Method for preparing efficient environmental-friendly universal magnesium silicate coating mist polycoagulant

A paint mist coagulant, magnesium lithium silicate technology, which is applied in the direction of flocculation/precipitated water/sewage treatment, waste paint treatment, etc. Excellent paint mist removal effect, simple use method and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

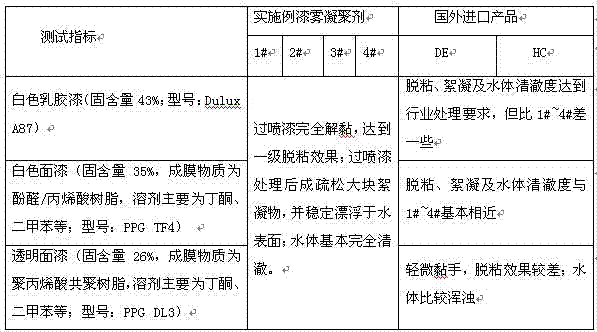

Examples

Embodiment 1

[0027] 1) Mix 100 parts of lithium magnesium silicate and 5 parts of hexadecyltrimethylammonium bromide with water to make a hectorite aqueous dispersion with a solid content of 15%, then add 5 parts of iron nitrate, stir and mix After uniformity, add sodium carbonate solution dropwise until the pH of the aqueous solution is ≥ 12;

[0028] 2) Then add 0.5 part of sodium carboxymethyl cellulose to the above solution, stir and mix evenly, then add 0.1 part of cationic polyacrylamide, and then make a high-efficiency general-purpose lithium magnesium silicate paint mist coagulant 1# .

Embodiment 2

[0030] 1) Mix 100 parts of lithium magnesium silicate, 3 parts of cetyltrimethylammonium bromide, and 3 parts of cetyltrimethylammonium chloride, and mix them with water to make laponite with a solid content of 20%. Water dispersion, add 4 parts of ferric nitrate and 2 parts of ferric sulfate, stir and mix evenly, add sodium carbonate solution dropwise until the pH of the aqueous solution is ≥ 12;

[0031] 2) Then add 0.5 parts of sodium carboxymethyl cellulose and 0.5 parts of sodium alginate to the above solution, stir and mix evenly, then add 0.2 parts of cationic polyacrylamide, and then make a high-efficiency general-purpose lithium magnesium silicate after fully stirring Paint mist coagulant 2#.

Embodiment 3

[0033] 1) Mix 100 parts of lithium magnesium silicate, 3 parts of cetyltrimethylammonium bromide, 3 parts of cetyltrimethylammonium chloride and 2 parts of dodecyltrimethylammonium bromide And use water to make a hectorite aqueous dispersion with a solid content of 25%, then add 4 parts of ferric nitrate, 2 parts of ferric sulfate and 2 parts of ferric chloride, stir and mix well, then add sodium carbonate solution dropwise until the pH of the aqueous solution≥ 12;

[0034] 2) Then add 1 part of sodium carboxymethyl cellulose, 1 part of sodium alginate and 1 part of sodium polyacrylate to the above solution, stir and mix evenly, then add 0.3 part of cationic polyacrylamide, and then obtain high-efficiency General-purpose lithium magnesium silicate paint mist coagulant 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com