Carbon nanofiber loaded nickel-based catalytic material containing zinc oxide and preparation method thereof

A technology of nano-carbon fiber and catalytic materials, which is applied in the field of hydrogenation, can solve problems affecting product selection performance, etc., and achieve the effects of easy regulation, improved catalytic selectivity, and difficult aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

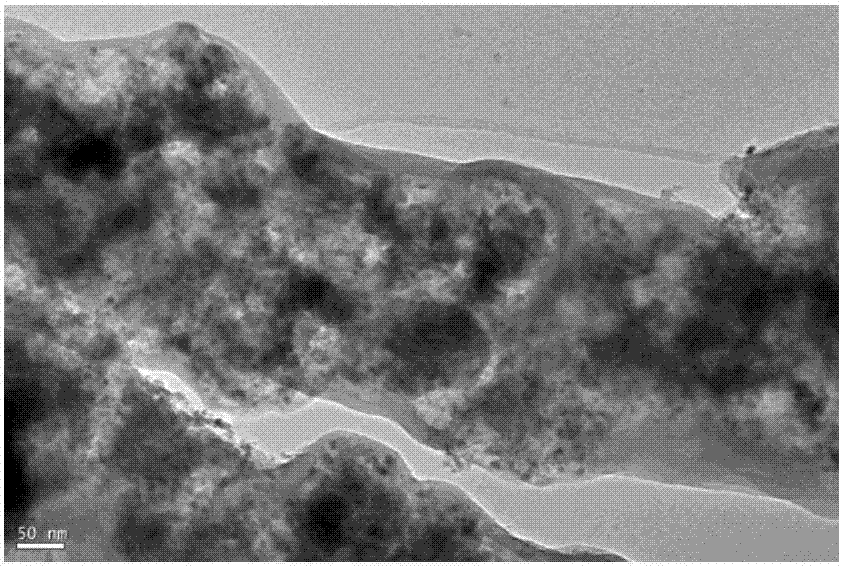

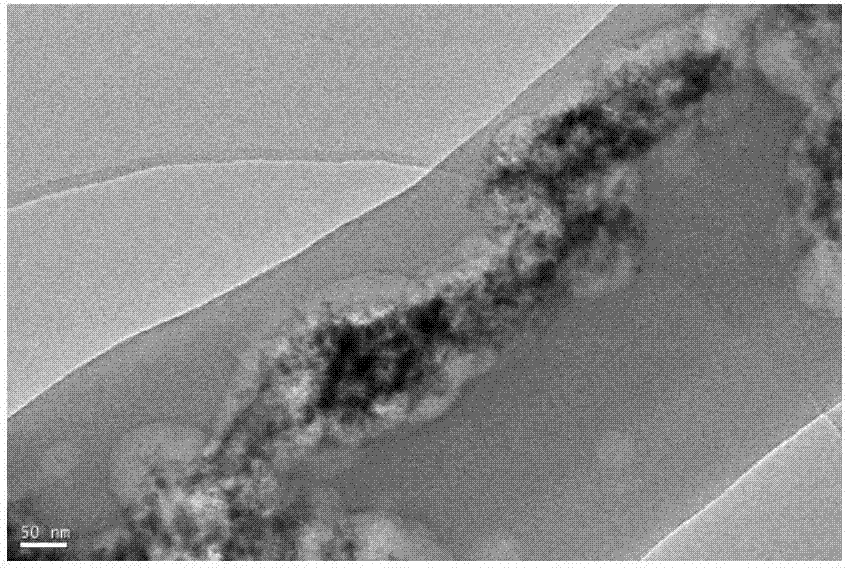

Image

Examples

Embodiment 1

[0029] A zinc oxide-containing nano-carbon fiber-loaded nickel-based catalytic material comprises the following raw materials in weight percentages: calculated as oxides, 48% of zinc oxide, 44% of nickel oxide, and 8% of carbon fiber.

[0030] Its preparation method comprises the following steps:

[0031] (1) Preparation of zinc-nickel bimetallic organic framework materials:

[0032] (a) dissolving zinc nitrate and nickel nitrate in N-N dimethylformamide with a molar ratio of 1.8:1 to form a solution containing zinc and nickel;

[0033] (b) dissolving terephthalic acid in N-N dimethylformamide to form a terephthalic acid solution;

[0034] (c) Add the zinc-nickel solution dropwise to the terephthalic acid solution under stirring conditions, and continue stirring for 0.5h after the dropwise addition is completed to generate the product;

[0035] (d) Suction filtration and washing were repeated for 3 times on the generated product, and vacuum drying was obtained.

[0036] (2)...

Embodiment 2

[0041] A zinc oxide-containing nano-carbon fiber-loaded nickel-based catalytic material comprises the following raw materials in weight percentage: calculated as oxides, 38% of zinc oxide, 45% of nickel oxide, and 17% of carbon fiber.

[0042] Its preparation method comprises the following steps:

[0043] (1) Preparation of zinc-nickel bimetallic organic framework materials:

[0044] (a) Zinc acetate and nickel acetate are dissolved in N-N dimethylformamide at a molar ratio of 1.5:1 to form a solution containing zinc and nickel;

[0045] (b) dissolving terephthalic acid in N-N dimethylformamide to form a terephthalic acid solution;

[0046] (c) Add the zinc-nickel solution dropwise to the terephthalic acid solution under stirring conditions, and continue stirring for 1 hour after the dropwise addition is completed to generate the product;

[0047] (d) Repeat suction filtration and washing for 5 times to the generated product, and vacuum dry to obtain the final product.

[0...

Embodiment 3

[0053] A zinc oxide-containing nano-carbon fiber-loaded nickel-based catalytic material includes the following raw materials in weight percentages: calculated as oxides, 28% of zinc oxide, 46% of nickel oxide, and 26% of carbon fiber.

[0054] Its preparation method comprises the following steps:

[0055] (1) Preparation of zinc-nickel bimetallic organic framework materials:

[0056] (a) zinc carbonate and basic nickel carbonate are dissolved in N-N dimethylformamide at a molar ratio of 2.5:1 to form a solution containing zinc and nickel;

[0057] (b) dissolving terephthalic acid in N-N dimethylformamide to form a terephthalic acid solution;

[0058] (c) Add the zinc-nickel solution dropwise to the terephthalic acid solution under stirring conditions, and continue stirring for 0.5h after the dropwise addition is completed to generate the product;

[0059] (d) Suction filtration and washing were repeated twice for the generated product, and vacuum drying was obtained.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com