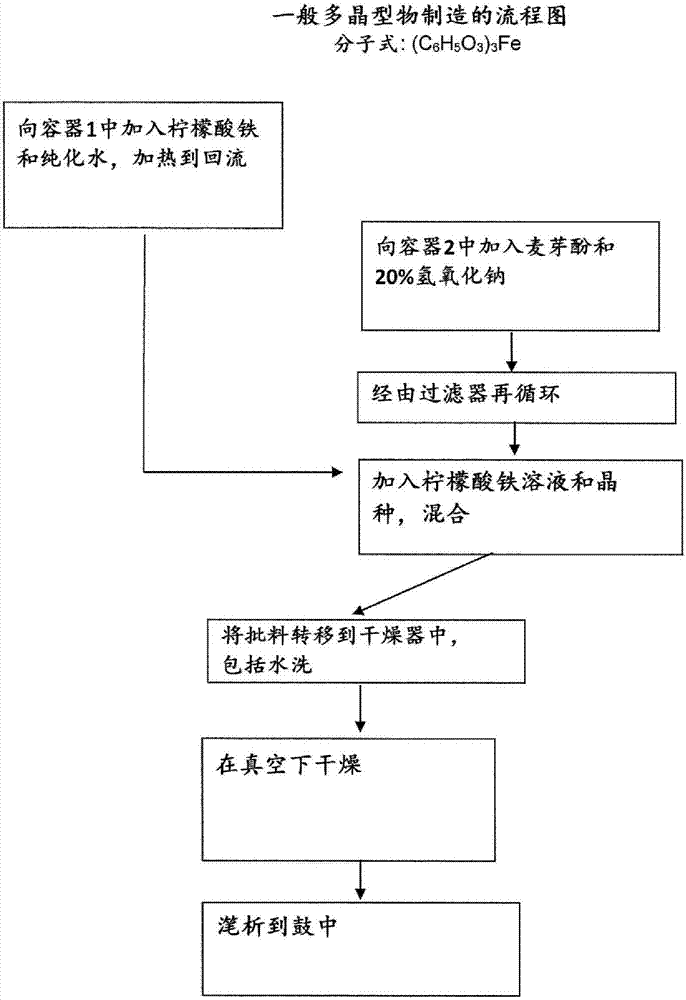

Method used

Image

Examples

Embodiment 1

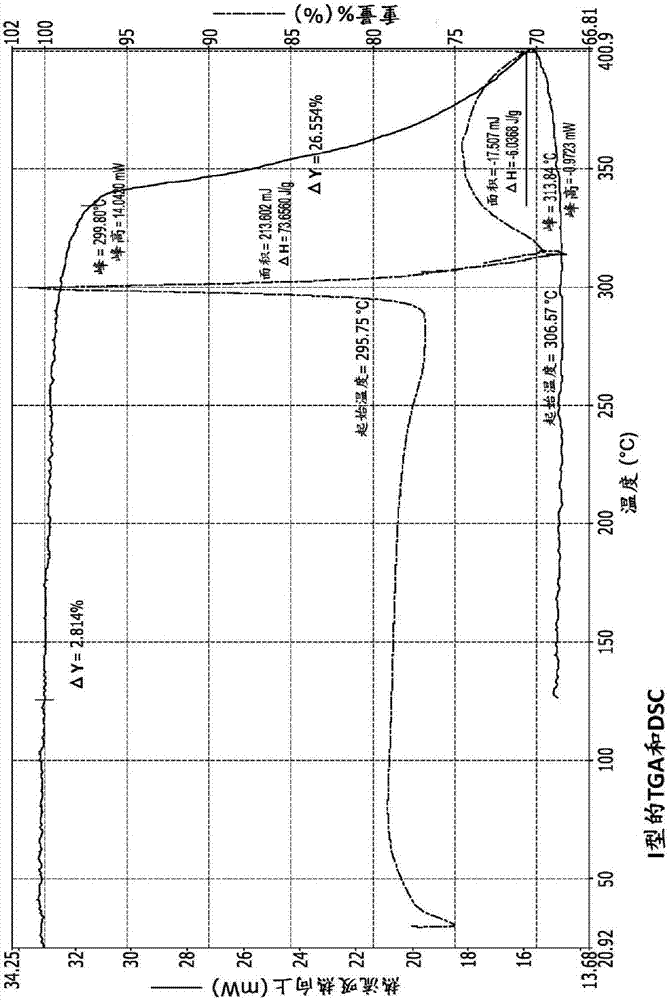

[0190] Example 1: Type I

[0191] Combine 9.04 kg of ferric citrate with 29 liters of purified water. Separately, 12.2 kg of maltol were combined with 15.2 liters of sodium hydroxide solution (20% w / w). Put ferric citrate and sodium hydroxide into a container, add 4 liters of water, and then stir at 20°C to 25°C. Then add seed crystals. The seed crystals are 65 g of iron maltol polymorph in 12 liters of water. The seed crystal was prepared by the same method as that described in Example 1, but the seed crystal was not used. Add seed crystals to the container to help consistent crystallization / precipitation. The mixture was kept in the form of a suspension in a container to allow crystal growth, then filtered and washed three times, using 13 liters of water each time. The resulting solid was dried below 80°C and yielded 13.25 kg of dry maltol iron.

[0192] The ferric maltol in Example 1 was produced on a scale of 12 kg to 15 kg in different batches. Analysis of the ferrous ...

Embodiment 1a

[0194] Production of iron maltol via recrystallization with and without type II inoculation

[0195] Ferric citrate (15g, 6.12×10 -2 mol) was dissolved in water (60 ml) and heated under reflux with stirring to aid dissolution. The solution was then cooled to room temperature. In a separate reaction vessel, maltol (19.17g, 0.152mol) was placed in 6M sodium hydroxide (27ml) at room temperature with stirring until the solid was completely dissolved. Then the solution is finely filtered.

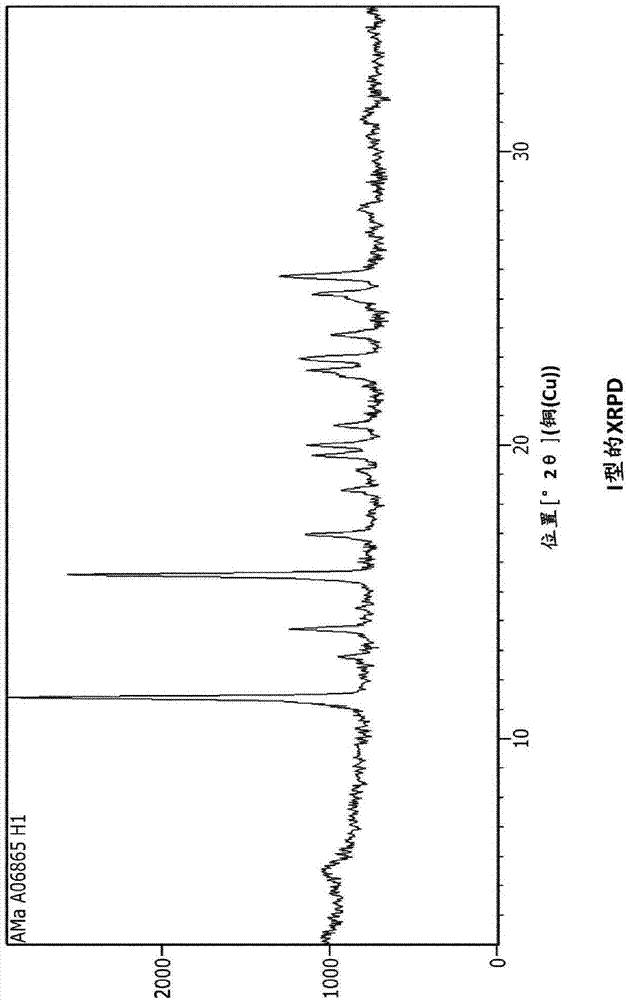

[0196] The ferric citrate solution was added to the sodium maltolate solution under stirring at room temperature. The formation of a precipitate was observed after about 15 minutes. The mixture was sampled after stirring for 2 hours and 4 hours. XRPD analysis shows that the solid is comparable to type I. The slurry was then stirred overnight. The mixture was filtered under suction and most of the solids were dried in a vacuum oven (45°C). A small portion of the solid (3 g) was taken out and dr...

Embodiment 2

[0200] Example 2: Type II

[0201] The general method as described in Example 1 was used to produce the ferric maltol in Example 2, but the ferric maltol was produced in larger batches of 24 kg to 33 kg.

[0202] Analysis of the produced iron maltol showed that the% w / w of iron present was about 12.7% w / w and the% w / w of maltol present was about 88% w / w to 88.6% w / w.

[0203] The XRPD diagram of the type II polymorph obtained from Example 1a is shown in Figure 5 in.

[0204] Analysis of the produced iron maltol showed that in different batches, the% w / w of iron present was about 12.7% w / w to 12.9% w / w and the% w / w of maltol present was about 86.7% w / w to 87.1% w / w. However, the iron maltol seed crystals used in Example 2 are the seed crystals of the type I and type II polymorphs.

[0205] The precipitated ferric maltol was also kept in the wet slurry for a longer time than in Example 1.

[0206] The XRPD diagram of the type II polymorph obtained from Example 1a is shown in Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com