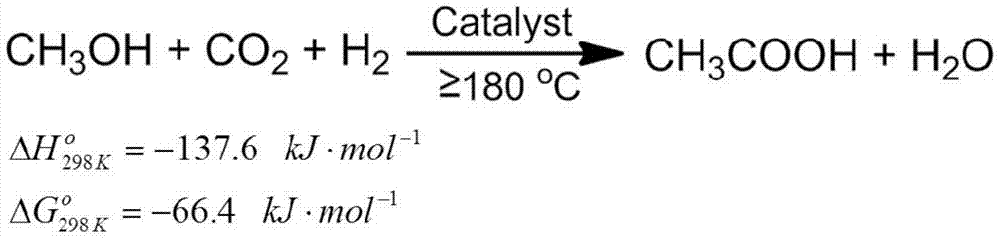

Method for synthesizing acetic acid by methanol, carbon dioxide and hydrogen gas

A catalyst and iodide technology, applied in the field of synthesizing acetic acid, can solve the problems such as expensive raw material of methyl iodide, low activity and selectivity, high toxicity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, catalytic methanol, carbon dioxide and hydrogen synthesis acetic acid:

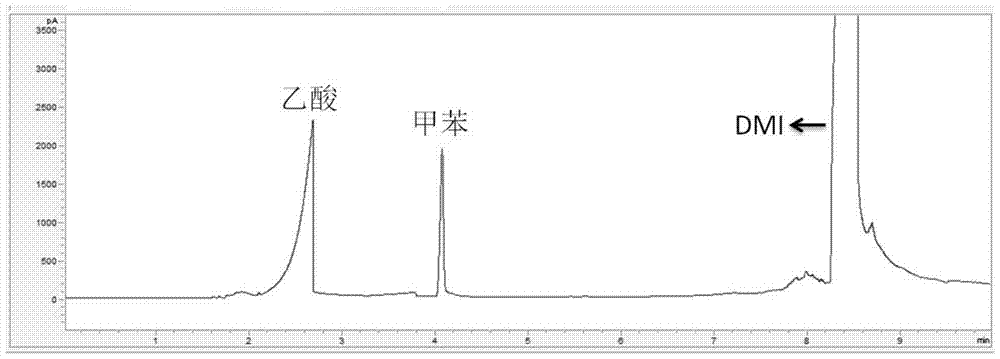

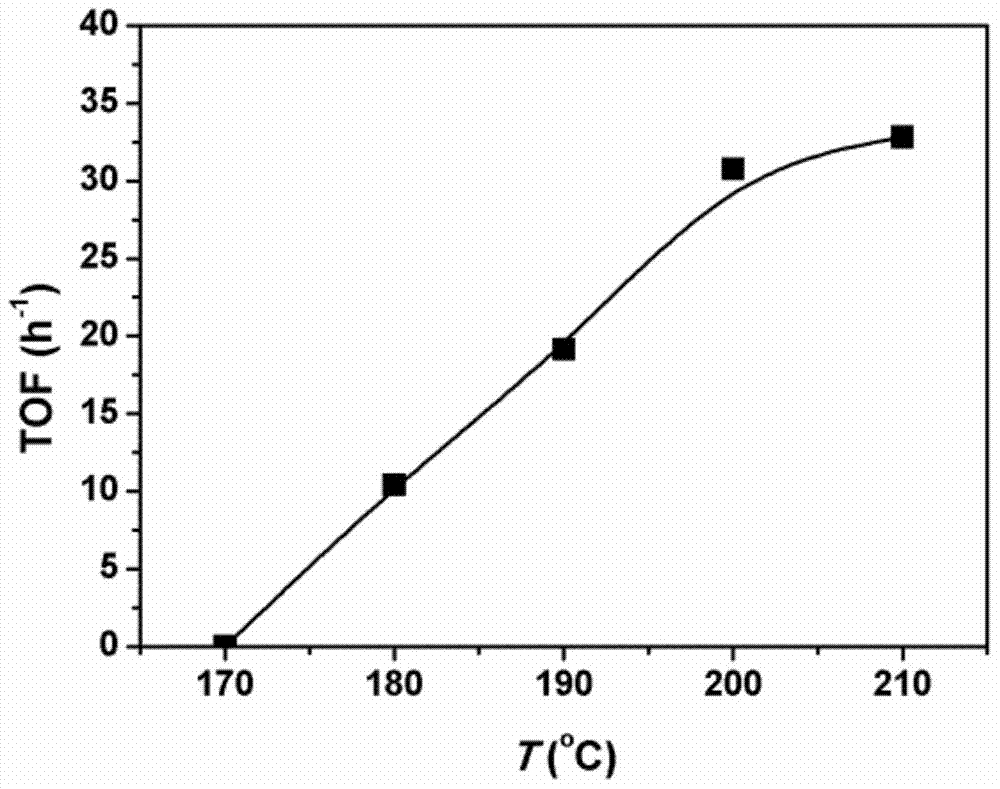

[0042]The ruthenium complex and the rhodium complex catalyst, organic ligand, iodide promoter, methanol and solvent are added to a stainless steel reactor (magnetic sub with built-in electromagnetic stirring) with a volume of 16mL, and the reaction The still is sealed and replaced twice with 1MPa carbon dioxide gas. At room temperature, carbon dioxide and hydrogen are respectively charged into the reaction kettle, and the reaction kettle is placed in a heating furnace at a constant temperature, and the electromagnetic stirrer is set to 800 rpm. points, react. After the reaction, the reactor was placed in an ice-water bath, and the gas was released after cooling. Wherein, liquid products and gas products were analyzed by gas chromatography.

[0043] Concrete reaction conditions are as follows: ruthenium complex catalyst 20mmol / L, rhodium complex catalyst 20mmol / L (the amount of ruthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com