Damping paint for engine

A damping coating and engine technology, applied in the field of damping coatings, can solve the problems of poor noise reduction effect and unsatisfactory engine performance, and achieve good acid, alkali and salt spray resistance, good flame retardancy, and good salt spray resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

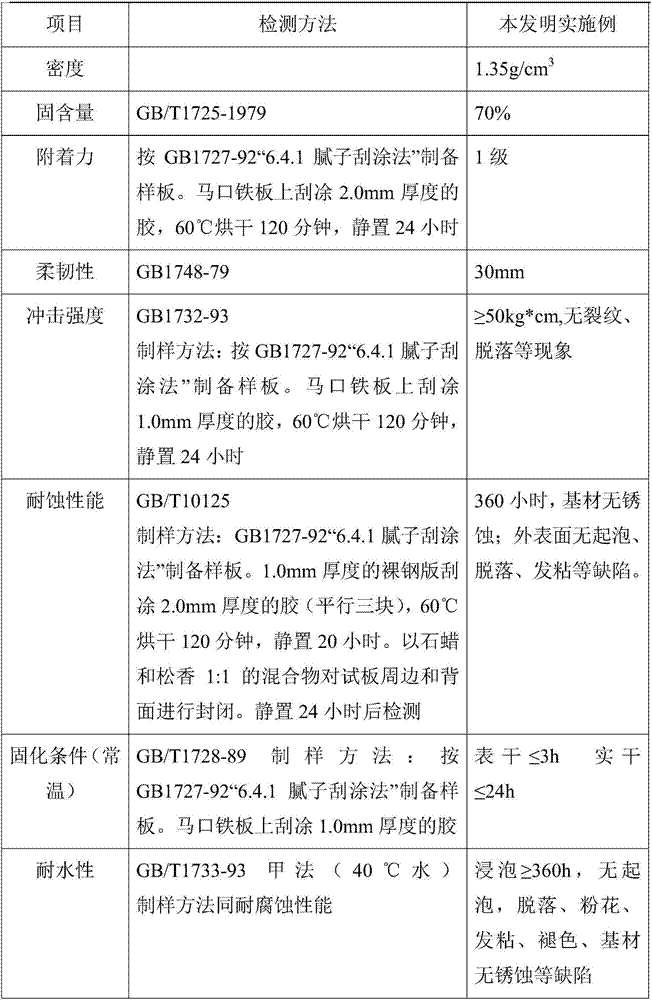

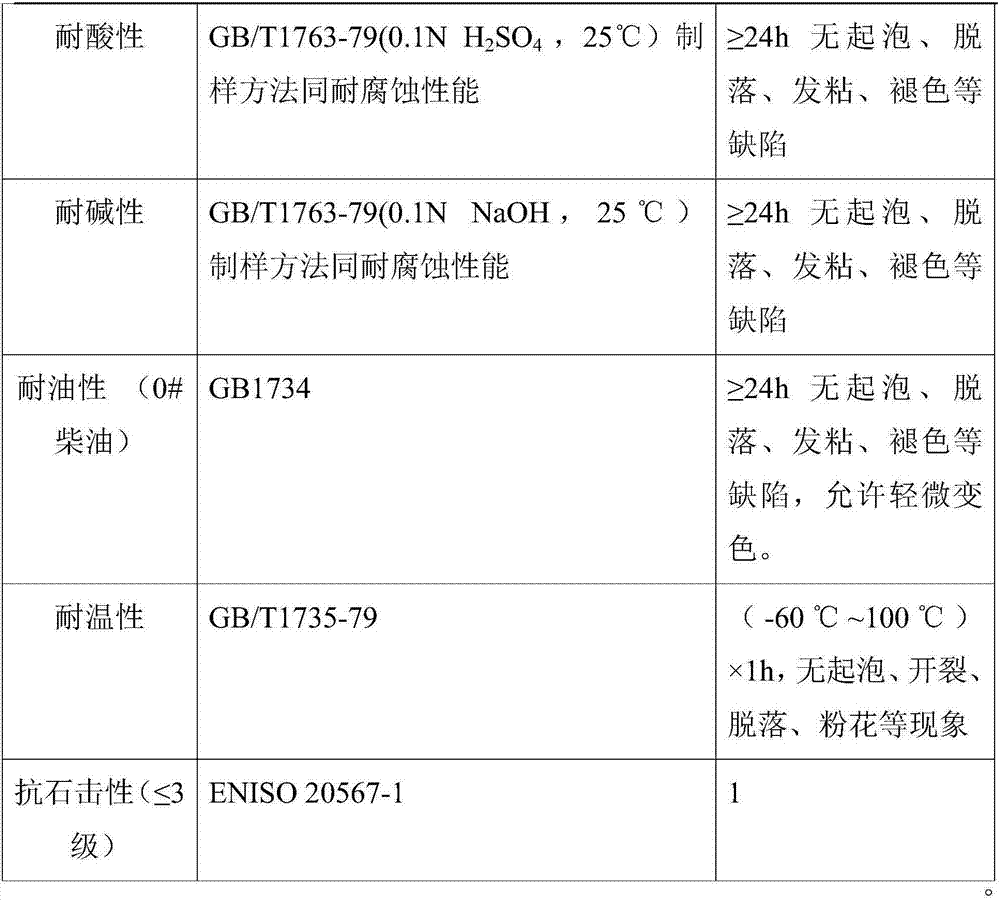

Examples

Embodiment 1

[0030] An engine damping paint, calculated in parts by weight, including the following raw materials: 300 parts of plasticized acrylic emulsion, 40 parts of antimony trioxide, 40 parts of melamine, 20 parts of active magnesium hydroxide, 25 parts of coarse sepiolite, mica powder 50 parts, 75 parts of silica powder, 15 parts of preservative and 5 parts of black paste.

[0031] Calculated in parts by weight, plasticized acrylic emulsion includes the following raw materials:

[0032] 160 parts of butyl acrylate, 100 parts of styrene, 40 parts of methyl methacrylate, 117 parts of α-ethylhexyl acrylate, 12 parts of methacrylic acid, 9 parts of ammonium acrylate, 15 parts of acrylonitrile, 422 parts of water, 1.7 parts of ammonium sulfate, 1.8 parts of oxidation-reduction initiator system, 2.5 parts of pH adjuster, 0.7 parts of emulsifier and 1.5 parts of chloromethyl isothiazolinone. Among them, the oxidation-reduction initiator system is composed of 0.8 part of inorganic reducing agen...

Embodiment 2

[0040] An engine damping paint, calculated in parts by weight, including the following raw materials: 290 parts of plasticized acrylic emulsion, 35 parts of antimony trioxide, 35 parts of melamine, 18 parts of active magnesium hydroxide, 23 parts of coarse sepiolite, and mica powder 45 parts, 70 parts of silica powder, 17 parts of preservative and 6 parts of black paste.

[0041] Calculated in parts by weight, plasticized acrylic emulsion includes the following raw materials:

[0042] 150 parts of butyl acrylate, 90 parts of styrene, 35 parts of methyl methacrylate, 112 parts of α-ethylhexyl acrylate, 14 parts of methacrylic acid, 11 parts of ammonium acrylate, 17 parts of acrylonitrile, 390 parts of water, 1.2 parts of potassium sulfate, 1.4 parts of oxidation-reduction initiator system, 3 parts of pH adjuster, 0.5 parts of emulsifier and 2 parts of chloromethyl isothiazolinone, among which the oxidation-reduction initiator system consists of 0.6 parts of inorganic reducing agent ...

Embodiment 3

[0049] An engine damping paint, calculated in parts by weight, including the following raw materials: 310 parts of plasticized acrylic emulsion, 45 parts of antimony trioxide, 45 parts of melamine, 22 parts of active magnesium hydroxide, 27 parts of coarse sepiolite, and mica powder 55 parts, 80 parts of silica powder, 13 parts of preservative and 4 parts of black paste.

[0050] Calculated in parts by weight, plasticized acrylic emulsion includes the following raw materials:

[0051] 170 parts of butyl acrylate, 110 parts of styrene, 45 parts of methyl methacrylate, 122 parts of α-ethylhexyl acrylate, 10 parts of methacrylic acid, 8 parts of ammonium acrylate, 13 parts of acrylonitrile, 450 parts of water, 2.2 parts of sodium sulfate, 2.2 parts of oxidation-reduction initiator system, 4 parts of pH adjuster, 1 part of emulsifier and 1 part of chloromethyl isothiazolinone, of which the oxidation-reduction initiator system consists of 1 part of inorganic reducing agent and It is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com