TiO2-carbon fiber composite photocatalyst used for high salinity wastewater organic pollutant treatment and preparation thereof

A technology of organic pollutants and carbon fibers, which is used in physical/chemical process catalysts, catalyst activation/preparation, water pollutants, etc. Adsorption capacity, the effect of promoting adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

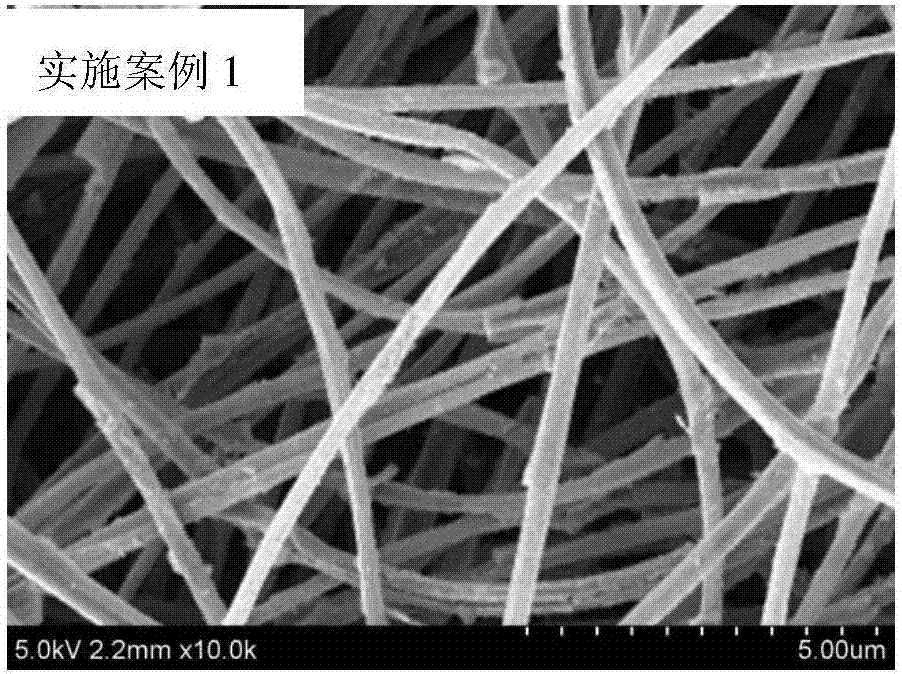

Embodiment 1

[0051] (1) Catalyst preparation

[0052] Take 1.5g of carbon fiber and 200mL of absolute ethanol in a flask, stir and adsorb in a 30°C water bath. Add it to a round bottom flask, and stir in a constant temperature water bath until a uniformly dispersed suspension system is formed and ultrasonically dispersed. Slowly add 5.000g of tetrabutyl titanate into the carbon fiber / absolute ethanol suspension system dropwise. After the dropwise addition, under the action of stirring (300 rpm), raise the temperature of the water bath to 80°C, and slowly add 60mL of deionized Water, with a dropping rate of 3 mL / min, stirred (300 rpm) at 80°C for 5 hours. After the reaction is completed, filter, wash and dry to obtain a powder sample, which is TiO 2 -Carbon fiber composite material.

[0053] 2gTiO 2 - Carbon fiber composite material and 200mL deionized water are added to a high-pressure reactor lined with polytetrafluoroethylene, sealed and placed in a blast drying oven for heat treatme...

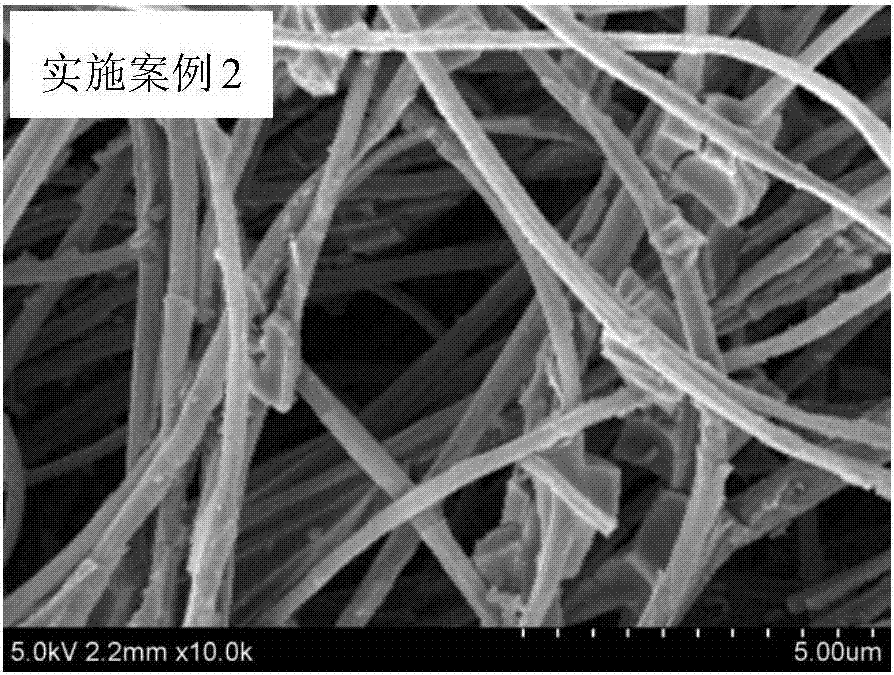

Embodiment 2

[0064] (1) Catalyst preparation

[0065] Take 1.5g of carbon fiber and 200mL of absolute ethanol in a flask, stir and adsorb in a 30°C water bath. Add it to a round bottom flask, and stir in a constant temperature water bath until a uniformly dispersed suspension system is formed and ultrasonically dispersed. Slowly add 10.000g of tetrabutyl titanate into the carbon fiber / absolute ethanol suspension system dropwise. After the dropwise addition, under stirring, raise the temperature of the water bath to 80°C, and slowly add 60mL of deionized water at a rate of 3 mL / min, the reaction was stirred at 80°C for 5 hours. After the reaction is completed, filter, wash and dry to obtain a powder sample, which is TiO 2 -Carbon fiber composite material.

[0066] 2g TiO 2 - Carbon fiber composite material and 200mL deionized water are added to a high-pressure reactor lined with polytetrafluoroethylene, sealed and placed in a blast drying oven for heat treatment at 170°C for 12 hours. ...

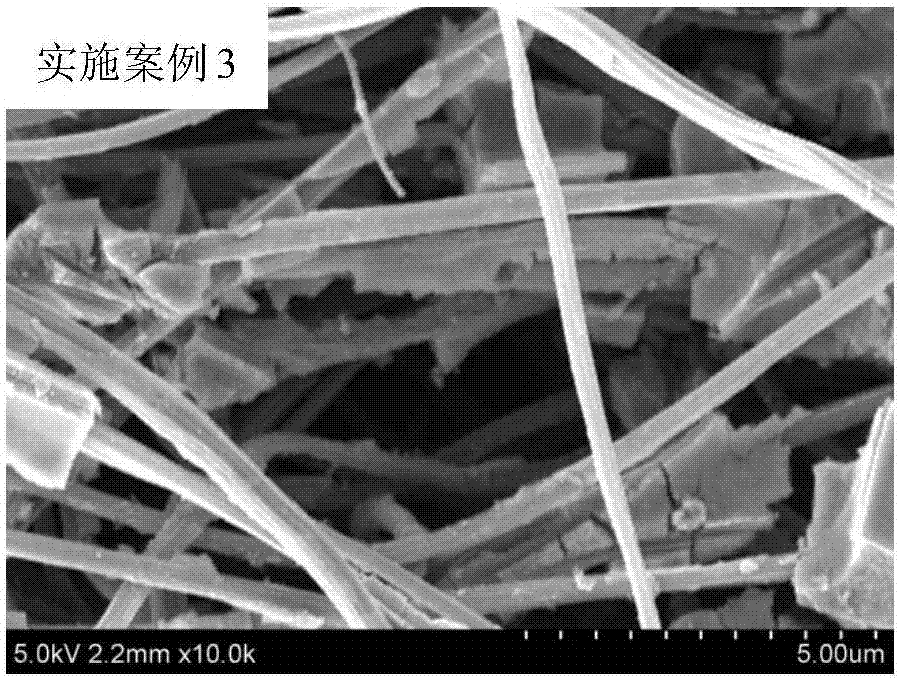

Embodiment 3

[0077] (1) Catalyst preparation

[0078] Take 1.5g of carbon fiber and 200mL of absolute ethanol in a flask, stir and adsorb in a 30°C water bath. Add it to a round bottom flask, and stir in a constant temperature water bath until a uniformly dispersed suspension system is formed and ultrasonically dispersed. Slowly add 15.000g of tetrabutyl titanate to the carbon fiber / absolute ethanol suspension system dropwise. After the dropwise addition, under stirring, raise the temperature of the water bath to 80°C, and slowly add 60mL of deionized water at a rate of 3 mL / min, the reaction was stirred at 80°C for 5 hours. After the reaction is completed, filter, wash and dry to obtain a powder sample, which is TiO 2 -Carbon fiber composite material.

[0079] 2g TiO 2 - Carbon fiber composite material and 200mL deionized water are added to a high-pressure reactor lined with polytetrafluoroethylene, sealed and placed in a blast drying oven for heat treatment at 170°C for 12 hours. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com