A kind of preparation technology of biological white charcoal

A preparation process, biochar technology, applied in the field of agricultural resources and environment, can solve the problems of ineffective reduction of heavy metal content, reduction of migration and bioavailability, contamination of operator's clothes, etc., to reduce the content of heavy metals and organic pollutants, Improve the practical value and avoid the effect of staining clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

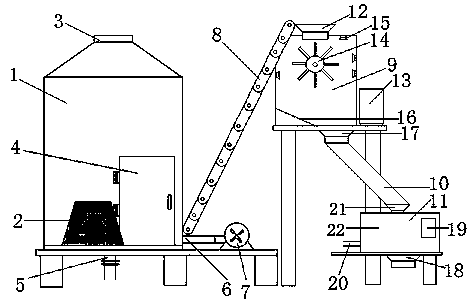

[0032] The preparation technology of a kind of biological white charcoal that the present invention proposes comprises the following steps:

[0033] Step 1. Raw material pretreatment: Cut the biomass raw material into small pieces and perform cleaning pretreatment; then put the biomass raw material into the catalyst solution with a mass fraction of 5-15%, stir, soak and filter to obtain water and catalyst The biomass raw material; the catalyst solution is a mixed solution composed of manganese dioxide solution, ferric chloride solution, aluminum oxide solution, sodium carbonate solution and rare earth elements in any volume ratio;

[0034] Step 2, initial drying: the biomass raw material obtained in step 1 is placed in a dryer for initial drying, and the temperature of the dryer is controlled at 100-120°C so that the moisture content is lower than 15%;

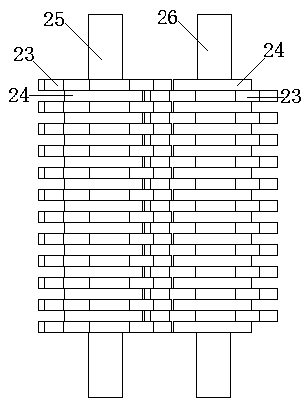

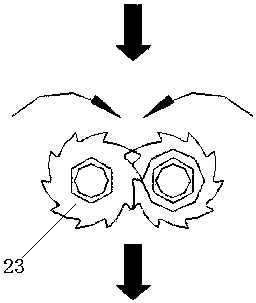

[0035] Step 3, pulverization: put the biomass raw material that has been dried for the first time into a pulverizer for pulv...

Embodiment 1

[0047] The preparation technology of biological white charcoal provided by the present invention comprises the following steps:

[0048] Step 1. Raw material pretreatment: Cut the biomass raw material into small pieces and perform cleaning pretreatment; then put the biomass raw material into the catalyst solution with a mass fraction of 10%, stir, soak and filter to obtain the raw material containing water and catalyst. Material raw materials; the catalyst solution is a mixed solution composed of manganese dioxide solution, ferric chloride solution, aluminum oxide solution, sodium carbonate solution and rare earth elements in a volume ratio of 2:2:2:2:1;

[0049] Step 2, initial drying: the biomass raw material obtained in step 1 is placed in a dryer for initial drying, and the temperature of the dryer is controlled at 100°C so that the moisture content is lower than 15%;

[0050] Step 3, pulverization: Put the biomass raw material that has been dried for the first time into a...

Embodiment 2

[0058] A preparation process of biological white charcoal, comprising the following steps:

[0059] Step 1. Raw material pretreatment: cut the biomass raw material into small pieces and perform cleaning pretreatment; then put the biomass raw material into the catalyst solution with a mass fraction of 15%, stir, soak and filter to obtain the raw material containing water and catalyst. Material raw materials; catalyst solution is a mixed solution formed by mixing manganese dioxide solution, ferric chloride solution, aluminum oxide solution, sodium carbonate solution and rare earth elements in a volume ratio of 2:1:1:1:1;

[0060] Step 2, initial drying: the biomass raw material obtained in step 1 is placed in a dryer for initial drying, and the temperature of the dryer is controlled at 110°C so that the moisture content is lower than 15%;

[0061] Step 3, crushing: Put the biomass raw material that has been dried for the first time into a pulverizer for pulverization, the speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com