Method of preparing light ceramisite by use of muck

A lightweight ceramsite and slag technology, applied in clay products, applications, household appliances, etc., can solve the problems of occupying land resources, high production process, polluting the environment, etc., to reduce sintering temperature, improve strength, and increase light weight. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 60 parts by weight of construction site waste slag, 20 parts by weight of carbonized rice husk ash, and 20 parts by weight of fly ash, mix and ball mill until the particle size is less than 100 microns to obtain batch materials, and put the ingredients into a ball-forming disc to granulate into balls and atomize Spray 20 parts by weight of 5% sodium bicarbonate solution to prepare a spherical material ball of 5-20mm, put the material ball into a container and microwave it to heat up to 1200°C, keep it warm for 10 minutes, and take it out after naturally cooling to room temperature.

Embodiment 2

[0029] Weigh 70 parts by weight of construction site waste slag, 10 parts by weight of carbonized rice husk ash, and 20 parts by weight of fly ash, mix and ball mill until the particle size is less than 100 microns to obtain batch materials, put the ingredients into a ball-forming disc, granulate into balls and atomize Spray 18 parts by weight of 3% sodium bicarbonate solution to prepare a spherical material ball of 5-20mm, put the material ball into a container and microwave to heat up to 800°C, keep it warm for 30 minutes, and take it out after naturally cooling to room temperature.

Embodiment 3

[0031] Weigh 80 parts by weight of construction site waste slag, 10 parts by weight of carbonized rice husk ash, and 10 parts by weight of fly ash, mix and ball mill until the particle size is less than 100 microns to obtain batch materials, and put the ingredients into a ball-forming disc to granulate into balls and atomize Spray 10 parts by weight of 6% sodium bicarbonate solution to prepare spherical material balls of 5-20 mm in size, put the material balls into a container and microwave to heat up to 1100° C., keep warm for 15 minutes, and take out after naturally cooling to room temperature.

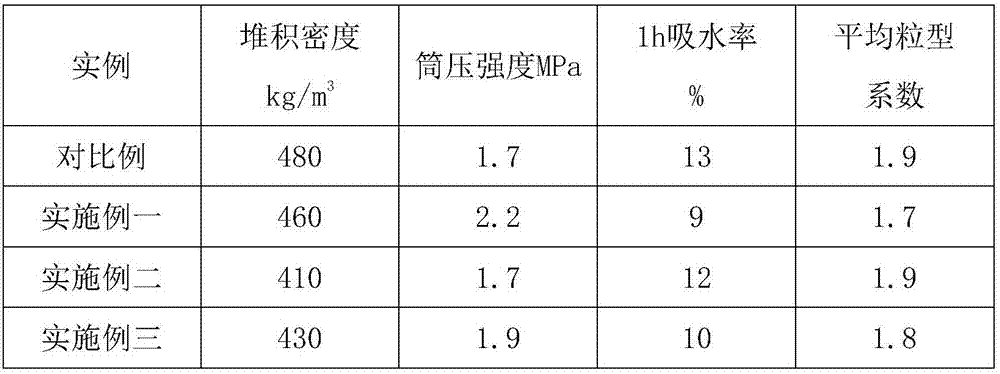

[0032] The performance evaluation indicators of slag ceramsite are in accordance with "GB / T17431-2010 Lightweight Aggregate and Its Test Methods", "JC487-1992 Ultralight Ceramsite and Pottery Sand".

[0033] The comparison of specific performance indicators between the lightweight slag ceramsite obtained in Examples 1-3 of the present invention and ordinary ceramsite (ie comparative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com