Green algae polysaccharide and preparation method thereof

A technology of chlorophyll polysaccharides and sulfated polysaccharides, applied in the field of marine biological polysaccharides, can solve the problems of chlorophyll polysaccharide structure complexity, inhomogeneity, and restrictions on in-depth research, and achieve obvious anticoagulant activity, no toxic side effects, and good market application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a preparation method of Chlorella polysaccharide, said method comprising the steps of:

[0054] (1) adding water to the dry bag reef film to form a homogenate, extracting at 20°C-24°C for 0.5-4 hours, and separating the clear liquid; wherein, the quality of the water is 10-60 times that of the bag reef film;

[0055] (2) concentrating and desalting the obtained clear liquid under reduced pressure to obtain a first polysaccharide solution, concentrating and drying the first polysaccharide solution under reduced pressure to obtain a polysaccharide, and dissolving the polysaccharide in water to obtain a second polysaccharide solution, the The mass fraction of the polysaccharide in the second polysaccharide solution is 0.1%-6%;

[0056] (3) The second polysaccharide solution is separated by ion-exchange chromatographic column and gel chromatographic column, then concentrated under reduced pressure and desalted, and the desalted solution i...

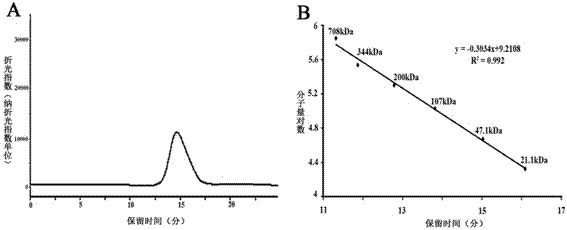

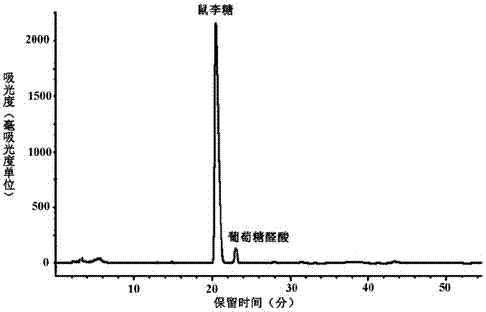

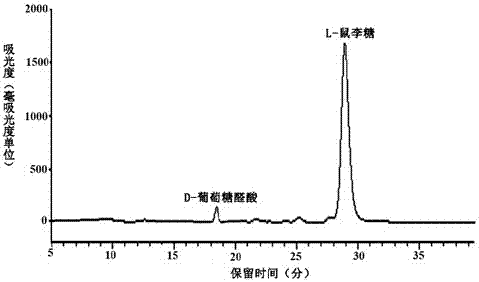

Embodiment 1

[0063] (1) Add 1500 grams of water to 50 grams of dry bag reef film to soak to form a homogenate, stir and extract at 21°C for 3.0 hours, centrifuge to discard the precipitate, and separate the supernatant;

[0064] (2) concentrating the resulting clear liquid under reduced pressure, and dialysis and desalination to obtain the first polysaccharide solution. The step of dialysis and desalination includes: placing the clear liquid concentrated under reduced pressure in a dialysis bag with a molecular weight cut-off of 3500 Daltons for dialysis for 3 days , stop dialysis when the conductivity meter tests the external fluid to a constant value after dialysis;

[0065] Concentrate the first polysaccharide solution under reduced pressure, add ethanol with a mass fraction of 95% to the concentrated first polysaccharide solution to precipitate the polysaccharide, the volume of ethanol is four times the volume of the first polysaccharide solution, and place the resulting precipitate at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com