Preparation method of graphene/silicon dioxide/rubber composite material

A technology of silica and composite materials, applied in the field of nanocomposite materials, can solve the problems of difficult dispersion and easy agglomeration of graphene and silica, and achieve the effects of low density, high specific surface area and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

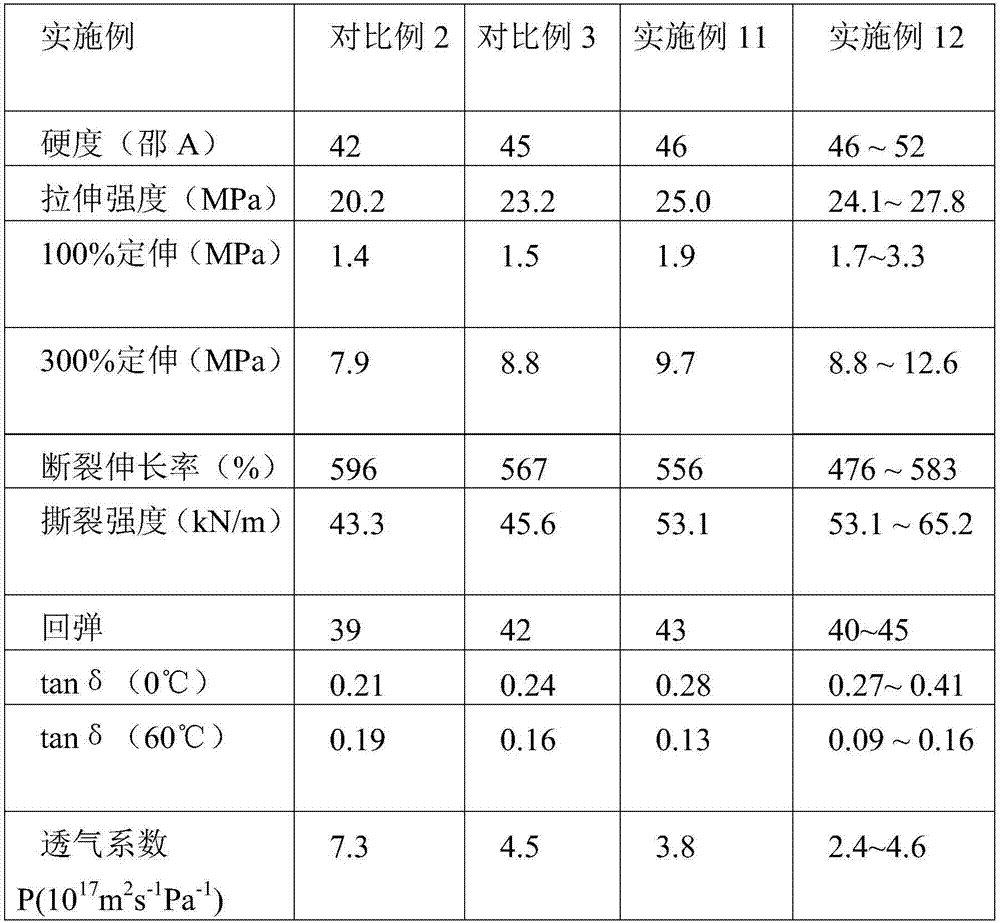

Examples

Embodiment 1

[0023] (1) Mix graphene oxide with water to obtain a graphene oxide solution, put it in an ultrasonic instrument for further ultrasonic dispersion, the ultrasonic frequency is 1000HZ, the temperature is 25°C, the ultrasonic time is 0.5h, and the obtained concentration is 1mg / ml Graphene oxide solution;

[0024] (2) Mix ethyl orthosilicate and ethanol at a mass ratio of 1:20 to obtain a mixed solution. Stir with a magnetic stirring bar at a temperature of 30° C. for 0.5 h.

[0025] (3) The graphene oxide aqueous solution obtained above and the mixed solution of ethyl orthosilicate: graphene oxide: ethyl orthosilicate is added together with a mass ratio of 1:10, and then graphene oxide: hexadecane Trimethylammonium bromide was added into the surfactant at a mass ratio of 1:1, mixed and stirred for 1 hour, while keeping the mixture heated at a constant temperature of 40°C, and then adding ammonia water with pH=13 with a dropper while stirring, ammonia water and silicon The mass...

Embodiment 2

[0030] (1) Mix graphene oxide with water to obtain a solution of graphene oxide, put it in an ultrasonic instrument for further ultrasonic dispersion, the ultrasonic frequency is 500HZ, the temperature is 50°C, the ultrasonic time is 1h, and the concentration is 2mg / ml Graphene oxide solution;

[0031] (2) Mix ethyl orthosilicate and methanol at a mass ratio of 1:30 to obtain a mixed solution. The above solution was placed in a beaker and stirred at a temperature of 30° C. with a magnetic stirring bar for 0.5 h.

[0032] (3) The aqueous solution of graphene oxide obtained above and the mixed solution of ethyl orthosilicate are added together with graphene oxide: ethyl orthosilicate with a mass ratio of 1:20, and then graphene oxide: sixteen Alkyltrimethylammonium bromide was added into the surfactant at a mass ratio of 1:2, mixed and stirred for 1 hour, while keeping the mixture heated at a constant temperature of 45°C, and then adding ammonia water with a pH of 13 with a dro...

Embodiment 3

[0037] (1) Mix graphene oxide with water to obtain a graphene oxide solution, put it in an ultrasonic instrument for further ultrasonic dispersion, the ultrasonic frequency is 1000HZ, the temperature is 25°C, the ultrasonic time is 0.5h, and the obtained concentration is 1mg / ml Graphene oxide solution;

[0038] (2) Mix ethyl orthosilicate and trifluoroethanol at a mass ratio of 1:20 to obtain a mixed solution. Stir with a magnetic stirring bar at a temperature of 30° C. for 0.5 h.

[0039] (3) The aqueous solution of graphene oxide obtained above and the mixed solution of ethyl orthosilicate are added together with graphene oxide: ethyl orthosilicate with a mass ratio of 1:10, and then graphene oxide: polyphenylene oxide Sodium ethylene sulfonate was added into the surfactant at a mass ratio of 1:1, mixed and stirred for 1 hour, while keeping the mixture heated at a constant temperature of 40°C, and then adding ammonia water with pH = 13 with a dropper while stirring, the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com