Organic wastewater biological treatment process of industrial waste lye

A technology for organic wastewater and biological treatment, which is applied in aerobic process treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of high treatment cost, extremely high boundary conditions, and pollutant transfer. , to achieve the effect of reducing treatment costs, good economic benefits, and increasing effluent indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

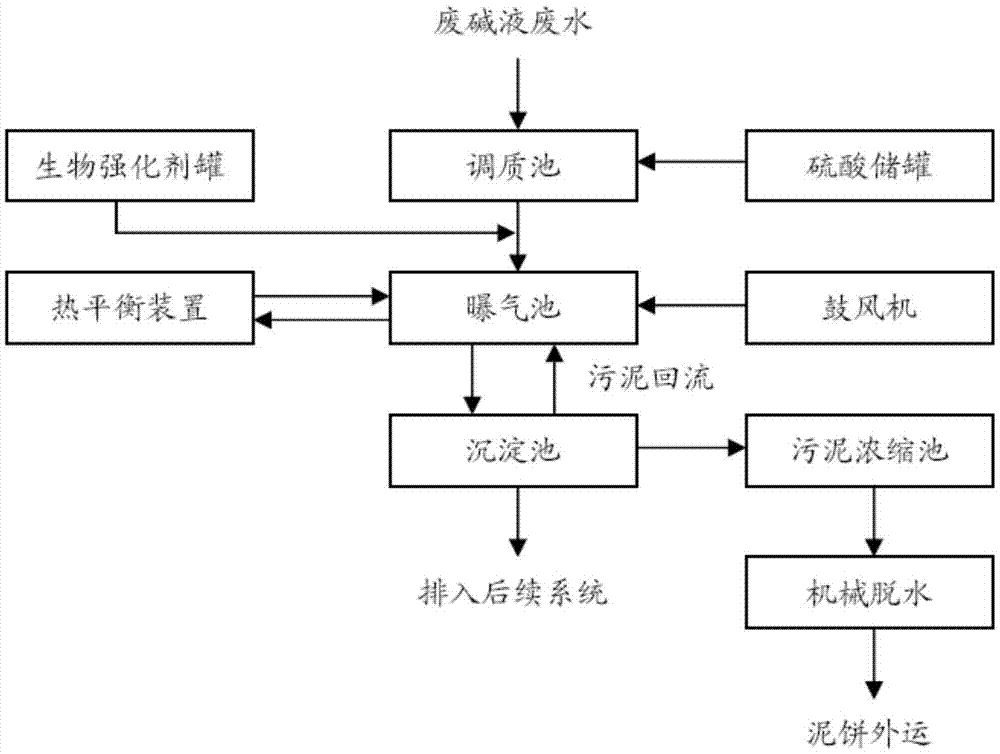

[0030] The high-concentration waste lye organic wastewater enters the conditioning tank through the wastewater lifting pump. At this time, the pH value of the wastewater is between 12 and 14. The process of the present invention requires a pH value between 6.5 and 7.5, which needs to be transferred from the acid storage tank to the conditioning tank The mass pool is pumped into sulfuric acid for neutralization. Since a large amount of sodium hydroxide (NaOH) is used in the alkaline washing process, the wastewater is strongly alkaline, and the pH value of the wastewater is generally around 12 to 14. The wastewater must be treated before entering the biochemical treatment system. Neutralization treatment, select sulfuric acid as neutralizing agent in the technological process of the present invention, the sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com