Preparation method and application of supported copper oxide catalyst

A technology of copper oxide and catalyst, applied in the field of supported copper oxide catalyst Ti2C-CuO-Cu2O, which can solve the problems of complex catalyst process and insignificant reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

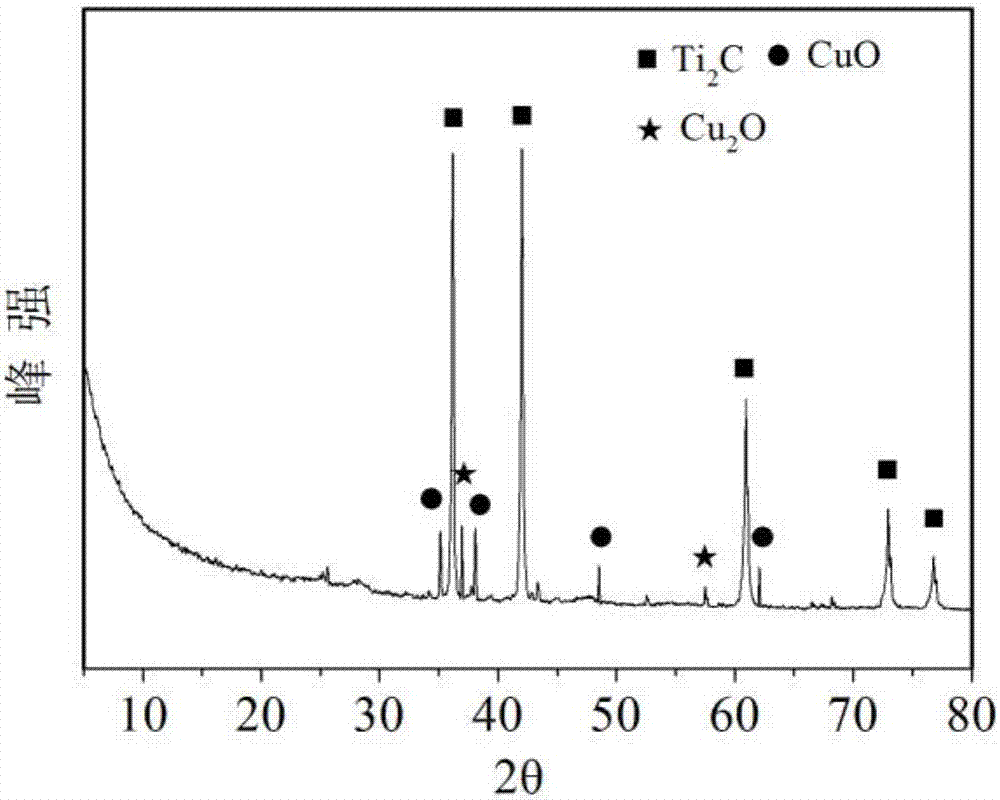

[0025] Ti 2 C-CuO-Cu 2 The preparation of O catalyst includes the following specific steps:

[0026] (1) Mix the titanium powder, aluminum powder, titanium carbide powder, and activated carbon in a molar ratio of 1.5:1.0:0.5:0.5 to a total mass of 50g, and add 5g of absolute ethanol to grind for half an hour, and then stand for 24 hours at 0.1Pa, Vacuum drying at 80°C for 40h, then pressing into pellets, and microwave sintering. The microwave sintering condition power is 2kW, frequency is 2.45GHz, and protected by flowing argon gas, heating rate is 80-100°C / min, heating temperature is 800 -850℃, time is 10 minutes.

[0027] (2) Grind the solid obtained in step one through a 500-mesh sieve, then weigh 2g of powder and 50ml of 20% hydrofluoric acid in a plastic bottle and let stand for 6 hours at room temperature for reaction. Centrifuge the deionized water for 5 times After drying

[0028] (3) Take the dried Ti 2 2g of C powder is placed in 100ml of aqueous solution, and the main co...

Embodiment 2

[0030] Thermal decomposition of pure ammonium perchlorate (AP) without adding any catalyst.

[0031] Take 1.5-2.0 mg of pure ammonium perchlorate with an average particle size of 100μm, place it in an open aluminum crucible, and put the crucible in a thermal differential analyzer. From room temperature to 500℃, the heating rate is 10-15℃ / min, nitrogen Atmosphere protection.

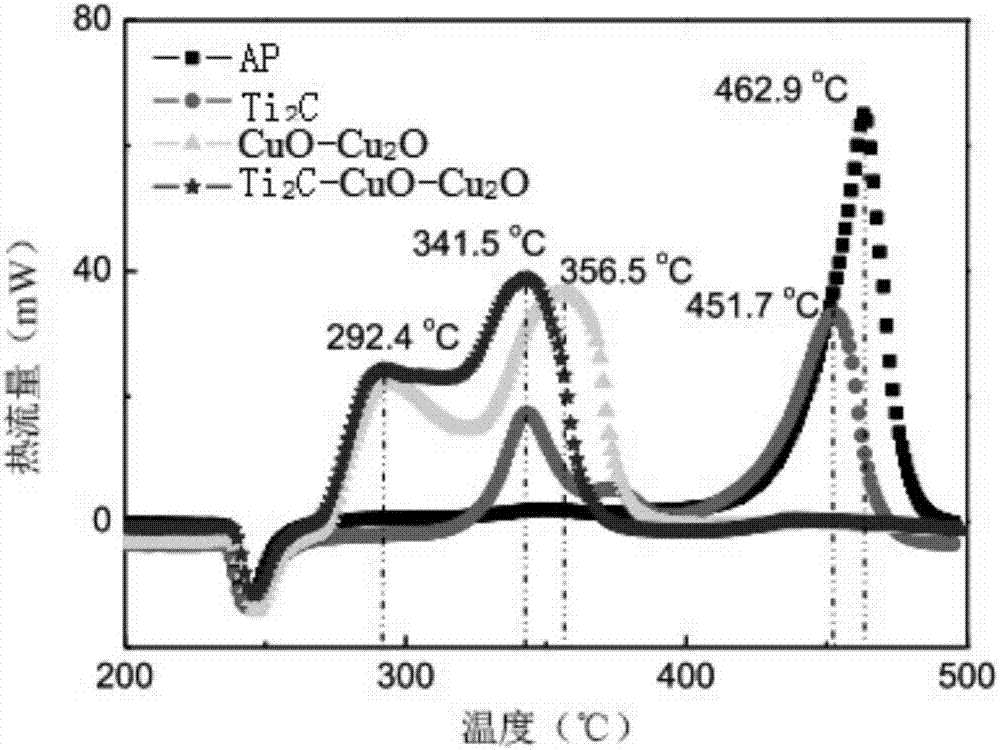

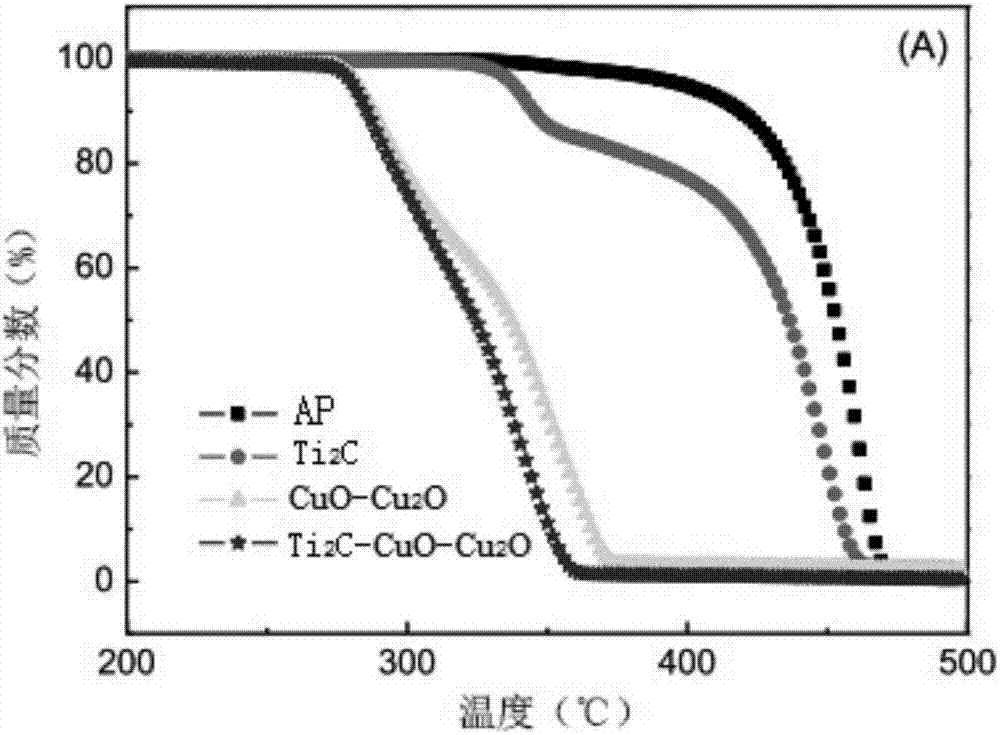

[0032] After testing, the endothermic peak of pure ammonium perchlorate is around 250°C, which corresponds to the crystal transition of ammonium perchlorate from the orthogonal phase to the cubic phase, and the exothermic peaks of pure ammonium perchlorate are at 350°C and 462.9°C. , Respectively correspond to the low temperature decomposition and high temperature decomposition of pure ammonium perchlorate.

Embodiment 3

[0034] Ti 2 C catalyzes the thermal decomposition of ammonium perchlorate (AP). The thermal decomposition steps are the same as in Example 2, with the addition of catalyst Ti 2 C.

[0035] Take the average particle size of 100μm pure ammonium perchlorate and the prepared Ti 2 C. Weigh 1.5-2.0 mg according to a mass ratio of 98:2, place it in an open aluminum crucible, put the crucible into a thermal differential analyzer, from room temperature to 500 ℃, the heating rate is 10-15 ℃ / min, nitrogen atmosphere protection.

[0036] After testing, Ti 2 C has a certain catalytic effect on the thermal decomposition of ammonium perchlorate, but the catalytic effect is not obvious. Ti 2 The addition of C makes the high temperature decomposition temperature of ammonium perchlorate 451.7°C, which reduces 11.2°C, and the weight loss temperature drops 12.4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com