Anti-corrosion high-strength coastal building cement and preparation method thereof

A construction cement and high-strength technology, which is applied in the field of building materials, can solve problems such as low strength and poor corrosion resistance, and achieve the effects of increased strength, good corrosion resistance, and enhanced comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

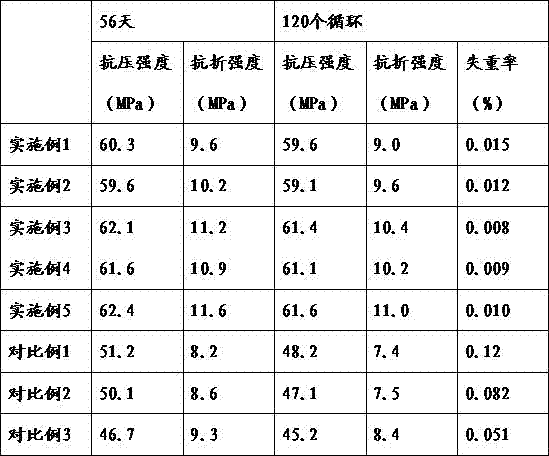

Examples

Embodiment 1

[0023] A corrosion-resistant high-strength coastal building cement, comprising the following raw materials in parts by weight: 30 parts of sulphoaluminate cement clinker; 5 parts of silica fume; 7 parts of gypsum, 20 parts of quartz sand, nitrided 0.1 part of silicon, 10 parts of titanium slag, 1 part of water reducing agent, and 1 part of composite early strength anticorrosion agent.

[0024] The composite early-strength corrosion inhibitor includes 20 parts by weight of vinyl acetate resin, 25 parts of rosin modified phenolic resin, 2 parts of lignin, 3 parts of carbon fiber, 10 parts of triethanolamine, 15 parts of fumed white carbon black, 15 parts of silicon dioxide.

[0025] The preparation method of the composite early-strength anti-corrosion agent is as follows: first mix lignin, carbon fiber, fumed silica and silicon dioxide evenly, then add triethanolamine, vinyl chloride resin and rosin modified phenolic resin in sequence, and then react at 70 degrees for 30 minutes...

Embodiment 2

[0033]A corrosion-resistant high-strength coastal building cement, comprising the following raw materials in parts by weight: 33 parts of sulphoaluminate cement clinker; 10 parts of silica fume; 5 parts of gypsum, 25 parts of quartz sand, nitrided 0.2 parts of silicon, 17 parts of titanium slag, 2 parts of water reducing agent, and 2 parts of composite early strength anti-corrosion agent.

[0034] The composite early-strength corrosion inhibitor includes 25 parts by weight of vinyl acetate resin, 30 parts of rosin modified phenolic resin, 3 parts of lignin, 4 parts of carbon fiber, 12 parts of triethanolamine, 12 parts of fumed white carbon black, 10 parts of silicon dioxide.

[0035] The preparation method of the composite early-strength corrosion inhibitor is as follows: first mix lignin, carbon fiber, fumed silica and silicon dioxide evenly, then add triethanolamine, vinyl chloride resin and rosin modified phenolic resin in sequence, and then react at 80 degrees for 15 minu...

Embodiment 3

[0043] A corrosion-resistant high-strength coastal building cement, comprising the following raw materials in parts by weight: 35 parts of sulphoaluminate cement clinker; 6 parts of silica fume; 8 parts of gypsum, 30 parts of quartz sand, nitrided 0.3 parts of silicon, 20 parts of titanium slag, 3 parts of water reducer, 3 parts of composite early strength anti-corrosion agent.

[0044] The composite early-strength corrosion inhibitor includes 30 parts by weight of vinyl acetate resin, 20 parts of rosin modified phenolic resin, 1 part of lignin, 5 parts of carbon fiber, 15 parts of triethanolamine, 10 parts of fumed white carbon black, 15 parts of silicon dioxide.

[0045] The preparation method of the composite early-strength anti-corrosion agent is as follows: first mix lignin, carbon fiber, fumed white carbon black and silicon dioxide evenly, then add triethanolamine, vinyl chloride resin and rosin modified phenolic resin in sequence, and then react at 75 degrees for 20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com