capacity control valve

A capacity control and control channel technology, which is applied in the direction of non-electric variable control, fluid pressure control, control/regulation system, etc., can solve the problems of inability and embedding of the valve stem, reduce leakage, improve foreign body resistance, and improve control speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

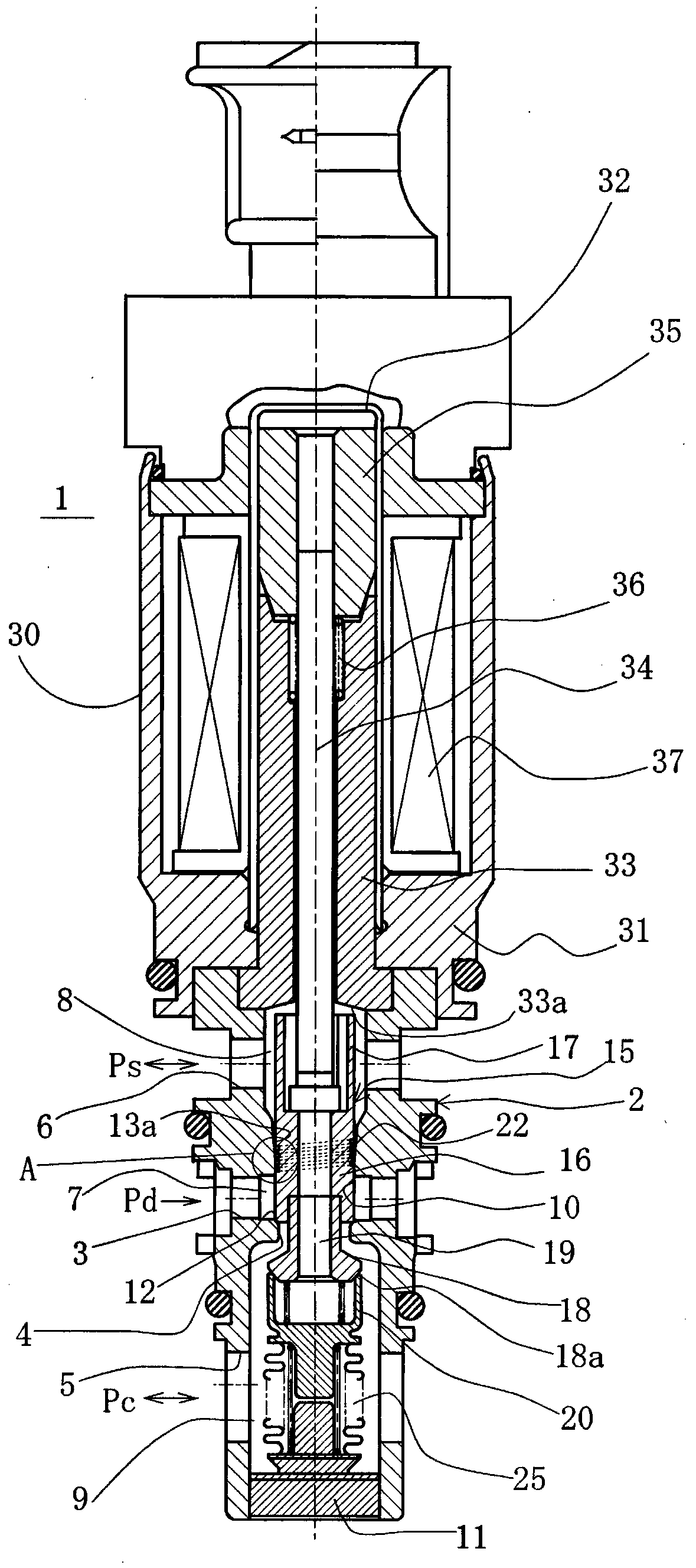

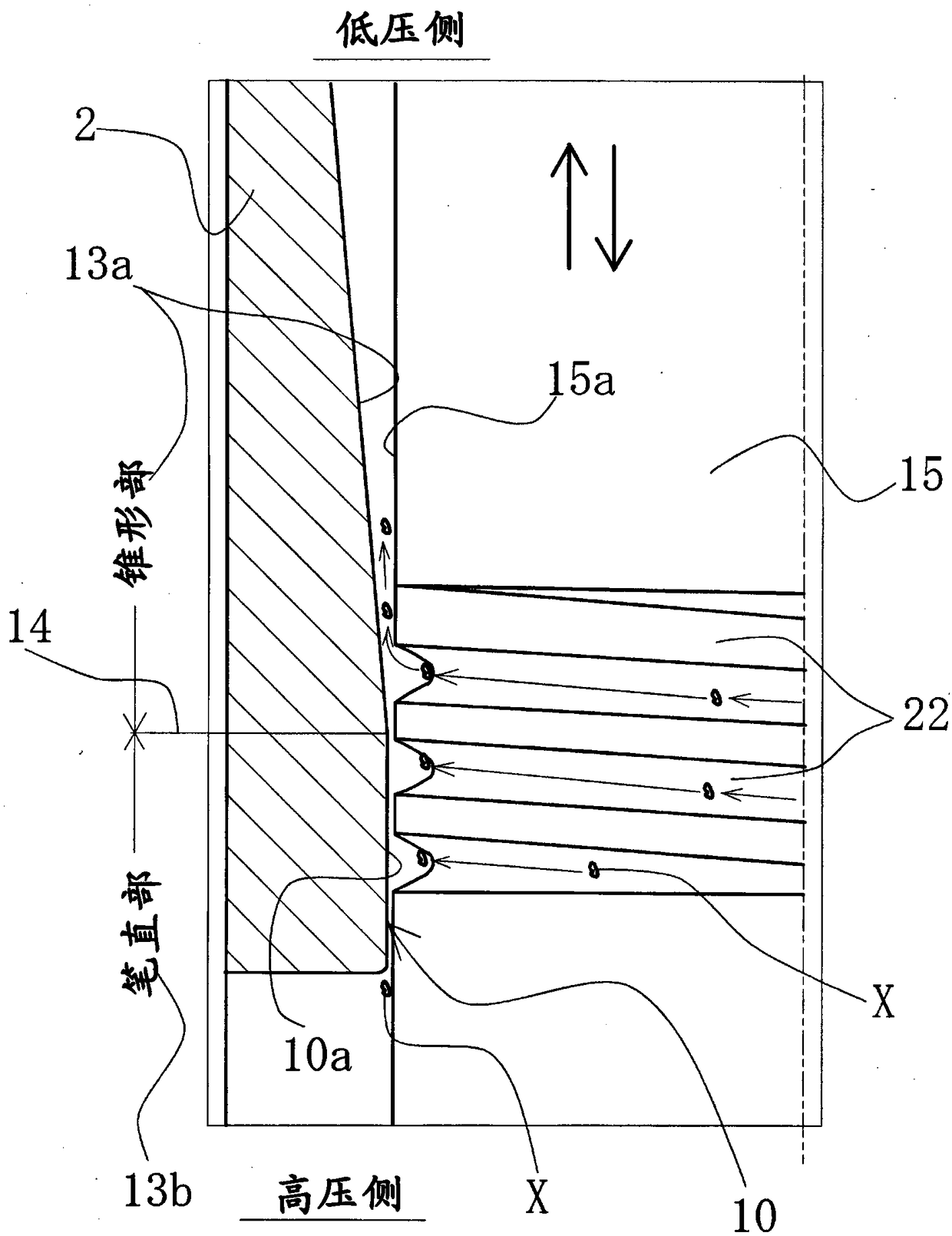

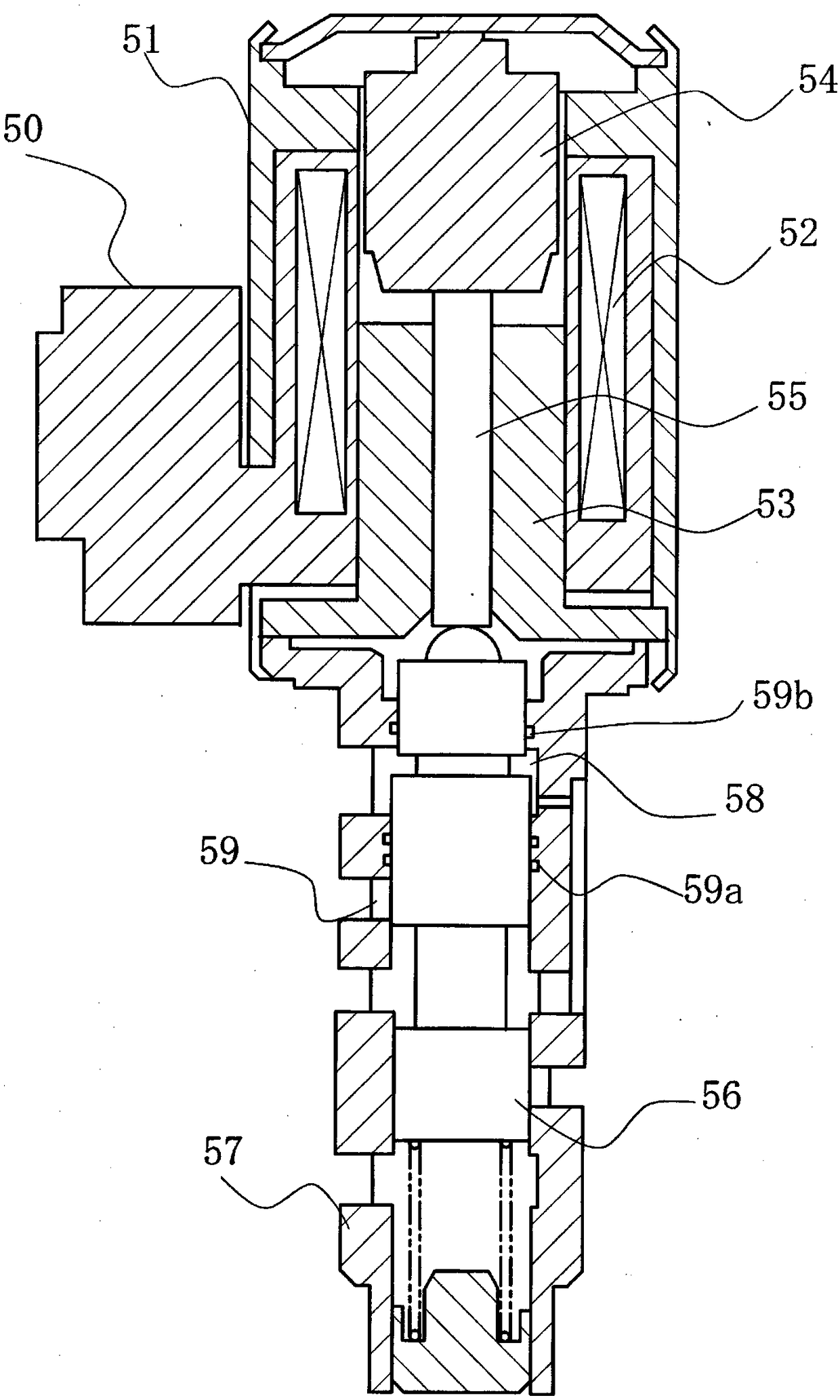

[0032] refer to figure 1 as well as figure 2 , the capacity control valve according to Embodiment 1 of the present invention will be described.

[0033] The capacity control valve 1 includes: a valve case 2 formed of a metal material or a resin material; a valve element 15 disposed in the valve case 2 to reciprocate freely; and a pressure sensitive body 25 that biases the valve element 15 in one direction. and the solenoid 30, etc., which are connected to the valve housing 2 as a driving part for applying an electromagnetic driving force to the spool 15.

[0034] The solenoid 30 includes: a housing 31 connected to the valve housing 2 and formed of a metal material; a sleeve 32 with one end closed; a cylindrical fixed iron core 33 arranged inside the housing 31 and the sleeve 32; The inner side of the fixed iron core 33 is free to reciprocate and the driving rod 34 whose front end is connected with the valve core 15; the movable iron core 35 fixed on the other end side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com