Nickel residue and slag based cementing material as well as preparation method and application thereof

A slag and base glue technology, applied in the field of nickel slag-slag-based cementitious materials, can solve the problems of large shrinkage, low toughness, poor stability of cementitious materials, etc., and achieve high flexural strength and compressive strength and low requirements. , the effect of saving energy and raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention also provides a preparation method of nickel slag-slag-based cementitious material, which comprises the following steps:

[0027] Mix 500-900 parts of water-quenched nickel slag powder and 100-500 parts of blast furnace slag powder to obtain a powder; mix 0.2-0.3 parts of dispersant, 10-15 parts of fiber and 120-160 parts of water to obtain a dispersed fiber solution; Wherein, before preparing the dispersed fiber solution, the fiber is dipped in an aqueous solution of a surfactant, and the surfactant includes at least one of a fluorocarbon surfactant, a sulfonate surfactant, and a fatty acid surfactant .

[0028] Mix and stir the powder and the dispersed fiber solution evenly to obtain a mixed slurry, add an alkali activator to the mixed slurry, and stir for 3-5 minutes.

[0029] The preparation method of nickel slag-slag-based cementitious material provided by the embodiment of the present invention can effectively stimulate the...

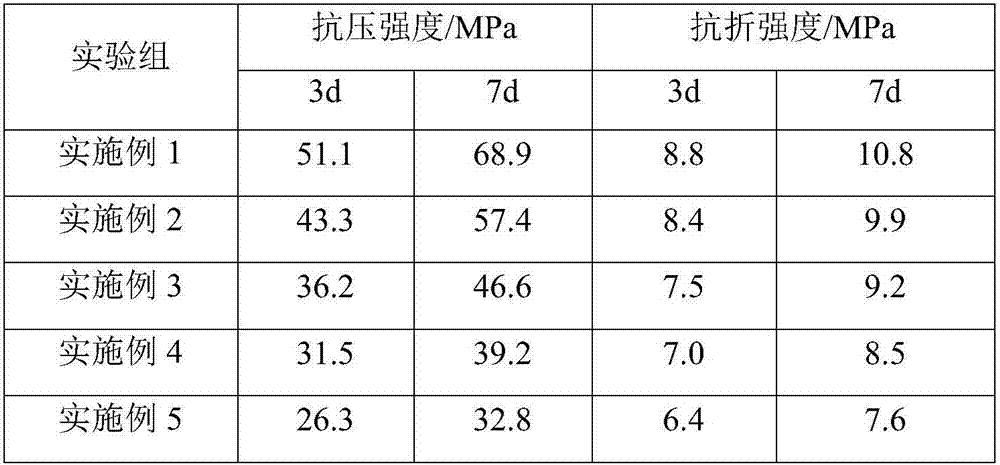

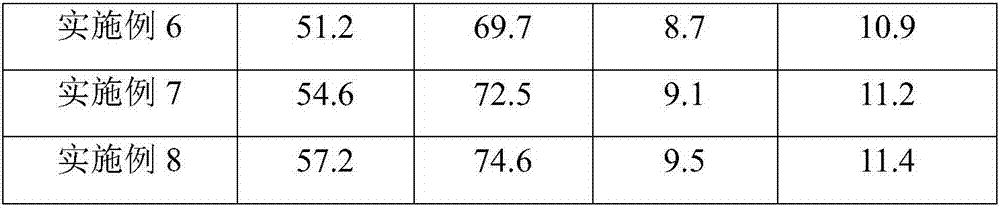

Embodiment 1

[0033] This embodiment provides a nickel slag-slag-based cementitious material, the preparation steps of which are as follows:

[0034] S101. Prepare materials: prepare 500g of water-quenched nickel slag powder, 500g of blast furnace slag powder, 350g of water glass, 15g of polypropylene fiber, 0.3g of carboxymethyl cellulose, and 150g of water. Among them, the specific surface area of water-quenched nickel slag powder is 450m 2 / kg; the specific surface area of blast furnace slag powder is 600m 2 / kg, the length of the polypropylene fiber is 15mm, and the diameter is 32μm.

[0035] S102. Preparation of powder: uniformly mix 500g of water-quenched nickel slag powder and 500g of blast furnace slag powder to obtain a powder.

[0036] S103. Prepare a dispersed fiber solution: 0.3 g of carboxymethyl cellulose, 15 g of polypropylene fiber and 150 g of water are uniformly mixed to obtain a dispersed fiber solution.

[0037] S104. Prepare gelling material: mix and stir the pow...

Embodiment 2

[0039] This embodiment provides a nickel slag-slag-based cementitious material, the preparation steps of which are as follows:

[0040] S201. Preparation of materials: Prepare 600g of water-quenched nickel slag powder, 400g of blast furnace slag powder, 300g of water glass, 20g of sodium hydroxide, 10g of fluororubber fiber, 0.2g of carboxymethyl cellulose, 0.1g of sodium pyrophosphate, and 160g of water. Among them, the specific surface area of water-quenched nickel slag powder is 400m 2 / kg; the specific surface area of blast furnace slag powder is 550m2 / kg, the length of the fluorine rubber fiber is 8mm, and the diameter is 30μm.

[0041] S202. Preparation of powder: uniformly mix 600g of water-quenched nickel slag powder and 400g of blast furnace slag powder to obtain powder.

[0042] S203, prepare dispersed fiber solution: 0.2g carboxymethyl cellulose, 0.1g sodium pyrophosphate, 10g fluororubber fiber and 160g water are mixed uniformly to obtain dispersed fiber solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com