Process of extracting arsenic from arsenic sulfide waste residue by adopting whole wet method

An arsenic sulfide, all-wet technology, applied in the field of arsenic sulfide waste residue treatment, can solve the problems of short process flow, reduce the use cost, improve the recovery effect, and solve the problem of acid expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

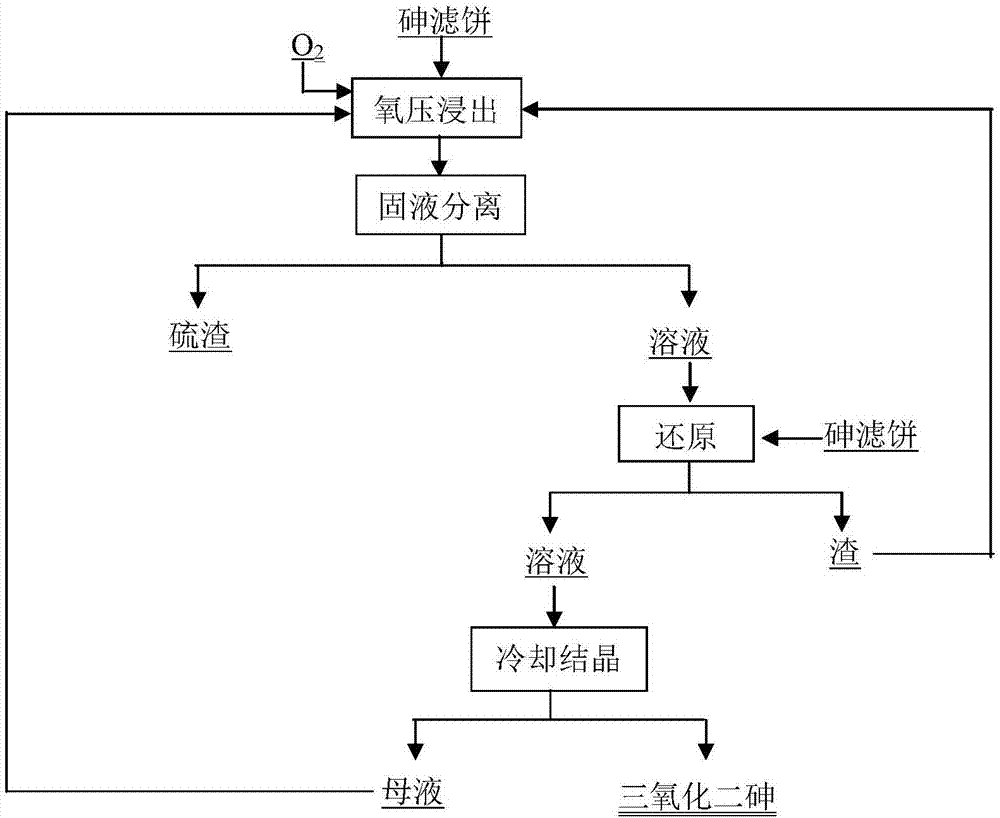

[0033] according to figure 1 Process steps, take 100g of arsenic filter cake, add oxygen leaching solution (containing H 2 SO 4 80g / L, pentavalent arsenic 20g / L) 500mL, its liquid-solid ratio is 5L: 1kg, the reaction temperature is 85 ℃, mechanical stirring, the reaction is 1 hour, hot filtration, the solution is cooled to 10 ℃, can obtain As-containing 2 O 3 Up to 99.3% of arsenic trioxide solid, the reduction rate of pentavalent arsenic in the reduction process is 92.6%.

Embodiment 2

[0035] according to figure 1 Process step, get 50g of arsenic filter cake, add oxygen leaching solution (containing H 2 SO 4 100g / L, pentavalent arsenic 30g / L) 500mL, its liquid-solid ratio is 10L: 1kg, the reaction temperature is 90 ℃, mechanical stirring, the reaction is 0.5 hours, hot filtration, the leachate is cooled to 25 ℃, and the As-containing 2 O 3 Up to 99.2% of arsenic trioxide solid, the reduction rate of pentavalent arsenic in the reduction process is 96.3%.

Embodiment 3

[0037] according to figure 1 Process steps, take 160g of arsenic filter cake, add oxygen leaching solution (containing H 2 SO 4 160g / L, pentavalent arsenic 20g / L) 1000mL, its liquid-solid ratio is 25L: 4kg, the reaction temperature is 100 ℃, mechanical stirring, the reaction is 0.5 hours, hot filtration, cooled to 25 ℃, can obtain As-containing2 O 3 Up to 99.1% of arsenic trioxide solid, the reduction rate of pentavalent arsenic in the reduction process is 97.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com